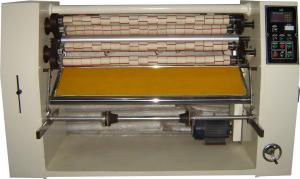

ZJ1300 x 3.0 Slitting line stainless steel cutting machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ⅰ. Technological Capability:

1.1 Raw material: carbon steel strip, fine steel strip, and low alloy steel strip

(σs≤350MPa,b≤500MPa )

1.2 Specification of raw material:

Thickness of steel strip 0.6 - 3.0mm

Width of steel strip 700 - 1300mm

Inner diameter of strip coil 508mm

Max Outer diameter of strip coil 1800mm

Max weight of strip coil 15 tons

1.3 Finished Product

Inner diameter of strip coil 610mm

Outer diameter of strip coil Max1800mm

1.4 Slitting capacity

quantity of srip 4- 15 strips

1.5 Max Line Speed 100m/min

1.6 Input Power: 380Volt, 3 phase, 4 lines, 50Hz.

1.7 Feeding Direction: Left side or right

II Technical flow:

Coil loader → Uncoiler → shovel board device → Feed Flattener → end shear → Centering device→ Slitter→ scrap winder → Accumulator →tension stand→ Recoiler→ Movable support→ Separating Presser → coil unloader

- Q: What is the relationship between metal cutting and numerical control machine tools?

- Metal cutting is more extensive, it can be said that the basic machinery belongs to.

- Q: Causes of retention of mechanical metal chip cutters

- Product cut tumor is unstable in the cutting process, it is time now, later, to a certain height, broken by the workpiece and cutting away and disappear, and then destroy the estate was born again and again. The surface of the workpiece is uneven and the surface roughness decreases. It also causes vibration during cutting and speeds up tool wear.

- Q: What are the differences between metal cutting equipment and metal processing equipment?

- Metal processing equipment is divided into many kinds, metal cutting equipment is one of the metal processing equipment, such as vertical lathe belongs to metal cutting equipment, but also metal processing equipment

- Q: What is the rigidity of process system in metal cutting?

- The stiffness of the process system is equal to the reciprocal of the sum of the rigidity of the machine tool, the fixture, the tool and the workpiece.

- Q: How about the metal cutting parameters?

- According to the cutting force allowed by the process system, including the machine feed system, workpiece rigidity and surface roughness requirements during finishing, determine the feed rate.

- Q: Method of programming for metal cutting machine tools

- According to the general grade: universal machine tools, specialized machine tools, special machine tools.According to the machining accuracy: general precision, precision and high precision

- Q: How is the cutting force calculated in a metal cutting unit?

- The power consumed in the cutting process is called the cutting power Pm (GB Po). The cutting power consumption for Fz and Fx power and Fy direction without displacement, so no power consumption.

- Q: What kinds of typical machine tools are involved in wood processing machinery? What's the difference between metal cutting and metal cutting?

- Woodworking machinery industry development direction has now reached saturation, in recent years, there will be no big turnaround.

- Q: In the process of metal cutting, the process of chip formation consists of several deformation zones

- When plastic metal is cut, the forming process of chip is the deformation process of metal in cutting layer.

- Q: What's the name of the machine that processes cutting tools?

- Machining of high-speed steel cutting tools, the machines used are: general car, milling machine, drilling machine, universal grinding, flat grinding, grinding and so on. Of course, there are heat treatment equipment.

Send your message to us

ZJ1300 x 3.0 Slitting line stainless steel cutting machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords