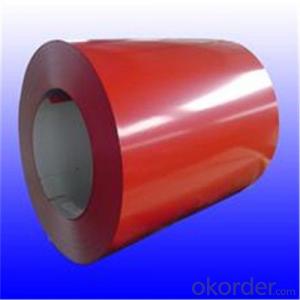

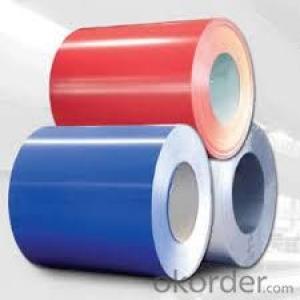

CGCC Color Coated PPGI Pre-painted Steel Coils/ Prepainted Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.CGCC Color Coated PPGI Features:

. Zinc coating :40-275g( as required)

. Thickness:0.17-1.2mm

. Width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

. Coil Id:508m610mm

. Coil Weight: 3-12(as required)

. Color: All RAL color or customized

. Packing: Standard seaworthy packing or according to users' need

. Surface treatment: cremated, oiled, skin passed

. Spangle: regular,small, zero

2. Application of CGCC Color Coated PPGI:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

3.CGCC Color Coated PPGI Specifiction:

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.2mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: | building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

Price: | favorable price | Our Customers | Steel force, Stemcor, Duferco, Samsung , G&G,Hyosung,CNBM | ||

4.CGCC Color Coated PPGI image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- The length of the roll is related to its width and thickness, but not to the extent of the zinc layer.

- Q: What is the average cost of shipping steel coils?

- The average cost of shipping steel coils can vary depending on various factors such as the distance, weight, dimensions, mode of transportation, and any additional services required. To provide an accurate average cost, it would be necessary to consider these specific details.

- Q: What are the different types of packaging for steel coils?

- The different types of packaging for steel coils typically include wooden crates, steel frames, and plastic wrapping. These packaging materials are used to provide protection and secure the steel coils during transportation and storage.

- Q: How are steel coils tested for quality?

- Steel coils are tested for quality through a series of rigorous inspections and tests. These include visual inspections to identify any surface defects, dimensional measurements to ensure proper size and shape, and mechanical tests such as tensile strength and hardness tests. Additionally, non-destructive testing methods like ultrasonic testing and magnetic particle inspection are used to detect internal defects or cracks. These comprehensive quality checks ensure that steel coils meet the required standards and are fit for their intended applications.

- Q: What are the different methods of coil welding for steel coils?

- There are several different methods of coil welding for steel coils, including resistance welding, laser welding, and induction welding. Resistance welding involves applying pressure and passing an electrical current through the coils to create a weld. Laser welding utilizes a high-powered laser beam to melt and fuse the edges of the coils together. Induction welding involves using electromagnetic fields to heat and fuse the coils. Each method has its own advantages and is chosen based on the specific requirements of the application.

- Q: How are steel coils used in the manufacturing of pipelines?

- Steel coils are used in the manufacturing of pipelines by being formed into large cylindrical shapes that serve as the main body of the pipelines. These coils are unrolled and then welded together to create a continuous pipeline, providing strength and durability to transport fluids or gases over long distances.

- Q: How are steel coils processed before they are used in manufacturing?

- Steel coils undergo several processing steps before they are used in manufacturing. The first step is called pickling, where the coils are immersed in an acid bath to remove any surface impurities, such as rust or scale. This helps to improve the surface quality of the steel. After pickling, the coils go through a process called cold rolling. This involves passing the coils through a series of rollers to reduce their thickness and improve their dimensional accuracy. Cold rolling also enhances the mechanical properties of the steel, making it stronger and more durable. Next, the coils are annealed, which involves heating them to a specific temperature and then slowly cooling them. Annealing helps to relieve internal stresses in the steel and improves its formability and ductility. Following the annealing process, the coils may undergo additional surface treatments, such as galvanizing or coating. Galvanizing involves applying a layer of zinc to protect the steel from corrosion, while coating can involve applying various types of paint or polymer to enhance the steel's appearance or provide specific functionalities. Once the coils have been processed and treated, they are typically cut into smaller sheets or strips, depending on the manufacturing requirements. These sheets or strips can then be used in various manufacturing processes, such as stamping, forming, welding, or fabrication, to create a wide range of products, including automotive components, appliances, construction materials, and many others. In conclusion, steel coils undergo a series of processing steps, including pickling, cold rolling, annealing, and surface treatments, before they are ready to be used in manufacturing. These processes improve the quality, strength, and formability of the steel, allowing it to be transformed into a variety of products.

- Q: How are steel coils used in the manufacturing industry?

- Steel coils are used in the manufacturing industry for a variety of purposes such as making automotive parts, appliances, construction materials, and machinery. The coils are typically unwound and processed into sheets or strips, which can then be shaped, cut, or formed into the desired finished product. The versatility, strength, and durability of steel make it a valuable material in the manufacturing process, and the use of coils helps maximize efficiency and productivity.

- Q: So carbon is gas that brakes down to hydrogen and helium before going in...And steel can go a little farther towards sun before evaporating.. 200 degrees closer at leastso steel is full of a heavier gas bomb in my hypothesis and needs to be broken up outside stars(broken down)Is steel capable of going into sun with an element thats wrong wayLike iron has no air to boil outAnd steel goes just as far with carbon in it..Other words can u answer me with..Carbon is already IN the sun and is capable of braking down Carbon INSIDE the star/sunOnly way I see steel boiling is inside and it releases carbon gas at once..carbon bomb

- Carbon NEVER breaksdown into hydrogen and helium. Steel is an alloy of iron that contains carbon. Send either into the sun and they go from being a solid to a liquid to a gas to a plasma as the temperature increases on its approach but neither breaksdown into something else. Carbon as a solid or a plasma is still carbon and the same is true for iron. There are small amounts of most elements in the sun but it is mostly hydrogen.

- Q: What are the different methods of pickling steel coils?

- There are several methods of pickling steel coils, including acid pickling, electrolytic pickling, and mechanical pickling. Acid pickling involves immersing the coils in a bath of acid, typically hydrochloric or sulfuric acid, to remove any scale or impurities on the surface. Electrolytic pickling uses an electric current to dissolve the scale and impurities from the steel coils. Mechanical pickling involves using abrasive materials or mechanical brushes to physically remove the scale and impurities from the surface of the coils.

Send your message to us

CGCC Color Coated PPGI Pre-painted Steel Coils/ Prepainted Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords