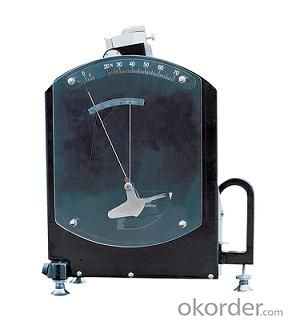

FIBRE BUNDLE STENGTH TESTER

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPECIFICATIONS

YG011 fiber bundle strength tester is an instrument to check the holdingstrength and elongation at breakage of fiber tufts

APPLICATION

STELOMETER is an instrument to check the holding strength and elongation at breakageof fiber tufts.

Holding strength reading on a graduated scale from 0 to 7 kPa (step0.1kPa), elongation reading on a graduated scale from 0% to 50%.

STANDARDS

Standard | ISO 3060 |

Note: this tester can conform to but not limit to the standards above, formore standards conformance, please contact us.

FEATURES

l Calibrate each stelometer by force measuring andelongation devices that are special designed by our company only, ensurepointer indications (force value and elongation) are match to real value andkeep test result stable and high accuracy;

l Special designed table clamps and pressley clamp (we aresupplier for USTER) can hold fiber tufts effectively, and avoid slipping oraffect test as hold tight;

l Read test values of breaking strength and elongationdirectly from two scales after finishing test;

l After fiber tufts breaks, there is no malfunctionmistakes;

l Test result with high accuracy and with good correlationwith yarn strength.

Standard Configuration of Fiber Bundle Strength Tester:

Thickness of sample holding clamp | 11.8mm |

Thickness of separator | 3.2mm |

Test Range | Breaking Load 20N-70N Elongation 0-50% (3.2mm) |

Applying load speed | 10N/s, adjustable |

Correction Coefficient (approxi.) | 0.9-1.1 |

Environment | Temperature be 20±2°C, Relative humidity be (65±3)%) |

Dimension | 320 x390 x160mm |

Weight | 10kg |

- Q:What are the regulations for the air volume of the exhaust fan?

- For a smoke-free partition or smoke clearance height greater than 6.0m non-smoke partition of the room, should be based on the area per square meter of not less than 60m3 / h (single fan minimum smoke should not be less than 7200m3 / H

- Q:What is the meaning of the acceleration of the axial fan?

- It is called "axial flow" because the gas flows parallel to the fan shaft

- Q:What kinds of fans can be divided according to the use of material classification?

- 5. Fan in the form of pressure can also be divided into single, double or multi-stage pressure fan

- Q:What is the role of the fan?

- Ventilation and induced winds for boilers and industrial furnaces; cooling and ventilation in air conditioning and household appliances

- Q:What is the basic principle of an axial fan?

- The cross section of an axial fan is generally a wing profile. The blade may be fixed in position or rotatable about its longitudinal axis. The angle of the blade and the air flow or the spacing of the blades can be adjustable or adjustable. Changing the blade angle or spacing is one of the main advantages of an axial fan. The small blade spacing angle produces a lower flow rate, while increasing the pitch produces a higher flow rate.

- Q:What is the reason for the vibration of the fan?

- Fan inlet and outlet pipe design is unreasonable, causing resonance,

- Q:What types of fans are usually divided into?

- Fan classification can be divided into centrifugal, axial, oblique flow (mixed flow) and cross flow type according to the direction of gas flow.

- Q:What are the models and specifications of the axial fans?

- Axial fans are often used in situations where the flow rate is high and the pressure is low.

- Q:What is the insulation material in the hair dryer?

- Various aircraft on the need for insulation materials are not the same. Aircraft cockpit and cockpit commonly used foam, ultra-fine glass wool, high silica cotton, vacuum insulation board to heat

- Q:How to reduce fan noise?

- Machine discrete noise (rotating noise): the rotation of the impeller. Especially in high-speed, low load conditions, this noise is particularly prominent. Discrete noise is due to the asymmetry between the blade structure and the blade design test rotation formed by the formation of the circumferential flow of the interaction caused by uneven noise, is generally considered to have the following

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FIBRE BUNDLE STENGTH TESTER

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords