3-Side Sealing Filling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 30 Sets/month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specifications of 3-Side Sealing Filling Machine:

1. Brand new automatic control system, Mitsubishi programmable controller, and Proface touch screen human-machine interface, with convenient operation.

2. The production efficiency of the high speed machine is greatly enhanced. The output of milk packed by bag of 250ml can reach 7200bags/hour.

3. The pneumatic control horizontal sealing, vertical sealing, film connecting and sealing quality have been greatly enhanced. It can connect the films and carry out continuous production without stopping the machine, which can reduce the consumption of packing materials and milk.

4. Stepping motor drives the main traction, which avoids the danger of oil dirty pollution caused by chain transmission’s passing through the filling room?

5. Special temperature control system and sealing and cutting structure can greatly enhance the pouch producing rate and reduce the production consumption of film.

6. Complete stainless steel frame, which is nice-looking and durable.

7. Internationally first class electric and pneumatic components are adopted, which guarantee good operation of equipment.

2.Usage of 3-Side Sealing Filling Machine:

High speed, high sealing and cutting quality, high filling precision, high automatic control, low malfunction rate and low operation and maintenance cost. It is mainly applied for packing of pasteurized milk, fresh milk and yoghourt etc. low temperature products, or the long life products such as twice sterilization products.

3.Packaging & Delivery of 3-Side Sealing Filling Machine:

One set packed into 20GP container.

By sea or by air all available.

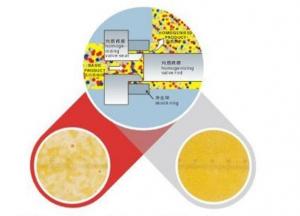

- Q:The structure of the sealing machine

- And by the speed control device to adjust to the required speed.

- Q:What is the ultrafiltration device?

- Equipment, small size, simple structure, low investment costs;

- Q:What is the activated carbon filter tank?

- Can be very effective in absorbing impurities in water, especially organic matter and microorganisms.

- Q:What is the brewing machine?

- piston structure designed automatic quantitative liquid sub-installed for hospital preparation room, ampoules

- Q:What type of sterilization equipment is dedicated to sterilization?

- The ozone-inactivated virus mechanism destroys viral ribonucleic acid (RNA) or deoxyribonucleic acid (DNA) by oxidation.

- Q:The main causes of the first failure are the following

- As long as the total thickness of the bag has increased, the heat sealing temperature must be increased accordingly.

- Q:Food heating sterilization equipment which is good?

- Heat sterilization, then look at the characteristics of sterile materials

- Q:The Structure Principle of Anti - drip Leakage of Filling Machine

- The other is the pressure inside the storage tank is higher than the pressure in the bottle, the liquid pressure into the bottle by the pressure, high-speed production line to use this method.

- Q:Filling machine production capacity 5000bph What does it mean

- Filling machine is mainly a small class of packaging machine products, from the perspective of the packaging of materials can be divided into aerosol filling machine, gas filling machine, liquid filling machine, paste filling machine, powder filling machine

- Q:What is the edge sealing machine?

- It is the first cylindrical metal cover in the bottle, with a roller rolling its bottom, so that its varus deformation, tighten the mouth of the mouth and seal it.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 450 Million |

| Main Markets | Mid East, Eastern Asia, Africa, Eastern Europe, Southeast Asia |

| Company Certifications | National Industrial Products Production License |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Guangdong |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 200-300 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 350,000 square meters |

| No. of Production Lines | Above 20 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

3-Side Sealing Filling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 30 Sets/month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords