Weaving Machinery J

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

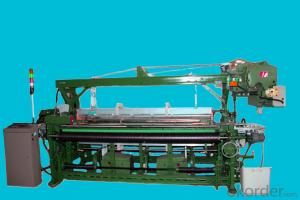

Specification of Weaving Machinery J

1. special medical gauze & bandage weaving machine,plain fabric

2. Machine working width:150cm

3. Fabric max width:145cm

4. Fabric min width:80cm

5. R.P.M:500-600

6. Mechanical take-up,mechanical let-off

7. Thread count:7-20pick per inch

8. Cotton yarn:25s-40s

9. warp beam diameter:800mm ,cloth roller diameter will be 800mm at most.

10. if install big package,the cloth roller diameter will be 1200mm at most.

11. Production capacity:depends on thread count and R.P.M

e.g thread count is 15pick per inch,R.P.M is 600.the production per hour should be 61m/h

Mostly,the production capacity is more than 1000 meter per day.

12. air consumption:0

13.one air pump is installed in the machine

Packaging & Delivery of Weaving Machinery J

Packaging Detail: Pallet packing for long distance

Delivery Detail: 30-35days after reveive deposit or original L/C

Feature of Weaving Machinery J

1.Adopts the cam with eccentric shaft structure for making terry motion and replaces the old type of knocking bill motion structure. It assures the machine having high reliability of making terry and regulating conveniency.

2.Adopts shout crank arm beating-up motion, increasing greatly the beating-up force during weaving that assures the enough strength the weave the heavy towel.

3.thicker weft beating shaft assures enough beating rigidity, it can weaving the wide fabric more than 2800mm

4.adopts optimized six linkages weft insertion structure, make the weft insertion curve more soft

5.the two electromagnets which controlled the terry raising, controlled by technical program which set by electric control system, It can weaving high and low terry

6.the reed seat and other main parts made up of aluminum alloy, make the machine running faster more stable, more than 200rom speed make it the perfect model to replace the low speed towel rapier loom

- Q:Why does the fan start the current?

- Fan is the abbreviation of gas compression and gas transportation machinery in China. Generally speaking, the fans include: ventilators, blowers, wind turbines. Gas compression and gas transport machinery is the conversion of mechanical energy into gas pressure energy and kinetic energy, and the gas transported out of the machinery.

- Q:Axial fan installed directly on the wall exhaust, how to determine its wind pressure?

- If accurate measurements are required, it is necessary to connect a duct and then use a special calibration instrument to measure it.

- Q:What kind of duct valves are required in the exhaust duct and near the fan?

- Mechanical exhaust system due to the fan as a power, can effectively control and distribution of air volume (which is the biggest difference with the natural ventilation), so the system piping (ie duct) need to set the air volume control valve.

- Q:Fire high temperature exhaust fan is a centrifugal fan?

- Identify the axial fan and centrifugal fan, first from the two air flow to look. The air of the axial fan is 180 degrees

- Q:What is the working principle of the suction blower?

- And because the leaf block, can not get the air from the front, only from the rear of the blade to get the air, if the blade made of cylindrical tube, the air on the directional movement, and produce the effect of suction.

- Q:What is the difference between an axial fan and a centrifugal fan?

- Centrifugal roof fans change the flow of media within the duct, while the axial flow of the roof fan does not change the flow of media medium;

- Q:What is the basic principle of an axial fan?

- The guide vanes change the deflected airflow into axial flow and introduce the gas into the diffuser tube, further converting the kinetic energy of the gas into pressure energy, and finally introducing the working line.

- Q:Is the centrifugal fan plugging the air inlet motor?

- If it is to take the energy saving way to block the air intake to save electricity, it would be better to directly change the centrifugal fan control mode is simple and convenient

- Q:How to buy Reiter high-speed centrifugal fan?

- Reasonable choice of blade type: common fan at a certain speed, the back of the impeller pressure coefficient Ψt smaller, the impeller diameter larger, and its high efficiency; the opposite impeller is the opposite.

- Q:What is the difference between a volute fan and a centrifugal fan?

- Centrifugal fan cover is a volute, is to increase its static pressure head and high pressure section of the fan efficiency. After the volute centrifuge fan removed the volute, the majority of the air volume range (high pressure area) of the static pressure head is lower than the centrifugal fan with a volute

1. Manufacturer Overview |

|

|---|---|

| Location | Qingdao, China |

| Year Established | 2003 |

| Annual Output Value | 10-30Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Weaving Machinery J

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords