All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

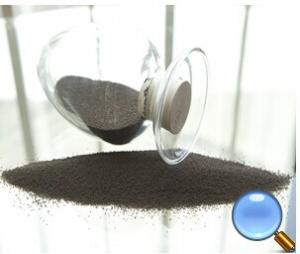

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do monolithic refractories perform in neutral atmospheres?

Monolithic refractories perform exceptionally well in neutral atmospheres due to their high resistance to chemical attack and thermal stability. They are able to maintain their structural integrity and provide superior insulation properties, making them an ideal choice for applications in neutral environments.

How are monolithic refractories resistant to abrasion?

Monolithic refractories are resistant to abrasion due to their unique composition and properties. They are made from a single, homogeneous material, which eliminates weak points and joints that could be susceptible to wear and tear. Additionally, these refractories have high levels of hardness, density, and strength, making them highly resistant to abrasive forces. Their dense structure and chemical composition allow them to withstand the erosive effects of high temperatures, chemical reactions, and mechanical stress, thus providing excellent resistance to abrasion.

How do monolithic refractories handle thermal cycling in calciners?

Monolithic refractories are designed to withstand thermal cycling in calciners due to their excellent thermal shock resistance properties. These refractories can withstand rapid temperature changes without cracking or spalling, which is crucial in calcining processes where the temperature can fluctuate significantly. The monolithic nature of these refractories allows for easy installation and repair, ensuring the integrity of the lining even during thermal cycling. Additionally, monolithic refractories have high thermal conductivity, enabling efficient heat transfer and uniform temperature distribution, further enhancing their ability to handle thermal cycling in calciners.

Can monolithic refractories be used for lining ladle covers and lids in high-pressure applications?

Yes, monolithic refractories can be used for lining ladle covers and lids in high-pressure applications. Monolithic refractories are known for their excellent thermal shock resistance and high strength, which makes them suitable for such demanding environments. Additionally, their ability to conform to complex shapes allows for easy installation and maintenance.

Wholesale Monolithic Refractories from supplier in Andorra

Whether you are in need of Monolithic Refractories for industrial furnaces, boilers, kilns, or any other high-temperature application, our team of experts can guide you in selecting the right product to meet your specific requirements. We work closely with reputable manufacturers to ensure that our products meet the highest quality standards and provide optimal performance.

In addition to supplying Monolithic Refractories, we also offer sales and technical support services. Our dedicated team is available to provide you with detailed product information, answer any technical queries, and assist you in selecting the most suitable refractory solution for your project. We understand the importance of timely and accurate quotations, and we strive to provide competitive pricing without compromising on quality.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we possess the resources and expertise to provide comprehensive procurement services. Our strong network and relationships with manufacturers allow us to offer a wide range of Monolithic Refractories products, ensuring that you have access to the latest technologies and innovations in the industry.

With our years of market development experience in Andorra, we have gained valuable insights and expertise in the local market. We understand the unique challenges and requirements of projects in Andorra and can provide tailored solutions to meet your specific needs. Our team is committed to delivering exceptional customer service and ensuring that your project is a success.

Whether you are a contractor, engineer, or end-user, we are here to support you throughout the entire process, from product selection to delivery and installation. Contact us today to discuss your Monolithic Refractories requirements in Andorra and let us assist you in finding the best solution for your project.

In addition to supplying Monolithic Refractories, we also offer sales and technical support services. Our dedicated team is available to provide you with detailed product information, answer any technical queries, and assist you in selecting the most suitable refractory solution for your project. We understand the importance of timely and accurate quotations, and we strive to provide competitive pricing without compromising on quality.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we possess the resources and expertise to provide comprehensive procurement services. Our strong network and relationships with manufacturers allow us to offer a wide range of Monolithic Refractories products, ensuring that you have access to the latest technologies and innovations in the industry.

With our years of market development experience in Andorra, we have gained valuable insights and expertise in the local market. We understand the unique challenges and requirements of projects in Andorra and can provide tailored solutions to meet your specific needs. Our team is committed to delivering exceptional customer service and ensuring that your project is a success.

Whether you are a contractor, engineer, or end-user, we are here to support you throughout the entire process, from product selection to delivery and installation. Contact us today to discuss your Monolithic Refractories requirements in Andorra and let us assist you in finding the best solution for your project.

Hot Search

- Monolithic Refractories in Morocco

- Ceramic Fiber Products in Montenegro

- Refractory Bricks in Peru

- Raw Materials For Refractory in Brazil

- Monolithic Refractories in Iceland

- Refractory Bricks in Cyprus

- Monolithic Refractories in Yemen

- Refractory Bricks in Haiti

- Raw Materials For Refractory in France

- Ceramic Fiber Products in Libya