All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

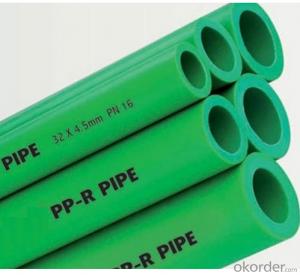

What are the different material options for plastic tubes?

Some of the different material options for plastic tubes include PVC (polyvinyl chloride), HDPE (high-density polyethylene), LDPE (low-density polyethylene), PP (polypropylene), and PET (polyethylene terephthalate). Each material has its own unique properties and is suitable for different applications. PVC is commonly used for plumbing and electrical applications due to its durability and chemical resistance. HDPE and LDPE are flexible and commonly used for packaging and irrigation systems. PP is known for its high heat resistance and is often used for medical and food-grade applications. PET is a clear and lightweight material commonly used for beverage bottles and food packaging.

Are plastic tubes suitable for creating air ventilation systems?

Yes, plastic tubes are suitable for creating air ventilation systems. They are lightweight, durable, and resistant to corrosion, making them an ideal choice for transporting and distributing air in ventilation systems. Additionally, plastic tubes offer flexibility in design and installation, allowing for easy customization and modification to meet specific requirements.

How are plastic tubes made?

Plastic tubes are typically made through a process called extrusion. In this process, plastic pellets or granules are melted and forced through a die to form a continuous tube shape. The tube is then cooled and cut to the desired length.

Are plastic tubes resistant to bacteria or mold growth?

Yes, plastic tubes are generally resistant to bacteria or mold growth due to their non-porous surface and chemical composition. This makes them a suitable choice for applications where hygiene and cleanliness are important, such as in medical or food industries. However, it is important to note that the resistance may vary depending on the specific type of plastic used and the conditions in which the tubes are exposed.

Can plastic tubes be used for pneumatic systems?

Yes, plastic tubes can be used for pneumatic systems. Plastic tubes are commonly used in pneumatic systems due to their lightweight, flexible, and corrosion-resistant properties. They offer good durability, high chemical resistance, and can handle moderate pressure levels. However, the specific type of plastic and tube dimensions should be chosen based on the specific application requirements and operating conditions of the pneumatic system.

Wholesale Plastic Tubes from supplier in Malta

Whether you are looking for Plastic Tubes for plumbing, electrical, or industrial applications, we have a wide range of products to meet your needs. Our team of experts is dedicated to assisting you with product selection, technical specifications, and pricing. We understand the importance of timely delivery and offer efficient logistics solutions to ensure that your orders reach you on time.

In addition to our product offerings, we also provide after-sales support, including troubleshooting and maintenance services. Our commitment to customer satisfaction is evident in our long-standing relationships with clients in various industries.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to leverage global supply chains, access the latest industry trends, and offer competitive pricing for our Plastic Tubes products.

Whether you are a contractor, engineer, or distributor, we are here to provide you with the best Plastic Tubes solutions in Malta. Contact us today to discuss your requirements and experience the quality and reliability of our products and services.

In addition to our product offerings, we also provide after-sales support, including troubleshooting and maintenance services. Our commitment to customer satisfaction is evident in our long-standing relationships with clients in various industries.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to leverage global supply chains, access the latest industry trends, and offer competitive pricing for our Plastic Tubes products.

Whether you are a contractor, engineer, or distributor, we are here to provide you with the best Plastic Tubes solutions in Malta. Contact us today to discuss your requirements and experience the quality and reliability of our products and services.

Hot Search

- Plastic Pipe Fittings in Rwanda

- Plastic Tubes in Slovakia

- Plastic Sheets in Namibia

- Agricultural Plastic Products in Mauritius

- Plastic Nets in Kuwait

- Agricultural Plastic Products in Tanzania

- Plastic Pipe Fittings in Ghana

- Plastic Pipe Fittings in Serbia

- Plastic Tubes in Armenia

- Plastic Nets in Tonga