Weaving Machinery G

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

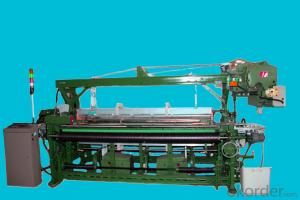

Specification of Weaving Machinery G

1. special medical gauze & bandage weaving machine,plain fabric

2. Machine working width:150cm

3. Fabric max width:145cm

4. Fabric min width:80cm

5. R.P.M:500-600

6. Mechanical take-up,mechanical let-off

7. Thread count:7-20pick per inch

8. Cotton yarn:25s-40s

9. warp beam diameter:800mm ,cloth roller diameter will be 800mm at most.

10. if install big package,the cloth roller diameter will be 1200mm at most.

11. Production capacity:depends on thread count and R.P.M

e.g thread count is 15pick per inch,R.P.M is 600.the production per hour should be 61m/h

Mostly,the production capacity is more than 1000 meter per day.

12. air consumption:0

13.one air pump is installed in the machine

Packaging & Delivery of Weaving Machinery G

Packaging Detail: STANDARD EXPORT WOODEN PACKING.

Delivery Detail: 30 DAYS AFTER RECEIVED ALL ADVANCE

Features of Weaving Machinery G

weaving machine is used to weave crude fibre(cotton,wool,hemp),chemical fibre and blending yarn etc.

- Q:What is the meaning of the acceleration of the axial fan?

- It is called "axial flow" because the gas flows parallel to the fan shaft

- Q:What is the difference between centrifugal fans and centrifugal fans?

- As the inhaled air is absorbed by the exchanger when some heat, so the air is air-cooled. The heat pump absorbed by the exchanger is transferred to the outside through the fluoride force, and the outdoor unit compresses the fluorine force and releases the heat and discharges it into the atmosphere. The main use of gas compression when the heat, the principle of endothermic when the endothermic. The use of fluoride pressure pressure pressure cycle of the indoor heat absorption to the outside.

- Q:What is the principle of explosion-proof fan?

- Suitable for the temperature group T1 ~ T4 environment; impeller made of aluminum alloy processing to prevent sparks caused by the operation, the motor using flameproof motor.

- Q:What is the working principle of the suction blower?

- The principle of suction and hair is the same, are the category of fluid mechanics.

- Q:What is the difference between an axial fan and a centrifugal fan?

- The former motor and fan are generally connected through the shaft, the latter motor is generally in the fan;

- Q:What is the role of the blower in the sewage treatment plant?

- In the operation of the pressure difference using the blower automatically lubricated to the drip nozzle, drip into the cylinder to reduce friction and noise, while keeping the cylinder gas does not return, such a blower, also known as the vane blower.

- Q:What is the operation of centrifugal fans and axial fans?

- When the impeller rotates, the gas enters the impeller from the inlet of the air inlet, and the energy of the gas is raised by the pushing of the blades on the impeller and then flows into the guide vane. The guide vanes change the deflected airflow into axial flow and introduce the gas into the diffuser tube, further converting the kinetic energy of the gas into pressure energy, and finally introducing the working line.

- Q:What is the critical speed of the fan?

- This speed is equal to the natural frequency of the rotor, when the speed continues to increase, close to 2 times the natural frequency amplitude will increase,

- Q:What is the difference between the fan and the compressor?

- The At this time where the first compression, and then with the continuous rotation, the compression chamber volume is reduced. Since the compression process is carried out under full back pressure. Thus inefficient. Noise.

- Q:What is the difference between general-purpose inverter and fan-type inverter

- Machine tool spindle and rolling mill, paper machine, plastic film production line in the coiler, unwinding machine and other required torque, roughly inversely proportional to the speed, which is the so-called constant power load

1. Manufacturer Overview |

|

|---|---|

| Location | Yantai, China |

| Year Established | 1997 |

| Annual Output Value | 500Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 1000 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 50000square meters |

| No. of Production Lines | Above20 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Weaving Machinery G

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords