All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

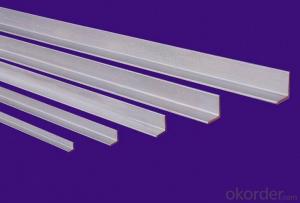

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the applications of special steel in the development of advanced robotics and automation equipment?

Special steel is widely used in the development of advanced robotics and automation equipment due to its exceptional properties. It offers high strength, durability, and corrosion resistance, enabling the construction of robust and long-lasting components. Special steel's excellent machinability and ability to withstand extreme temperatures make it ideal for manufacturing precision parts, gears, and bearings in robotics and automation equipment. Furthermore, its magnetic properties contribute to the development of efficient motors and actuators. Overall, special steel plays a vital role in enhancing the performance, reliability, and efficiency of advanced robotics and automation systems.

Describe the use of steel in the aerospace industry for aircraft components.

Steel is commonly used in the aerospace industry for various aircraft components due to its exceptional strength, durability, and high-temperature resistance. It is utilized in the manufacture of structural parts, such as landing gear, engine mounts, and wing spars, where its strength-to-weight ratio helps ensure the structural integrity and safety of the aircraft. Moreover, steel's ability to withstand extreme conditions, including high temperatures and pressure, makes it suitable for critical components like turbine blades and exhaust systems. Additionally, steel is often employed in fasteners, such as bolts and rivets, as it provides excellent mechanical properties and reliability. Overall, steel's versatile properties make it an essential material for various aircraft components, contributing to the overall performance and safety of aerospace vehicles.

What is the role of steel in the development of sustainable transportation?

Steel plays a critical role in the development of sustainable transportation as it is used extensively in the manufacturing of vehicles, railways, and infrastructure. Its strength, durability, and recyclability make it an ideal material for constructing lightweight yet safe and energy-efficient vehicles. Additionally, steel's widespread availability, low cost, and ability to be recycled at the end of its life cycle contribute to reducing the industry's environmental footprint.

What is the difference between annealing and normalizing in steel production?

Annealing and normalizing are both heat treatment processes used in steel production, but they differ in terms of their purpose and the resulting microstructure of the steel. Annealing involves heating the steel to a high temperature and then slowly cooling it, typically in a furnace. This process aims to relieve internal stresses, improve ductility, and refine the grain structure of the steel. On the other hand, normalizing also involves heating the steel to a high temperature, but it is followed by air cooling instead of slow cooling. Normalizing is primarily used to refine the grain structure of the steel, enhance its mechanical properties, and improve machinability. In summary, while both processes involve heat treatment, annealing focuses on stress relief and grain refinement, while normalizing focuses on grain refinement and mechanical property improvement.

Wholesale Special Steel from supplier in Tanzania

We are a Special Steel supplier serving the Tanzania, mainly engaged in the sale, quotation, and technical support services of various Special Steel products in the Tanzania region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Special Steel procurement services in the Tanzania. Not only do we have a wide range of Special Steel products, but after years of market development in the Tanzania, we can also provide valuable experience for your projects.