Drywall Solution Systems for Partition

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m

- Supply Capability:

- 30 Containers/Month m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

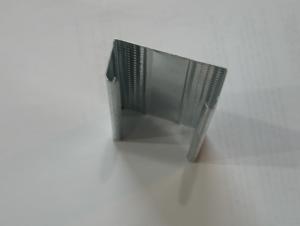

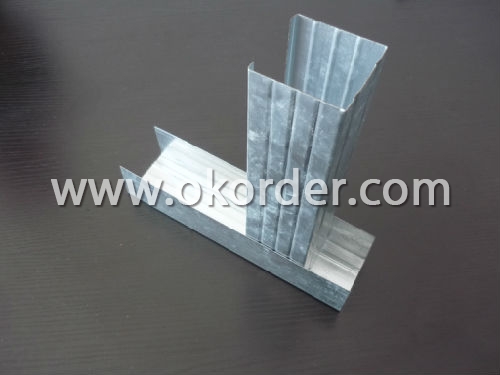

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q:Light steel keel wall to remove the price

- General demolition is to ask the workers, the price of workers depends on the local price, should be the price of each place are different, hope to have a role in you.

- Q:How to construct double - sided double gypsum board partition wall

- Line: according to the design and construction plans, in accordance with the keel width of the elastic line, has been done on the ground or ridge to release the wall position line, door and window openings border line, and put the top, wall keel position edge. To cover the panel of the long, wide sub-file, to ensure that the keel position is correct. Heaven and earth keel installation, along the ball line fixed top, to keel, fixed point spacing should not be greater than 600mm, keel docking should remain straight. Fixed keel keel, keel the end should be fixed, fixed should be solid. Wall, column edge keel with nails or wood screws and walls, column fixed, nail distance of 1000mm.

- Q:Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Are environmentally friendly materials, the state provides the use of materials, but the high cost. There I do not know, I was in Hebei, are generally in our side of the transfer of goods in the past with.

- Q:With light steel keel gypsum board do partition wall price how to count?

- Double-sided labor costs more than 20 yuan per square meter, the material to see the grade of gypsum board and the thickness of the keel. Generally not more than 20 yuan per level. Plus freight and handling costs, loss. Offer 60 yuan per flat can be.

- Q:75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Theoretically, the main factors influencing the sound insulation of the gypsum board wall are as follows: 1) the law of quality: there is a common law for the insulation of the partition, that is, the heavier the material (the greater the surface density) the better the sound insulation. For a single layer of dense uniform wall, surface density for each doubled, the sound insulation in the theoretical increase of 6dB, this law is the law of quality. For the double layer of gypsum board wall, the law of quality plays an important role, that is, to increase the number of layers or thickness of the board can be improved sound insulation. As the keel double wall system sound vibration form is very complex, so the embodiment of the law of quality than the simple single-wall complex. 2) Resonant frequency: any partition wall there is an inherent resonance frequency, when the sound wave frequency and wall resonance frequency, the wall as a whole resonate, the frequency of the sound insulation will be greatly reduced.

- Q:Decorative light steel keel paper gypsum board wall height of 4.1 meters span 6.5 meters need not add structural column, beam

- Light steel keel gypsum board wall with a certain distance set by the vertical galvanized main keel, which is made of thin steel plate C-shaped or I-shaped cross-section of the rigid components, the upper and lower ends should have connectors and structures firmly Fixed, do not need to pour concrete construction column. 4.1 meters high has not seen the practice of pouring concrete belt.

- Q:Gypsum board wall above the good paint glass?

- Not good equipment, the main fear is not bearing, long-term bearing gypsum board may not stand Gypsum board wall is made of light steel keel plus gypsum board made of its light weight, small footprint, easy to disassemble.

- Q:The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- How to get someone else, please eat a meal, or simply do not thousands of dollars that deposit

- Q:Has installed a wooden floor, you can do in the above light steel keel wall?

- Can, to the dragon it to use a little bit of the screw, but look at your floor is still in the cement or above the floor to do in the cement above with a drill to pull the explosion can be a With a long screw, If it is done on the floor of the board it, It is recommended to use a little bit of the screw to play on the above plus gasket To do about the foot line, and the floor color, only to coordinate points

- Q:Light steel keel wall circuit how to wear pipe

- Install the crossed keel (lower threshold). Fixed with a nail, or first drilling, and with the expansion bolts connected to fixed. Installation should be installed according to the center line and edge, both ends of the top to the structural wall (column) surface, the final fixed point from the structure of the facade should not be greater than 100mm; nail or expansion bolt spacing should not be greater than 800mm. Installation should ensure that the keel level and straightness.

1. Manufacturer Overview |

|

|---|---|

| Location | Bazhou, China |

| Year Established | 1994 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | China; Russia; the US; France; Germany; Japan; South Korea; the Middle East; Southeast Asia; Australia; South Africa and many other countries and regions |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 12000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

Drywall Solution Systems for Partition

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m

- Supply Capability:

- 30 Containers/Month m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords