All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

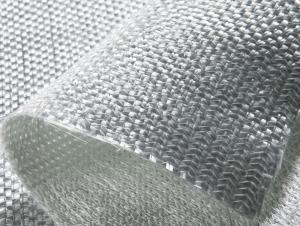

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

What are the different types of fiberglass matting for insulation?

There are several types of fiberglass matting used for insulation, including batts, rolls, and loose-fill. Batts are pre-cut sheets of fiberglass that are typically used for insulating walls and ceilings. Rolls are similar to batts but are continuous sheets that can be easily rolled out for larger areas. Loose-fill fiberglass is a loose, fluffy material that can be blown or poured into hard-to-reach spaces for insulation. Each type has its own advantages and is suitable for different insulation needs.

What are the maintenance requirements for fiberglass products?

The maintenance requirements for fiberglass products include regular cleaning with mild soap and water, avoiding abrasive cleaners or tools that could scratch the surface, inspecting for any cracks or damage periodically, and applying a protective wax or sealant to keep the fiberglass looking its best.

What is the difference between woven and non-woven fiberglass fabrics?

Woven fiberglass fabrics are made by weaving fibers together in a specific pattern, resulting in a strong and structured fabric. Non-woven fiberglass fabrics, on the other hand, are made by bonding fibers together using heat, chemicals, or mechanical processes, which creates a fabric without a distinct weave pattern. This makes non-woven fabrics more flexible and easier to shape, but they may not be as strong as woven fabrics.

Can fiberglass be used for manufacturing storage tanks?

Yes, fiberglass can be used for manufacturing storage tanks. Fiberglass is a versatile and durable material that offers several advantages such as corrosion resistance, lightweight construction, and high strength-to-weight ratio, making it suitable for storing various liquids and chemicals. Additionally, it is easy to fabricate and maintain, making it a popular choice in industries that require storage tanks.

Can fiberglass be made graffiti-resistant?

Yes, fiberglass can be made graffiti-resistant through the application of special coatings or finishes that create a protective barrier, making it easier to remove graffiti without damaging the surface.

Wholesale Fiberglass Supply from supplier in Namibia

With our comprehensive range of Fiberglass Supply products and services in Namibia, you can trust us to meet all your needs. Our top-quality products, competitive pricing, and unparalleled technical support make us the go-to supplier in the market.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to provide a seamless and hassle-free procurement process for all your Fiberglass Supply needs in Namibia.

Our wide product portfolio ensures that you have access to a variety of Fiberglass Supply products tailored to your specific requirements. Our team of experts is dedicated to providing valuable insights and guidance based on years of market development in Namibia.

Whether your project is in construction, industrial applications, or any other sector, we have the products you need. Our commitment to quality, reliability, and customer satisfaction sets us apart as the preferred choice for Fiberglass Supply in Namibia.

Experience the convenience and expertise we offer. Contact us today to discuss your Fiberglass Supply needs and let us be your trusted partner in Namibia.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to provide a seamless and hassle-free procurement process for all your Fiberglass Supply needs in Namibia.

Our wide product portfolio ensures that you have access to a variety of Fiberglass Supply products tailored to your specific requirements. Our team of experts is dedicated to providing valuable insights and guidance based on years of market development in Namibia.

Whether your project is in construction, industrial applications, or any other sector, we have the products you need. Our commitment to quality, reliability, and customer satisfaction sets us apart as the preferred choice for Fiberglass Supply in Namibia.

Experience the convenience and expertise we offer. Contact us today to discuss your Fiberglass Supply needs and let us be your trusted partner in Namibia.

Hot Search

- Fiberglass Chopped Strand in Morocco

- Fiberglass Mesh Cloth in Lesotho

- Composite Pipes in Sri Lanka

- FRP Pultrusion Profiles in Fiji

- Fiberglass Mat Tissue in Botswana

- Fiberglass Fabrics in Georgia

- Fiberglass Mesh in Malaysia

- Composite Tank in Cambodia

- Fiberglass Mesh tape in Netherlands

- Polymer in Moldova