AIR FILTER BFC-4000 5”

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

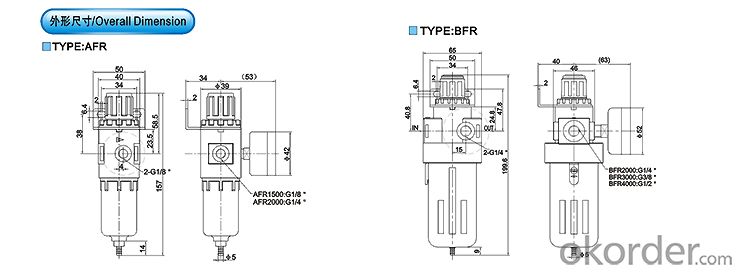

Type

small size

middle size

Joint pipe bore

1500:G1/8"

2000:G1/4"

3000:G3/8"

4000:G1/2"

Drian Type

Blank: Differential Drain

D: Automatic Drain

- Q:I don't understand. To the assembly of pneumatic components factory, so that the understanding of the product is faster?. I hope there are teachers in this area to help answer. How long is the assembly done?

- The light assembly is not enough, but also know its working principle, if you have time to go to the assembly shop of pneumatic machine practice, various pieces of mastery is impossible, as long as the common thing to do that on the line, almost a year

- Q:What are the main parameters of pneumatic components?

- There are many kinds of pneumatic components. In general, they can be divided into auxiliary components, control elements and actuating elements:Auxiliary components: filters, pressure reducing valves, oil mist, etc., the main parameters are the pipe diameter, flow size, filtering accuracyControl components: mainly electromagnetic valve, the main parameters are voltage, nozzle diameter, bit through function, installation method, flow, single coil or double coil, etc.Pneumatic actuator: the main parameters is the cylinder stroke, installation, installation size, positive reaction, etc.Basic parameters on these, special occasions special treatment

- Q:What are the pneumatic components used in the industry?

- The garbage door opening and closing, pneumatic wrench, pneumatic picks and so on, too much.

- Q:I would like to ask you, pneumatic components, including what mechanical parts?

- Pneumatic actuating element (cylinder), control element (solenoid valve)

- Q:How much is the dynamic pressure gas picks

- Most of the work pressure on the use of pneumatic equipment in the industry is about 0.55Mpa. (i.e.: 5.5kg/cm2 or so).

- Q:What are the classifications of cylinders in pneumatic components?

- Classification of according to the structure characteristics of the cylinder1. piston cylinder. Including: ordinary single acting cylinder, double acting cylinder, double piston rod cylinder, cylinder, cylinder, differential number of tandem cylinder, an impact cylinder, Rodless cylinder, piston cylinder, magnetic stepping cylinder, supercharging cylinder, gas-liquid pressurized cylinder, oil damping cylinder, gear rack cylinder, cylinder, cylinder special cable.2. film type cylinder. It includes single acting film cylinder and double acting film cylinder.3. swing cylinder (or vane). There is a single leaf oscillating cylinder and two blade oscillating cylinder.

- Q:In turn, the pneumatic components follow the inlet direction. Why?

- Because, first of all to water, oil and gas, dust and impurities by water filters from the compressed air source, thereby purifying air; then, in order to adjust pressure to stabilize the gas pressure through the purified gas through the valve;

- Q:It is a standard pneumatic drive element. What functions does it have on the cylinder?

- Two 、 wear rule of cylinder and its reason(1) the wear rule of cylinderFrom the longitudinal section of the cylinder (along the axis of the cylinder): irregular, tapered, or tapered". The maximum wear parts: cylinder with the piston at TDC on the first piston ring corresponding to the upper reach of the piston ring wear, cylinder order form "". Under special circumstances, the location of the maximum cylinder wear in the middle (drum). On the same engine, the wear of different cylinders is different. The wear of the front wall of the first cylinder and the back wall of the last cylinder of the water cooled engine is more serious.From the cross section of the cylinder: uneven wear, wear irregular oval. Each cylinder along the circumferential direction of the maximum wear parts: general is the intake valve near the wall opposite the maximum wear.

- Q:What about leakage of pneumatic components?

- Of course, part of the die-casting cylinder, it can not change seals it (open it will not go back)

- Q:What are pneumatic components?Pneumatic components include:

- Pneumatic component is the work done by the force produced by the pressure or expansion of the gas to realize the mechanical drive and control

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AIR FILTER BFC-4000 5”

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords