Conveying System For Bottle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Equipment Overview:

The operation efficiency of production line, and has a lot to do with the configuration of conveying system. For the configuration of conveyor line, consider and guarantee that a brief stop of the after machine (for example: change the label, etc.) has no influence on the front end equipment, at the same time the front and back equipment should be able to connected well together, to make the whole production line to achieve high efficiency. On our production line arrangement we fully consider the relationship between customer investment and production line efficiency, on the basis of the introduction of foreign technology, which can well meet the above requirement. The system adopts the advanced foreign technology, the mechanical structure for the new design, most components by stamping or bending forming, has advantages of good rigidity, light weight, good interchangeability. For the Transmission way, reliable operation, convenient maintenance, suitable for conveying from 40 ~ 110 mm diameter bottle.

Non-Pressure conveying system relies on and automatic differential speed signal acquisition and real-time feedback control system, can achieve that multiple rows of bottles smoothly change to the single row in the state of running , not squeeze each other. Electric control system adopts that PLC control the running of full bottle conveying buffer system, automatic acceleration and deceleration of speed, and automatic buffer.

Specifications

1.Barrel Water Filling Machine

2.Stable conveying

3.Certificate: CE, SGS, ISO

Full Bottle Conveying System

Full Bottle Conveying System

Description:

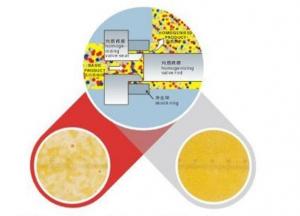

The working efficiency of the production line is largely decided by the conveying system. When there is occasional stop on the downstream packaging system (e.g. label change), the forepart of the production line cannot be effected. At the same time, the transferring system must connect the equipments in the forepart and rear part well. Newamstar’s product is of good rigidity, light weight and good exchanging ability. It is applied for bottles whose diameter is φ40~φ110 mm.

Non-pressure conveying system enables the multi conveying lines become single conveying line during work. The electric control system adopts PLC to control the running of filled bottle conveying, to realize the automatic speed accelerating or slowing and automatic buffering.

Filled Bottle Conveying System

- The design of electrical control is advanced and rational, we can design control mode, select electrical control components according to clients layout, to improve the conveying stability.

- With centralized lubrication system, ANSI304 stainless steel water collector, drainage pipeline, etc.

- Imported sensor checks bottle quantity on conveyor and adjust line speed by inverter.

- Set the switch according to conveying system layout or customer reasonable requirement, for the conveying stability.

- Chain technology is of REXNORD,Main electric elements are all from SIEMENS.

-design of electric control is reasonable and advanced. The electric elements and control way could be selected according to the customer’s need.

-The control switch is located according to the conveying system’s layout and the customer’s need

- Q:Public water treatment system

- Main use: daily water treatment works, swimming pool filtration and disinfection project, aquaculture ornamental fish water, water-saving irrigation, desert brackish water desalination system, desalination system, electroplating wastewater treatment metal recycling, domestic sewage treatment and reuse, product cleaning water recovery

- Q:For the quality of the beverage produced by the filling machine

- The landlord asked the "production of beverage quality problems" that may only be related to your raw materials, you buy the raw material skill is the quality problem, or raw material characteristics, during filling problems, you know, even the automatic filling machine also

- Q:What is the purified water equipment?

- Thus creating a favorable condition for the subsequent disinfection process.

- Q:The working principle of Edi ultrapure water equipment

- Electrode between a pair of electrodes, usually by the film, the sun film and the partition (A, B) alternately arranged to form a thick room and light room (that is, cation can be through the sun, the anion can be through the yin

- Q:What is the purified water preparation system?

- Because of its simple operation process, desalination and heat removal in addition to high efficiency, and more economical.

- Q:What is the electronic cleaning device?

- Because the large amount of calcium and magnesium ions in the water system is difficult to be effectively treated in the early stage, the subsequent water system precipitates CO2 under the action of temperature to produce CaCO3 and MgCO3 which are slightly soluble in water.

- Q:What do the filling crew do?

- 1, operation filling machine normal production, cleaning, running.

- Q:What is the filter equipment used

- In the selection of filtration equipment before the first response to the production of materials need to filter a clear understanding of the situation.

- Q:The main causes of the first failure are the following

- If the speed is too fast, the seal has not yet been heated to be driven by the traction roller to the cold at the cooling treatment, and naturally fail to meet the quality requirements.

- Q:Choose what is suitable for the filter media

- The media characteristics are mainly reflected in the retention capacity, permeability (or breathability), temperature resistance, chemical resistance, mechanical strength and easy to peel the cake and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Conveying System For Bottle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches