Automatic Melamine Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Automatic melamine plywood plate hot press machine

Products detail

Automatic melamine plywood plate hot press machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Automatic melamine plywood plate hot press machine is availale according to your requirements!

Features

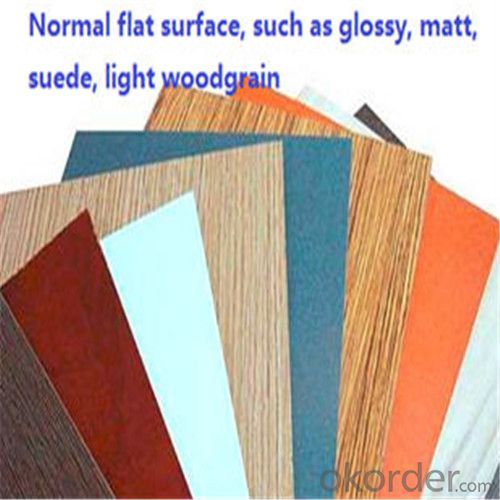

Automatic melamine plywood plate hot press machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Automatic melamine plywood plate hot press machine are for)

Automatic melamine plywood plate hot press machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Automatic melamine plywood plate hot press machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q:What's the difference between an oil-free screw compressor and an oil screw compressor?

- The oil-free screw compressor rotor do not contact each other, and the medium of gas and oil seal are separated, there is no direct contact, so the oil-free screw compressor is widely used in exhaust gas recycling, recycling of coke oven gas and coal seam gas pressure, medium pressure swing adsorption gas containing dust with liquid, gas composition changes in the larger places. The oil free screw compressor can meet the requirement of long time continuous operation of industrial production. The continuous running time is 24000 hours. But the volume efficiency of oil-free screw compressor is lower than that of fuel injection screw compressor, and the general single-stage pressure ratio is not more than 10.Fuel injection screw compressor rotor direct meshing drive, volume efficiency is high, single stage pressure ratio can achieve more than 10. However, because the lubricant and the process of direct contact with the media, so the medium gas requirements are relatively clean, and can not carry a large number of impurities and moisture, otherwise it will affect the lubrication effect of lubricating oil. In addition, the selection of lubricants in the selection of media and gas does not react, are generally dedicated synthetic oil. Therefore, the fuel injection screw is generally used for medium, gas, single work conditions, such as air compressors, refrigeration compressors, etc..

- Q:Can I use the movable air compressor in the coal mine?

- The air compressor station can be built outside, and then the gas supply will be connected to the downhole! Of course, the use of air compressor should be explosion-proof type!

- Q:What's the air compressor room for?

- The air compressor provides compressed air for the rig. The drilling rig's control system is mostly controlled by pneumatic, and it controls the movement of the following parts, such as the gas relay, the gas relay, the control clutch and so on, and completes a control process.

- Q:Non oil water lubrication air compressor

- Brief introduction of Bristol water lubricated oil-free screw compressorThe main characteristics of bestcopco non oil lubricated screw air compressor are reasonable structure, ideal force balance, no radial and axial force in operation, and only rotational force. The single-stage compression ratio is high, the structure size is small: high speed light load, easy to build fluid power lubrication.Bestcopco water lubricated single screw air compressor is a kind of oil-free air compressor series. Water is used as lubricant, which fundamentally solves the possible environmental pollution caused by lubricating oil. Relative to other oil free air compressor, it has the advantages of simple structure, compact structure, low speed, low noise, low exhaust temperature, high thermal efficiency, stable and reliable performance, low power, is the development trend of the new bestcopco oil free air compressor.

- Q:What is the cause of high temperature in oilless lubrication air compressors?

- Main engine rotor or bearing wear, poor heat dissipation and high ambient temperature.

- Q:What is the reason for the low exhaust pressure of the screw compressor?

- Low exhaust pressure usually results from the following conditions:1, large gas consumption, air compressor insufficient air supply, resulting in low voltage operation.2, the intake valve failure, when loading, the intake valve is not fully open, the intake is insufficient, resulting in low exhaust pressure.3, the cooler piercing, resulting in compressed air into the cooler drain, resulting in low voltage operation (in this case, water-cooled models are more common, air-cooled less generally)

- Q:The guarantee value of the oil content in the air of the screw compressor

- Single screw air compressor and worm air compressor, single screw compressor meshing pair is composed of a star wheel 6 head screw and 2 tooth form 11. At the same time with the two wheel worm worm gear even force balance and displacement of double air compressor has the advantages of small size, only 9 cubic meters per minute (9m3/min) worm compressor piston weight is only 1/6. The worm force balance makes the worm compressor have a series of advantages

- Q:What is the meaning of the breaking pressure and the closing pressure in the air compressor? How do you adjust the air pressure and pressure switch?.

- Because the air compressor is a pressure factor automatic control switch, disconnect pressure is to reach this pressure, the air compressor does not work or no output, it should be the highest value

- Q:What's the best air compressor?

- The Quincy compressor has been working in the compressed air technology industry since 1920. Air compressor and vacuum pump professional manufacture and sale of the highest quality. Our products are widely used in the global manufacturing, medical and climate control systems for any industry that requires safe and reliable gas sources. We master air technology and know how to produce excellent quality air technology products. Engineer George Wall, John Kathe and George Gille three people and entrepreneurs and investors Leaton Lrwin and his son Mac together founded in July 20, 1920 wal pump and compressor company.

- Q:The air compressor and the motor use the same electricity. That power is greater

- This is not certain, is an important power for the design and calculate the power, that is the same size as the voltage can be any power, want to know the hands of the motor power can only look at the brand on the show. Or do a series of tests.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Melamine Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches