All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

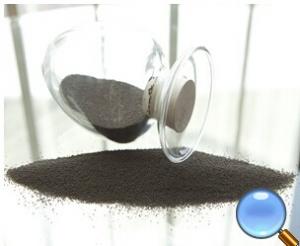

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do monolithic refractories perform in burner applications?

Monolithic refractories perform exceptionally well in burner applications due to their ability to withstand high temperatures, resist thermal shock, and provide excellent insulation properties. They offer superior strength, durability, and erosion resistance, ensuring long-lasting performance and optimal combustion efficiency in burner systems.

How do monolithic refractories compare to gunning refractories in terms of cost?

Monolithic refractories generally have a higher initial cost compared to gunning refractories. However, in the long run, monolithic refractories tend to offer better cost-effectiveness due to their longer lifespan, reduced maintenance requirements, and improved overall performance.

What are the limitations of using monolithic refractories?

One limitation of using monolithic refractories is their lower thermal conductivity compared to traditional brick refractories. This can result in slower heat transfer and longer heating and cooling times. Additionally, monolithic refractories may have a shorter lifespan and require more frequent maintenance due to their susceptibility to cracking and spalling.

Are there any limitations to using monolithic refractories?

Yes, there are several limitations to using monolithic refractories. Firstly, they have a limited lifespan compared to other refractory materials, such as bricks or tiles. Monolithic refractories are more prone to wear and erosion, especially in high-temperature and abrasive environments, which can result in shorter service life. Additionally, monolithic refractories have lower thermal conductivity compared to dense bricks, which can affect their ability to transfer heat efficiently. Moreover, the installation process of monolithic refractories can be more complex and time-consuming, requiring skilled labor and specialized equipment. Lastly, monolithic refractories are generally more expensive compared to traditional refractory materials, making them less cost-effective in certain applications.

How do monolithic refractories perform in corrosive environments?

Monolithic refractories generally perform well in corrosive environments due to their high resistance to chemical attack and erosion. They are able to withstand harsh conditions and provide excellent protection against corrosion, making them a reliable choice for applications where corrosive substances are present.

Wholesale Monolithic Refractories from supplier in Qatar

With our expertise in supplying Monolithic Refractories in Qatar, we are dedicated to meeting the specific needs of customers in this region. Whether you require sales, quotations, or technical support services, we are committed to providing a diverse range of Monolithic Refractories products. As a subsidiary of CNBM, a well-known Fortune Global 500 company, we have the capacity to offer comprehensive procurement solutions for Monolithic Refractories in Qatar. Our extensive product portfolio is backed by years of market development experience in Qatar, enabling us to offer valuable insights and expertise for your projects.

Hot Search

- Monolithic Refractories in Uganda

- Ceramic Fiber Products in Romania

- Refractory Bricks in Senegal

- Raw Materials For Refractory in Iceland

- Monolithic Refractories in Oman

- Monolithic Refractories in Australia

- Raw Materials For Refractory in Djibouti

- Ceramic Fiber Products in Russia

- Monolithic Refractories in Tonga

- Raw Materials For Refractory in Colombia