All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining petrochemical cracking furnaces?

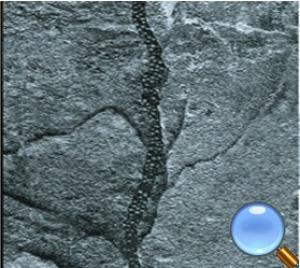

Yes, monolithic refractories can be used for lining petrochemical cracking furnaces. Monolithic refractories are known for their excellent thermal shock resistance, high-temperature stability, and ability to withstand harsh chemical environments, making them suitable for the demanding conditions inside petrochemical cracking furnaces.

How do monolithic refractories perform in oxidizing liquid or solid environments?

Monolithic refractories perform well in oxidizing liquid or solid environments due to their high heat resistance and chemical stability. These refractories are designed to withstand high temperatures and resist chemical reactions with oxygen, making them suitable for applications in oxidizing conditions.

What are the safety considerations when installing monolithic refractories?

When installing monolithic refractories, there are several important safety considerations to keep in mind. Firstly, it is crucial to wear appropriate personal protective equipment (PPE) such as gloves, goggles, and respiratory protection to prevent any direct contact with the refractories or inhalation of harmful dust particles.

Additionally, it is important to ensure proper ventilation in the installation area to minimize the accumulation of potentially hazardous fumes or gases. Adequate training and supervision should be provided to the installation personnel to ensure they understand the proper handling and application techniques, minimizing the risk of accidents or injuries.

Furthermore, it is essential to follow the manufacturer's instructions and safety guidelines while working with monolithic refractories. This includes using the correct tools and equipment for installation, as well as ensuring that the refractories are properly cured and dried before subjecting them to high temperatures.

Regular maintenance and inspections should be carried out to identify any signs of wear, damage, or deterioration in the refractories. Any issues should be addressed promptly to prevent potential safety hazards.

Overall, prioritizing safety measures throughout the installation process will help minimize the risk of accidents, protect the health of workers, and ensure the effective and long-lasting performance of monolithic refractories.

Are monolithic refractories suitable for use in cement kilns?

Yes, monolithic refractories are suitable for use in cement kilns. Monolithic refractories offer excellent thermal stability, corrosion resistance, and mechanical strength, making them an ideal choice for the extreme operating conditions found in cement kilns. They can withstand high temperatures and chemical reactions, ensuring prolonged service life and improved efficiency in cement production. Additionally, their flexibility allows for easy installation and repair, reducing downtime and maintenance costs.

How do monolithic refractories perform in terms of thermal insulation?

Monolithic refractories exhibit excellent thermal insulation properties due to their low thermal conductivity, allowing them to effectively retain heat and prevent heat loss.

Wholesale Monolithic Refractories from supplier in Namibia

Whether you are in need of Monolithic Refractories for the construction, steel, cement, or petrochemical industries, we have the expertise to meet your specific requirements. Our team of experienced professionals is dedicated to providing top-notch customer service, from initial inquiry to after-sales support.

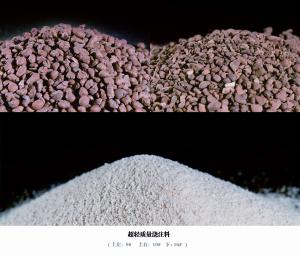

We understand the unique challenges and demands of the Namibian market, and we strive to deliver tailored solutions that meet the highest quality standards. Our network of trusted suppliers ensures that we can offer a wide range of Monolithic Refractories options, including castables, plastics, ramming mixes, and gunning mixes, among others.

In addition to our sales and technical support services, we also offer competitive pricing and efficient logistics solutions. We work closely with our clients to understand their specific needs and deliver timely and cost-effective solutions.

At CNBM Namibia, we take pride in our commitment to excellence and our ability to deliver reliable and high-quality Monolithic Refractories products. Contact us today to discuss your project requirements and discover how we can help you achieve success in Namibia.

We understand the unique challenges and demands of the Namibian market, and we strive to deliver tailored solutions that meet the highest quality standards. Our network of trusted suppliers ensures that we can offer a wide range of Monolithic Refractories options, including castables, plastics, ramming mixes, and gunning mixes, among others.

In addition to our sales and technical support services, we also offer competitive pricing and efficient logistics solutions. We work closely with our clients to understand their specific needs and deliver timely and cost-effective solutions.

At CNBM Namibia, we take pride in our commitment to excellence and our ability to deliver reliable and high-quality Monolithic Refractories products. Contact us today to discuss your project requirements and discover how we can help you achieve success in Namibia.

Hot Search

- Monolithic Refractories in Cameroon

- Ceramic Fiber Products in Turkey

- Refractory Bricks in Senegal

- Raw Materials For Refractory in Kuwait

- Raw Materials For Refractory in Chad

- Refractory Bricks in Netherlands

- Monolithic Refractories in Qatar

- Refractory Bricks in Comoros

- Refractory Bricks in Serbia

- Raw Materials For Refractory in Barbados