Gear planetary sun gear OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

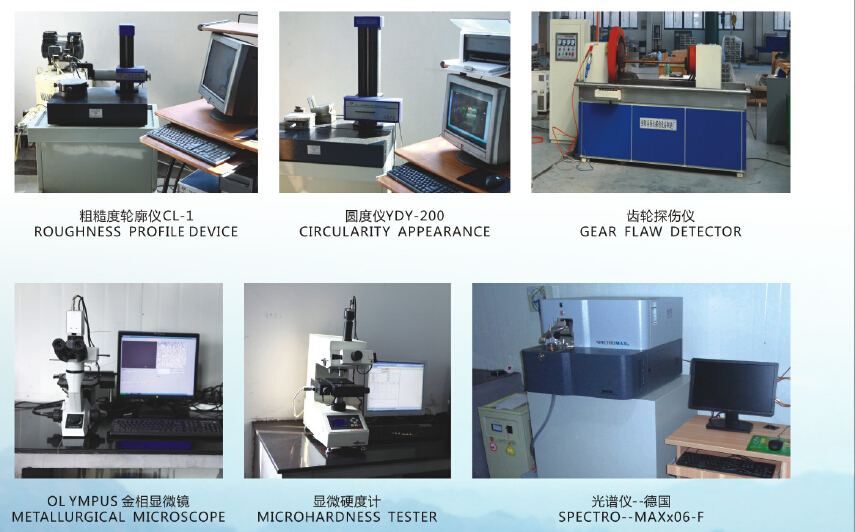

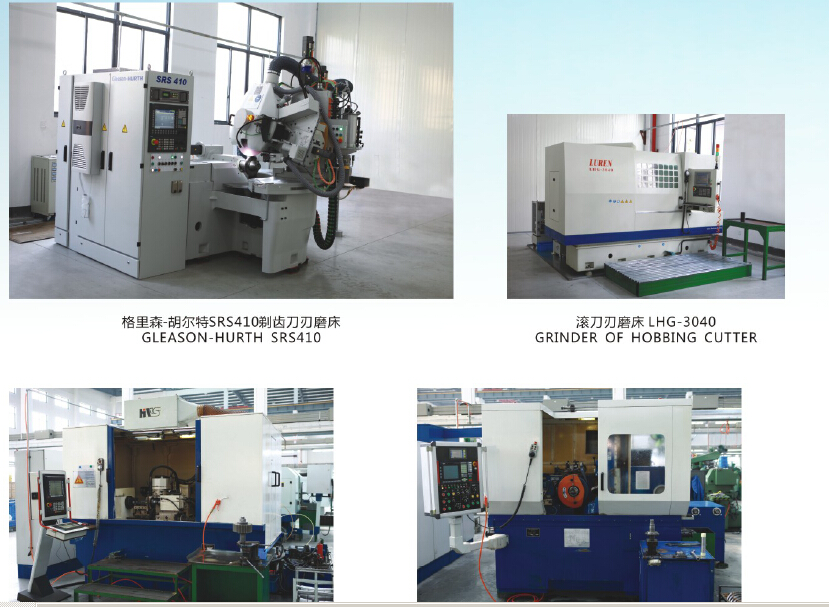

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q:Why does the radial runout of the gear ring reveal only the geometric eccentricity of the gear?

- The workpiece or tool is not positioned properly and is no longer in the correct position.

- Q:The number of planet gear is 20, the drive ratio is 7.5. The number of teeth of solar wheel and ring gear is required

- You drive ratio is really strange, I figure out the sun gear number of 6 points Oh.

- Q:The single stage and single row of gear rings do not move, the sun wheel is the driving wheel, and the planetary gear is driven. How can the speed of the planetary gear and the planetary frame be compared?

- If you have this problem, you can explain it much better. Suppose the number of the inner center teeth is Z1, and the number of teeth on the outer center wheel (what you call the sun wheel) is z2,

- Q:How to remove the flywheel ring gear of the van engine?

- Quite simply, the gearbox is removed, the pressure plate clutch is removed, the flywheel is removed, knocked directly down, and heated until it is red....

- Q:What is the number of teeth of the planetary gear, the sun gear, and the inner ring?

- Generally, the planetary gear has the least number of teeth, followed by the sun wheel and the inner ring gear.There is no definite relation between the number of teeth, but the transmission ratio is different depending on the number of teeth

- Q:For planetary gears, the fixed ring gear connects the sun wheel and the planet carrier, but does it still move?

- Before and after the two planetary sun gear is connected into a whole, called the sun before and after the wheel assembly (2) in front of a ring gear planetary frame of the planetary row and a planetary connection to another one, called the former planet and ring gear assembly

- Q:The car mounted on the flywheel ring gear. How will annealing

- Yes, with the fire relatively fast economic, but it is not the only way, such as the flywheel in the fridge ice for a period of time, or to put it in the oven baked gear for a period of time can, at the same time can be.

- Q:How is the thickness of the outer ring (outer diameter and internal diameter) determined?

- The magnitude of the torque transmission is different and the gear modulus adopted is different. Modulus is not the same

- Q:What gear can be used to evaluate the radial runout of ring gear?

- The radial runout error of gear ring is a standard for gear post test. Generally speaking, it represents the difference of the teeth on the circumference of a gear. Popular point of view, with the detection of the beating of the outer circle almost, but the benchmark is on the teeth.

- Q:How many teeth ring for 11 teeth starter?

- 1, 11 teeth starter with 110 teeth or so gear ring.2, because the starter gear and engine flywheel gear ring transmission ratio is generally about 1 to 10, so the 11 teeth starter with 110 teeth or so gear ring.3, gear ring meaning: flywheel gear ring is heated after inserted on the outer edge of the flywheel, cooled after fastening on the outer edge of the flywheel, used to engage with the starter gear, drive crankshaft rotation, start the engine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gear planetary sun gear OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords