All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

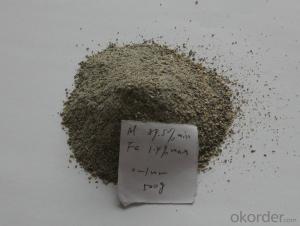

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are refractories rated for abrasion resistance?

Refractories are rated for abrasion resistance through various standardized tests and measurements. These tests evaluate the material's ability to withstand wear and erosion caused by abrasive forces. Common methods include the Taber Abrasion Test, which uses a rotating platform and abrasive wheels to determine the material's durability, and the ASTM C704 test, where the refractory is exposed to a stream of abrasive particles at a specified velocity. The results of these tests determine the refractory's abrasion resistance rating, allowing users to select the most suitable material for their specific application.

What are the different types of chamotte used in refractory applications?

There are several types of chamotte commonly used in refractory applications, including high alumina chamotte, fireclay chamotte, and siliceous chamotte. Each type has specific properties and characteristics that make them suitable for different types of refractory products and applications. High alumina chamotte, for example, has a high alumina content and excellent resistance to high temperatures, making it ideal for use in the linings of furnaces and kilns. Fireclay chamotte, on the other hand, has good thermal shock resistance and is often used in the construction of chimneys and fireboxes. Siliceous chamotte, with its high silica content, is commonly used in the production of glass, ceramics, and other high-temperature materials.

What are the refractory raw materials used in lining glass tanks?

The refractory raw materials commonly used in lining glass tanks include silica sand, alumina, magnesia, and zirconium. These materials have high melting points and can withstand the extreme temperatures inside the tanks, ensuring stability and durability of the lining.

Wholesale Raw Materials For Refractory from supplier in Brunei

With our expertise and experience, we understand the unique requirements of the refractory industry in Brunei. We have established strong relationships with reliable manufacturers and suppliers, enabling us to offer high-quality raw materials at competitive prices.

Our product portfolio includes a wide range of raw materials such as alumina, magnesia, silica, and zirconia, among others. These materials are essential for the production of refractory products used in various industries including steel, cement, glass, and petrochemicals.

When you choose us as your supplier, you can expect excellent customer service from our dedicated team. We are committed to providing prompt responses to your inquiries and offering tailored solutions to meet your specific needs. Our sales team will work closely with you to understand your requirements and provide you with accurate quotations.

We also offer technical support to ensure the success of your projects. Our team of experts can provide guidance on material selection, application techniques, and troubleshooting. We understand the challenges you may face during the production process and are here to assist you in finding the most effective solutions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer a seamless procurement experience, ensuring timely delivery and consistent quality of our products.

At our company, we pride ourselves on delivering reliable and cost-effective solutions for your refractory material needs in Brunei. Contact us today to discuss your requirements and experience the difference of working with a leading supplier in the industry.

Our product portfolio includes a wide range of raw materials such as alumina, magnesia, silica, and zirconia, among others. These materials are essential for the production of refractory products used in various industries including steel, cement, glass, and petrochemicals.

When you choose us as your supplier, you can expect excellent customer service from our dedicated team. We are committed to providing prompt responses to your inquiries and offering tailored solutions to meet your specific needs. Our sales team will work closely with you to understand your requirements and provide you with accurate quotations.

We also offer technical support to ensure the success of your projects. Our team of experts can provide guidance on material selection, application techniques, and troubleshooting. We understand the challenges you may face during the production process and are here to assist you in finding the most effective solutions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer a seamless procurement experience, ensuring timely delivery and consistent quality of our products.

At our company, we pride ourselves on delivering reliable and cost-effective solutions for your refractory material needs in Brunei. Contact us today to discuss your requirements and experience the difference of working with a leading supplier in the industry.

Hot Search

- Monolithic Refractories in Sri Lanka

- Ceramic Fiber Products in Namibia

- Refractory Bricks in Mauritius

- Raw Materials For Refractory in Iceland

- Refractory Bricks in Austria

- Raw Materials For Refractory in Russia

- Monolithic Refractories in Cyprus

- Refractory Bricks in Maldives

- Raw Materials For Refractory in France

- Monolithic Refractories in Andorra