Zircon Brick ZAS25

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

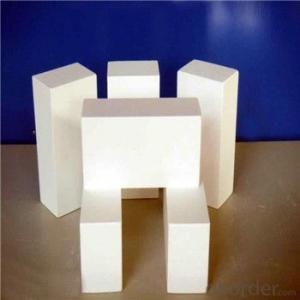

General Information of Zircon Mullite Brick ZAS25

Zircon mullite bricks are using the zircon sand, industrial alumina or super calcined bauxite as the raw materials. The zircon bricks are produced by crushing, grinding, sieving, mixing, pressing, drying, and sintering.

Zirconia gives zircon mullite bricks high temperature mechanical properties.

ZAS20 zircon mullite bricks have 20% content zirconia. CNBM could supply all kinds of shapes and sizes zircon mulliter bricks according to customers’ drawing.

Characteristics of Zircon Mullite Brick ZAS25

Our zircon mullite bricks exhibit the following characteristics:

High refractoriness under load

High tensile strength

Strong resistance to slag

Low thermal expansion coefficient

Typical Application of Zircon Mullite Brick ZAS25:

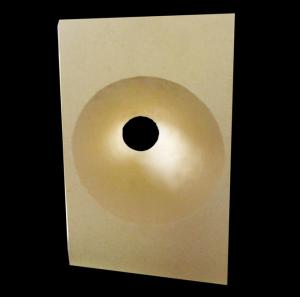

Typical applications of zircon mullite bricks include glass furnace paving, sub-paving and buffer covers. Other applications of zircon bricks include hearth, lower sidewalls and belly-bands in severe service aluminum furnaces and chemical industry.

Technical Data of Zircon Mullite Brick:

Sintered Zircon Mullite Brick---ZAS25 | ||

Physical Properties: |

|

|

Bulk Density | Kg/m3 | 295 |

Cold Crushing Strength | Mpa | 100 |

Apparent Porosity | % | 18 |

Refractories Under Load(0.2Mpa) | ℃ | 1650 |

Chemical Analysis: |

|

|

Fe2O3 | % | 67.0 |

Fe2O3 | % | 0.3 |

ZrO2 | % | 20.0 |

CNBM has success in zircon mullite bricks due to their resistance to high temperature creep and good chemical stability. CNBM also has experience in zircon mullite bricks application and would like to assist you in product selection, system design, and installation techniques.

- Q: What are the ingredients in the binder of the yttrium zirconium brick?

- In the case of adhesive, the normal binder includes the solvent, curing agent, toughening agent, preservative, colorant, defoaming agent and so on.

- Q: What metal materials withstand 1000 degrees high temperature long burning contact with open flame?

- Zirconia brick can withstand 2600 degrees high temperature and good heat insulation performance and long service life

- Q: What's the difference between zirconium and zirconia? What are the fields in which applications?

- Fused zirconia is mainly used for refractory materials, such as zirconia bricks, and used in crystal materials, such as making diamond, and making high-temperature resistant coatings, etc. ~!

- Q: Continuous basalt fiberThere are several questions that we write on paper!Please let me know if you have any information about itHow to choose the heating system for the crucible furnace?The commissioning process of the furnace?

- Glass fiber drawing machine is a kind of mechanical equipment which is made by winding glass fiber at high speed.Wire drawing apparatus for making glass fibresThe drawing parts are mainly crucible, pool furnace, wire drawing machine and temperature control system.

- Q: What is a zirconium drill? Is it valuable?

- Zircon is a silicate mineral. According to its physical and chemical composition, it can be divided into two types: high type and low type, and can be divided into three kinds: high, middle and low. But for gem values, higher zircon values are higher.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 83 Million |

| Main Markets | North America;Eastern Asia;Southeast Asia;Western Europe;Middle East;Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Zircon Brick ZAS25

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords