Galvanized C Channel Metal Stud Sizes for Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

purlin and wall beam of steel structure building

The C-shaped purlins have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Product Advantages:

1.We have 120 light steel keel machine,one machine for one specification only,to increase the precision of process.

2.We have over 22 years experiency in producing light gague steel frame.

3.We have business trip to the world each year to have better understanding of the trend of local market.

Main Product Features:

1). Commponents: main tee, long cross tee, short cross tee and wall angle.

2). Unique click design for easy connection.

3). Widely usage for the suspension system of hotel, school, hospital, shopping mall, etc.

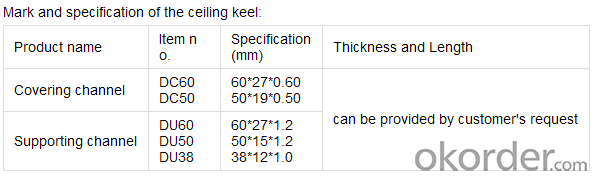

Product Specifications:

Images:

- Q:How to construct double - sided double gypsum board partition wall

- Vertical keel sub-file: According to the location of the wall defense door openings, in the installation of the top keel, according to the specifications of the panel panel width, sub-file size 450mm, less than the modulus of the file should avoid the first box Plate position, so that the edge of the gypsum cover panel is not out of the box. Installation of horizontal card keel: According to the design requirements, wall height greater than 3m should be added to the horizontal card retaining keel, mining core pulling rivets or screws tied to fixed

- Q:Who used the light steel keel gypsum board to do the wall?

- The sound insulation effect than the brick or a little worse but have their own advantages and disadvantages of the small space that is also cheaper than the brick wall is suitable for wardrobe compartment

- Q:Gypsum board partition wall how to sound insulation

- Close the gypsum board to install the keel, filled with rock wool in the keel, and then use the gypsum board with a screw on the keel, you can achieve adequate sound insulation. If you want a better sound insulation, you can use thicker gypsum board.

- Q:Light steel keel wall cheap or cheap red brick

- Now steel is more expensive! Red brick a 4 corner 2 points! It's cheaper to look at yourself!

- Q:What is the relationship between the base board and the liner, whether the keel is between the two layers? Such as light in the wall to do soft package, the basic board and liner how to connect?

- In fact, the soft bag is not soft package, sponge package in a 9mm Austrian Song board, this is the soft bag, and then in order to fixed on the wall, in the light steel keel wall to do a lining you said, That is, I mentioned above the blockboard base.

- Q:Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q:Light steel keel gypsum board partition design should pay attention to what the problem

- Each brand installation and installation methods and characteristics will be different, I will take the Nexu light steel keel brief description of the next.

- Q:I was not a tool in the category, or else I got myself!

- Look at the size of the area. Small words are generally not the unit price of the normal words is to use a gypsum board with a gypsum board is 65 - 75 range.

- Q:How to install damping sound insulation felt

- Noise board installed C100 light steel keel, keel on the inside of the nail pad a layer of sound insulation felt, to avoid rigid connection, keel gap filled with weight 40,35 two-layer sound-absorbing cotton

- Q:Do the decoration of the brethren, I would like to ask: inside the plant to do light steel keel ceiling, partition (are ordinary), package the price of how much?

- Master costs generally between 25-35, if the contractor package material, I suggest you go to the building materials city to buy plaster top, he will be responsible for you to install, gypsum cheap, mainly fee,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized C Channel Metal Stud Sizes for Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords