All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

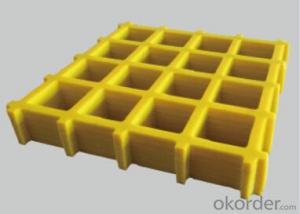

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

Can fiberglass be made impact resistant?

Yes, fiberglass can be made impact resistant by adding reinforcement materials such as carbon fibers or Kevlar, which enhance its strength and durability. This process is commonly used in industries that require impact-resistant materials, such as automotive or aerospace.

How does fiberglass perform in chemical-resistant applications?

Fiberglass performs exceptionally well in chemical-resistant applications. Its inherent properties make it highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and corrosive substances. The composition of fiberglass, with its glass fibers embedded in a resin matrix, provides excellent resistance to chemical attack and degradation. Additionally, fiberglass is non-reactive and does not leach or contaminate the chemicals it comes into contact with, making it a reliable choice for various industrial, laboratory, and manufacturing applications where chemical resistance is crucial.

Can fiberglass supply be used for abrasion resistance?

Yes, fiberglass supply can be used for abrasion resistance. The inherent strength and durability of fiberglass make it a suitable material for applications requiring protection against abrasion.

What are the different types of fiberglass brushes?

There are several different types of fiberglass brushes available, including wire brushes, abrasive brushes, and nylon brushes. Wire brushes are typically used for heavy-duty cleaning and rust removal, while abrasive brushes are used for surface preparation and roughening. Nylon brushes are gentler and are often used for more delicate tasks like polishing or removing debris from sensitive surfaces.

Can fiberglass be used for manufacturing chemical storage tanks?

Yes, fiberglass can be used for manufacturing chemical storage tanks.

Can fiberglass be made non-toxic?

Yes, fiberglass can be made non-toxic by using alternative materials that do not contain harmful substances during the manufacturing process. Additionally, implementing proper safety measures and procedures can also help reduce the risk of toxicity associated with fiberglass.

Wholesale Fiberglass Supply from supplier in Brunei

We understand the unique requirements of the fiberglass industry in Brunei and are committed to delivering high-quality products and services to our clients. Whether you are looking for fiberglass materials for construction, insulation, or manufacturing purposes, we have a wide range of options to meet your specific needs.

Our team of experts is dedicated to providing excellent customer service and technical support throughout your project. We can assist you with product selection, provide detailed quotations, and offer guidance on installation and maintenance.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer competitive prices and ensure a reliable supply chain for our customers.

We have established strong relationships with leading manufacturers and suppliers in the fiberglass industry, enabling us to offer a comprehensive range of products. From fiberglass sheets, panels, and insulation to custom-made fiberglass products, we have the expertise and resources to fulfill your requirements.

At Fiberglass Supply Brunei, we are committed to delivering superior quality products, exceptional service, and timely deliveries. We strive to exceed our customers' expectations and build long-term partnerships based on trust and reliability.

Whether you are a contractor, builder, manufacturer, or individual looking for fiberglass supply solutions in Brunei, we are your one-stop-shop. Contact us today for all your fiberglass needs, and let us be your trusted partner for success.

Our team of experts is dedicated to providing excellent customer service and technical support throughout your project. We can assist you with product selection, provide detailed quotations, and offer guidance on installation and maintenance.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer competitive prices and ensure a reliable supply chain for our customers.

We have established strong relationships with leading manufacturers and suppliers in the fiberglass industry, enabling us to offer a comprehensive range of products. From fiberglass sheets, panels, and insulation to custom-made fiberglass products, we have the expertise and resources to fulfill your requirements.

At Fiberglass Supply Brunei, we are committed to delivering superior quality products, exceptional service, and timely deliveries. We strive to exceed our customers' expectations and build long-term partnerships based on trust and reliability.

Whether you are a contractor, builder, manufacturer, or individual looking for fiberglass supply solutions in Brunei, we are your one-stop-shop. Contact us today for all your fiberglass needs, and let us be your trusted partner for success.

Hot Search

- Fiberglass Chopped Strand in Czech Republic

- Fiberglass Mesh Cloth in Uganda

- Composite Pipes in Chile

- FRP Pultrusion Profiles in Georgia

- Fiberglass Mat Tissue in Venezuela

- Fiberglass Fabrics in Chad

- Fiberglass Mesh in Vietnam

- Composite Tank in Kazakhstan

- Fiberglass Mesh tape in Maldives

- Polymer in Tonga