Auto Robot palletizer Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Name:Robot palletizer

Model:WSD-MD410Ib/160

2. Layout drawing

3. Basic performance description

3.1 Capacity:10800bph(500ml), 6000bph(2L)

3.2 Pack type: (a) Shrink wrapped

3.3 Pay load:60KG

3.4 Dimensions:3354mm*1080mm*3993mm(L*W*H)

3.5Pallet size:1100mm*900mm*150mm

3.6Robot power:7.5Kw,auxiliary power: 12KW

3.7 Compressed air:

(a)Pressure: 0.5MPa (b)Air consumption:max: 100L/min

3.8 Ratio of palletizing:99.5%

3.9Weight(main machine):1940KG,auxiliary equipment weight:2000KG

3.10 Noise : ≤ 75 dB

4.Main equipment configuration: Pallet conveyor,pallet dispenser, ABB 410iB/160 robot,gripper,two speed conveyor etc.

5. Electric configuration:

5.1 Power supply:200-220V(Max.±10%)50Hz 3PH+PE

5.2 Low pressure control:SIEMENS(SHNEIDER)24VDC

5.3 Sensor SICK

5.4 HMI:SIEMENS

5.5 Main switch:SHNEIDER

5.6 Switch button:Ø 22mm

5.7 Proximity switch:Ø18mm

5.8 Control system:SIEMENS

5.9 SEW motor

5.10 DANFOSS inverter

5.11 Other electric equipment protection degree no less than IP54

5.12 Pneumatics:FESTO

5.13 Electromagnetic switch and electrovalve:FESTO

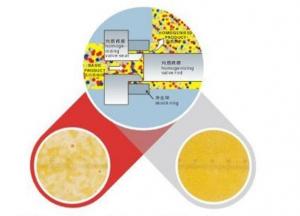

- Q:The principle and function of reverse osmosis equipment

- Indicators and health standards, the output to the pure to pure water, the body is timely to add high quality water the best choice.As RO reverse osmosis technology to produce water purity is the master of all water technology in the highest, cleanliness

- Q:What are the advanced sterilization techniques and equipment

- Milk, which in turn leads to the addition of moisture into the product, which is not allowed in the dairy industry.However, in this case the milk is actually at a temperature of about 140 ° C and the pressure is about three atmospheres; once the pressure is released,

- Q:How does the filling machine work?

- Atmospheric liquid filling machine is based on the weight of the liquid self-flow filling, such filling machine on the liquid viscosity, gas and other large requirements, according to the filling mode is divided into regular filling and fixed irrigation

- Q:Suspension (material) filtration characteristics

- Solid content of 1 ^ -20% of the high viscosity material filter, you can use continuous pressurized cylindrical filter or continuous pressure disc filter.

- Q:Filling machine installation precautions

- 4, with the handle shake the machine, check the machine is running in the correct direction (facing the motor spindle counterclockwise direction), the machine must be protected ground

- Q:Filling machine on the liquid filling when why there are bubbles

- 4, filling the process of foaming and raw materials have a great relationship.

- Q:How to choose the best water treatment equipment

- Moreover, the use of manufacturers to see the accessories, the main accessories with the import of the better, stable performance.

- Q:What is the composition and function of the water treatment system?

- Central soft water machine: soften the household water, to eliminate the uncomfortable hard water, clothes supple, the skin is not tight, to protect wading equipment.

- Q:The filter material is preconcentrated

- The fine particles entrained in the solid phase of the suspension are the main reason for the difficulty in filtration during the filtration process. The fine particles enter the medium and deposit on the surface of the medium to form the slurry layer, so that the filtrate channel is extremely narrow and the filtration resistance is very fast

- Q:What is the edge sealing machine?

- The crown cover placed in the bottle, the machine under the gland mold pressure, the crown cover the ripple around the squeeze shrink, stuck in the neck of the neck of the bottle, causing the bottle and the bottle between the mechanical hook even,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Auto Robot palletizer Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords