All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

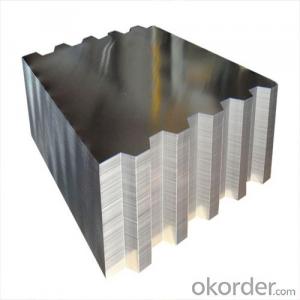

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the composition of the tin coating on electrolytic tinplate coil?

The composition of the tin coating on electrolytic tinplate coil typically consists of a layer of pure tin, which is applied through an electroplating process.

What are the safety precautions when handling electrolytic tinplate coil?

When handling electrolytic tinplate coil, it is important to follow certain safety precautions. Firstly, it is crucial to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a mask to protect against any potential hazards. Additionally, ensure that the work area is well-ventilated to minimize the risk of inhaling any fumes or dust particles. Handling the coil with care, avoiding sharp edges and ensuring proper lifting techniques, can prevent injuries. It is also important to store and handle the coil in a secure and stable manner to prevent accidents or damage. Regular training and awareness regarding the potential hazards associated with electrolytic tinplate coil handling should be provided to employees to ensure their safety.

How does the tin coating on electrolytic tinplate coil affect its resistance to chemical corrosion?

The tin coating on electrolytic tinplate coil greatly enhances its resistance to chemical corrosion. Tin is highly resistant to acidic substances and forms a protective layer on the surface of the tinplate, preventing direct contact of the steel substrate with corrosive agents. This barrier effectively reduces the likelihood of chemical reactions with the metal, thereby significantly increasing the coil's resistance to chemical corrosion.

Can electrolytic tinplate coil be used in the production of metal caps for bottles?

Yes, electrolytic tinplate coils can be used in the production of metal caps for bottles. The tin coating on the tinplate provides corrosion resistance and enhances the durability of the metal caps, making them suitable for use in bottling applications.

Wholesale Electrolytic Tinplate Coil from supplier in Lesotho

Whether you are looking for Electrolytic Tinplate Coil products for packaging, canning, or any other application, we have you covered. Our team of experts will work closely with you to understand your specific needs and provide tailored solutions. We also offer competitive pricing and flexible payment terms to ensure that you get the best value for your money.

In addition to our sales services, we also provide detailed quotations that include all relevant information such as product specifications, prices, and delivery details. This allows you to make informed decisions and plan your procurement effectively.

Furthermore, our technical support team is always ready to assist you with any questions or concerns you may have. They have deep knowledge and experience in the field of Electrolytic Tinplate Coil and can provide guidance on product selection, usage, and troubleshooting.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer efficient and convenient procurement services to our customers in Lesotho. Our strong relationship with reputable manufacturers ensures that we can provide you with high-quality products that meet international standards.

We understand the unique challenges and requirements of the market in Lesotho. Our extensive market experience allows us to offer valuable insights and expertise to enhance the success of your projects. Whether it is understanding local regulations, market trends, or customer preferences, we have the knowledge to support your business goals.

In summary, when it comes to Electrolytic Tinplate Coil products in Lesotho, we are your trusted partner. With our comprehensive range of services, competitive pricing, technical support, and market expertise, we aim to provide you with a seamless procurement experience. Contact us today to discuss your requirements and let us help you succeed.

In addition to our sales services, we also provide detailed quotations that include all relevant information such as product specifications, prices, and delivery details. This allows you to make informed decisions and plan your procurement effectively.

Furthermore, our technical support team is always ready to assist you with any questions or concerns you may have. They have deep knowledge and experience in the field of Electrolytic Tinplate Coil and can provide guidance on product selection, usage, and troubleshooting.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer efficient and convenient procurement services to our customers in Lesotho. Our strong relationship with reputable manufacturers ensures that we can provide you with high-quality products that meet international standards.

We understand the unique challenges and requirements of the market in Lesotho. Our extensive market experience allows us to offer valuable insights and expertise to enhance the success of your projects. Whether it is understanding local regulations, market trends, or customer preferences, we have the knowledge to support your business goals.

In summary, when it comes to Electrolytic Tinplate Coil products in Lesotho, we are your trusted partner. With our comprehensive range of services, competitive pricing, technical support, and market expertise, we aim to provide you with a seamless procurement experience. Contact us today to discuss your requirements and let us help you succeed.