All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the thermal expansion coefficient of aluminum sheets affect their performance in different applications?

The thermal expansion coefficient of aluminum sheets affects their performance in different applications by determining how much the sheets will expand or contract with changes in temperature. This can impact the dimensional stability, structural integrity, and overall functionality of the aluminum sheets in various environments. For example, in applications where precise dimensions are crucial, such as aerospace or automotive industries, a high thermal expansion coefficient of aluminum may lead to dimensional changes that could affect the performance or fit of components. On the other hand, in applications where thermal conductivity or heat dissipation is important, such as in heat sinks or electronic devices, a higher thermal expansion coefficient can help ensure better thermal contact and efficient heat transfer. Therefore, understanding and considering the thermal expansion coefficient of aluminum sheets is essential in selecting the appropriate material for specific applications to achieve optimal performance.

What is the difference between roll-forming and brake-forming aluminum sheets in metalworking processes?

Roll-forming and brake-forming are two different metalworking processes used to shape aluminum sheets.

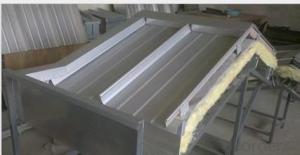

Roll-forming involves passing a continuous strip of aluminum through a series of rollers, which gradually bend and shape the material into the desired form. This process is typically used for long, continuous shapes, such as roof panels or metal siding. Roll-forming offers high production rates and consistent dimensional accuracy.

On the other hand, brake-forming, also known as press-brake forming, involves clamping the aluminum sheet between a matching set of dies in a hydraulic or mechanical press. The press applies force to the sheet, causing it to bend and form the desired shape. Brake-forming is commonly used for smaller, more complex parts, such as brackets or enclosures. It allows for greater flexibility in terms of shapes and sizes.

In summary, the main difference between roll-forming and brake-forming aluminum sheets lies in the nature of the process. Roll-forming is continuous and suited for long, linear shapes, while brake-forming is more versatile and suitable for smaller, intricate parts.

How are aluminum sheets protected against galvanic corrosion?

Aluminum sheets are protected against galvanic corrosion through various methods, such as applying protective coatings, using corrosion-resistant alloys, and employing sacrificial anodes. These measures create a barrier between the aluminum and other metals or environments that could cause galvanic corrosion, ensuring the sheets remain resistant to this type of corrosion.

Wholesale Aluminum Sheets from supplier in Malta

Whether you are looking for Aluminum Sheets for construction, automotive, aerospace, or any other industry, we have the capabilities to meet your specific requirements. Our team of experts is dedicated to delivering the highest quality products and services, ensuring that you receive the best value for your investment.

In addition to supplying Aluminum Sheets, we also offer customized solutions, including cutting, bending, and fabrication services. This allows us to tailor the products to meet your unique project needs, saving you time and resources.

As a subsidiary of CNBM, a global leader in the aluminum industry, we have access to a vast network of suppliers and manufacturers, ensuring that we can source the highest quality materials at competitive prices. Our strong partnerships and efficient supply chain management enable us to deliver Aluminum Sheets to your doorstep in a timely manner.

We understand the importance of technical support and guidance throughout the procurement process. Our team of experts is readily available to provide you with technical advice, product recommendations, and assistance with any queries you may have.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients, based on trust, reliability, and exceptional service. Whether you are a small business or a large corporation, we are committed to meeting your Aluminum Sheets needs in Malta.

Contact us today for sales, quotes, and technical support for Aluminum Sheets in Malta. Let us be your trusted partner for all your aluminum requirements.

In addition to supplying Aluminum Sheets, we also offer customized solutions, including cutting, bending, and fabrication services. This allows us to tailor the products to meet your unique project needs, saving you time and resources.

As a subsidiary of CNBM, a global leader in the aluminum industry, we have access to a vast network of suppliers and manufacturers, ensuring that we can source the highest quality materials at competitive prices. Our strong partnerships and efficient supply chain management enable us to deliver Aluminum Sheets to your doorstep in a timely manner.

We understand the importance of technical support and guidance throughout the procurement process. Our team of experts is readily available to provide you with technical advice, product recommendations, and assistance with any queries you may have.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients, based on trust, reliability, and exceptional service. Whether you are a small business or a large corporation, we are committed to meeting your Aluminum Sheets needs in Malta.

Contact us today for sales, quotes, and technical support for Aluminum Sheets in Malta. Let us be your trusted partner for all your aluminum requirements.