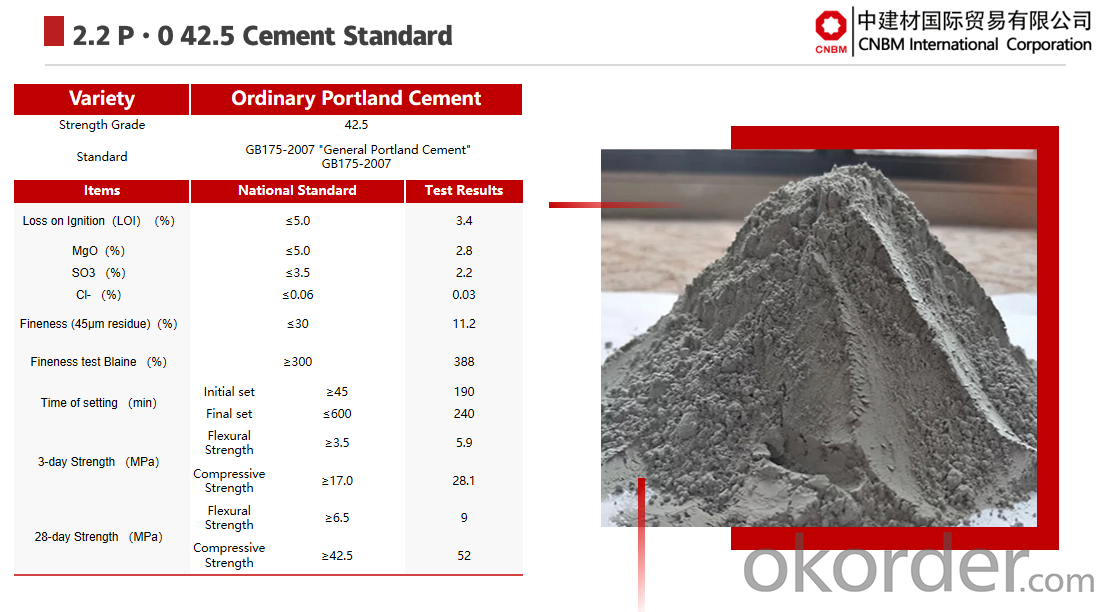

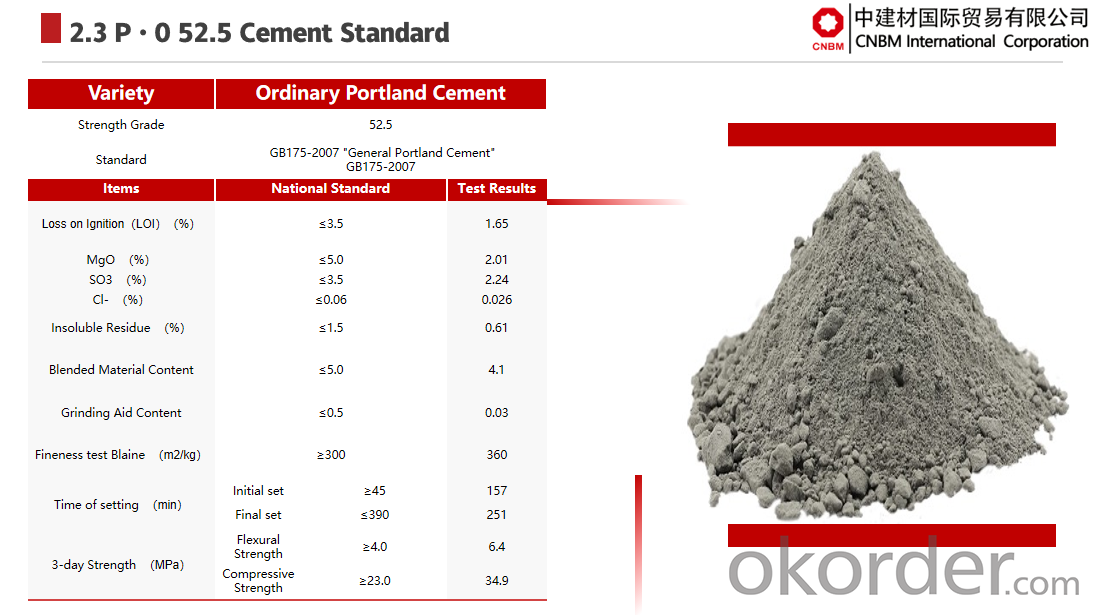

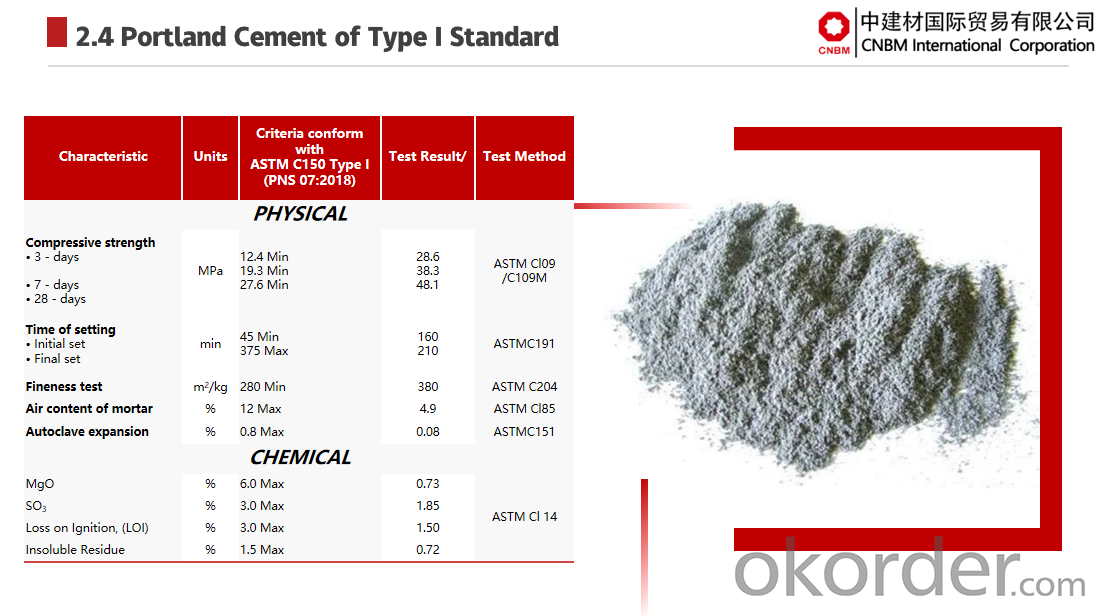

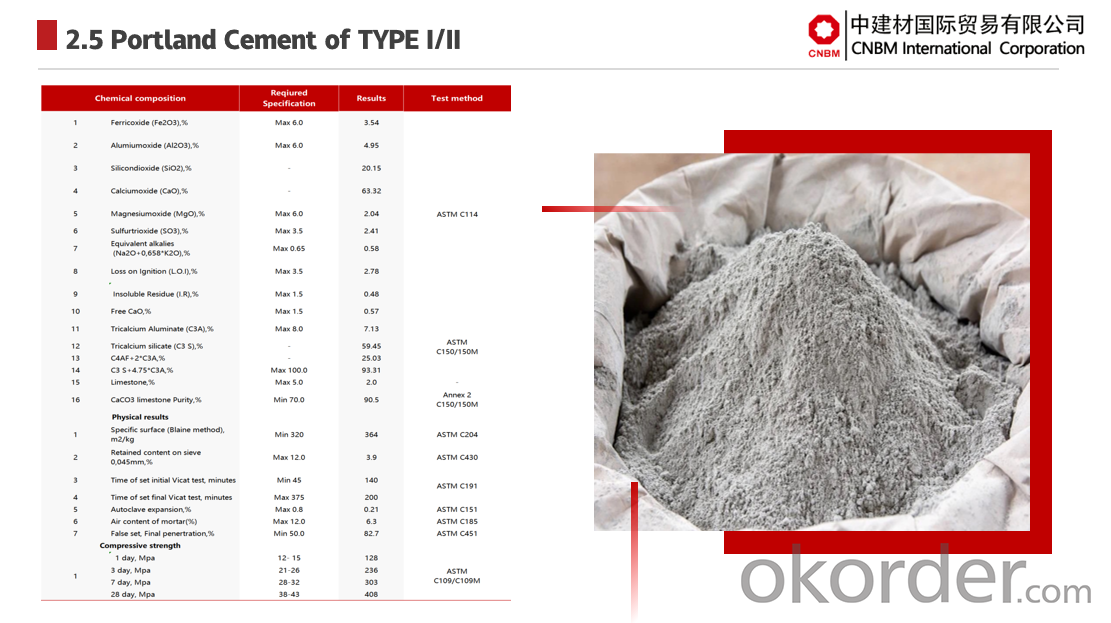

Highest quality for Portland cement 42.5/52.5/Type I Standard/TYPE I/II

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q:whats heavier when set up, cement or plaster?

- There is a reason they use cement for sidewalks and plaster for walls .... can you answer your own question now?

- Q:1.steel2.cement3.sand4.lime

- Lime and silica make about 85% of the mass of cement. However, lime by itself is not used in the production of Portland cement concrete mixtures. Hydrated lime is usually used in the production of asphaltic concrete mixtures. See the links below for more information.

- Q:Which building materials must be witnessed by the sampling inspection? Which decoration materials must be witnessed by the sampling inspection? The best sampling base also told me. Trouble you big. Thank you.

- Trouble you big Thank youCommonly used raw materials to witness the test sample method material name sampling batch sampling quantity and method 1 cement portland cement on the same manufacturer, the same factory the same factory number with the same level of strength

- Q:What is the good introduction for cement?

- Actually cement is nothing but a normal paste or binder.. there is a setting time of a cement .. time of every cement varies depending on the GYPSUM used. In the most general sense of the word, a cement is a binder, a substance which sets and hardens independently, and can bind other materials together. The word cement traces to the Romans, who used the term opus caementicium to describe masonry which resembled concrete and was made from crushed rock with burnt lime as binder. The volcanic ash and pulverized brick additives which were added to the burnt lime to obtain a hydraulic binder were later referred to as cementum, cimentum, c?ment and cement.

- Q:hey im zack and im reseachin portland cement u think u guys help me i want to find out what is it and how its used? THANKS 4 UR HELP AND TIME

- Steel and Portland cement are what the whole world is made out of ! It is one of the two most important substances known to man. It is very strong in compression (squeezing) but very weak in tension (pulling) so you put steel rebar rods in the concrete. Then you have to best of everything. Portland cement can be mixed to have low or high strength

- Q:placing 4 raw eggs in individual cut out egg carton, i space each egg at equal distance apart forming a rectangual shape. then i place a heavy cement block, about 30 pounds, carefully on the 4 eggs. the eggs are able to hold the block up, not breaking. how can this be possible? ned to know by this weekend. thanks

- Hi. When I was a kid, I put A whole raw egg (uncracked) into a jar of white vinegar for a week. This made the egg rubbery and I then bounced it on a cement floor. This really works and little kids love it. Have a nice day.

- Q:please i need advantages and dissadvantages, like how carbide is more expensive, and how high speed steel is resharpable.also a website for references would be nice, thanx in advance.

- Generally, cemented carbide is harder than high speed steel. To last the longest and provide the best cuts It also requires different rake angles relative to the material being cut. A negative rake angle is better with cemented carbide cutting tools and a positive rake angle is better for high speed cutting tools. The material being machined is also a factor in the best rake angle.

- Q:I am working on planning my eagle scout project. It is being done at a local elementary school. Part of it involves building a pathway from their bus area to the entrance so the students don't walk through the grass. The path is about 70 feet long. Would it be cheaper to use cement or to build it out of bricks. Also, which would be easier? Thanks, Johnny.

- If you use cement then you'll either have to have a electric cement mixer or a big wheel barrow. then you'll have to continously lift 50 pound bags of mix and rock into the mixer or if it's a wheel barrow then you'll have to mix it by hand with a shovel and use the correct amounts of water for it to cure correctly and not crack or cure at all. But first you'll have to level the ground by hand as I imagine you wont have a bobcat, then you'll have to build 70 foot long forms from 2X4's and reinforce them with rebar so it stays put. Then you'll have to by type 2 base to line the bare ground and rent a compactor to flaten it. Then if your backs not sore enough you start mixing the cement at an estimate of about 2 tons per cubic yard and do all that math depending on how wide and depth time 70 feet to get the estimate of how much your gonna be in debt for buying all this. So is that the easiest way?? HELL NO! thats why people use mixer trucks to pour side walks. Now if I were you i'd use what they call pavers. Those are the decorative flat bricks you see in secret gardens and what not. They come in all types of shapes and some places carry different colors. This will set you back about $.79 to $1.80 a piece and the average paver is about 12 inches LxW and 1 1/2D. These cover area without crushing the bank account. All you'll need is to level the ground of course, order the right amount base which is a sand and gravel mix and rent a compactor. Level,spread,compact and lay. Thats cheaper and easier as well as giving a custom touch to your project. Good luck dude.

- Q:How do I jack out a 5 ft. high garage cement wall that is bowing in. It keeps getting worse?

- a poured concrete wall is bowing in? or a cement block wall is bowing in? either way , find out why. correct that problem and if it is concrete i dont think you can just jack it out. if its block you may be able to tear some of it out and have it re-laid...

- Q:I want to put the hands on the cement to shape it. I don't want any chemical contamination occuring where the gloves react in any way with the cement.

- This Site Might Help You. RE: what kind of gloves do i use to handle cement? I want to put the hands on the cement to shape it. I don't want any chemical contamination occuring where the gloves react in any way with the cement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Highest quality for Portland cement 42.5/52.5/Type I Standard/TYPE I/II

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords