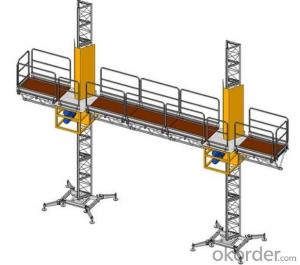

YHX Single Mast Climbing Work Platform

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 40 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Guangdong Yuhuaxing Construction Machinery Manufacture Co., Ltd., established in March 1997, is a private enterprise specializing in R&D, designing, manufacturing, selling and leasing of construction machinery. Headquartered in Baiyun District of Guangzhou, it is the council unit of Decoration and Aerial Work Machinery Branch of China Engineering Machinery Industry Association and a member of Guangdong Standardization Association, mainly producing builder hoist, mast climbing work platform, superdeck loading platform, temporary suspended platform, building maintenance unit etc.

Taking product sale and leasing as the basic market strategy, the company has effectively built “Yuhuaxing” and provided steady cash flow. On one hand, it pushes the independently developed builder hoist, mast climbing work platform, superdeck loading platform, suspended platform and other standardization products to Germany, Sweden, Australia, Malaysia, Singapore, India, etc.; on the other hand, it energetically expands leasing business of builder hoist, superdeck loading platform, suspended platform and other products. Till now, we have established leasing branches in Guangzhou, Beijing, Shanghai and etc. Besides, according to the different requirements of customers, our company actively develops design, production, sale and other business of building maintenance system, steel aluminum shuttering and other non-standard building machinery and metal parts.

High-quality technological management team and first-rate production and detection equipment lay good foundation for the steady development of the company. Its technology and management personnel, including many senior engineers, have college degree or above, and skilled workers mostly have vocational school degree or above. The company also has over 200 general and special production equipment and over 300 measuring instruments for detection. The company passed the certification of ISO9001 Quality Management System in 2002, providing reliable guarantee for the management system and product quality.

Our Yuhuaxing concern requirements of modern city construction and strive to provide products with advanced technology and rational price, furnish good technical support and pre and after-sales service for customers. We hope to create beautiful future with customers.

【Corporate Vision】

Vision:Become an ever-green construction machinery enterprise and maximally meet customers’ requirements

【Core Values】

Quality: High quality, innovation, safety and reliability.

High quality is the basis of the enterprise.

Innovation is the soul of the enterprise.

Safety is reverence to life.

Reliability wins the trust.

Service: Customer focused, customers are existence value of Yuhuaxing people, do what we have promised.

Responsibility: Attentive and responsible, brave to undertake and fully perform individual, company and social responsibility.

【Spirit】

Hard Work:Industry, simplicity, perseverance and hardships are the source power of Yuhuaxing to achieve transnormal and leapfrog development.

Struggle:Concentrated reflection of brave advance, assiduous seeking, brave challenge and enthusiasm and progress of Yuhuaxing people.

Pioneering & Progress::Promote traditions, keep pace with the times, have the courage to innovate and pursue excellence in work

- Q: This question seeks to understand the benefits and drawbacks associated with the use of hydraulic building hoists in construction.

- <p>Hydraulic building hoists offer several advantages, including high lifting capacity, smooth and controlled lifting, and lower maintenance costs due to fewer moving parts. They are also energy-efficient and can be easily integrated into existing systems. However, they have some disadvantages. For instance, they can be more expensive to purchase initially compared to other hoist types. Additionally, they may require more space for installation and can be sensitive to extreme temperatures, which might affect performance. Lastly, hydraulic systems can be prone to leaks and require regular fluid checks and maintenance to prevent system failure.</p>

- Q: Safe use of construction elevator

- 1, seek professional installation. 2, pay attention to safety when using, don't worry, because the elevator is not as fast as the elevator. 3, if there is a broken part, change it quickly, don't delay and feel free

- Q: Is it possible to utilize building hoists in environments with high altitudes?

- <p>Yes, building hoists can be used in high-altitude environments, but their performance may be affected. At high altitudes, reduced air density can lead to decreased efficiency in hoist operations, particularly those powered by combustion engines. It's crucial to select hoists designed for high-altitude use, which may include features such as high-altitude ignition systems and special lubricants. Additionally, regular maintenance and adjustments to the hoist's operation parameters are necessary to ensure safety and optimal performance.</p>

- Q: What measures can be taken to guarantee the smooth and reliable operation of a building hoist during lifting?

- <p>To ensure the smooth and reliable operation of a building hoist, regular maintenance and inspection are crucial. This includes checking the hoist's mechanical components for wear and tear, ensuring the electrical systems are functioning correctly, and verifying that all safety mechanisms are in place and operational. Additionally, proper lubrication of moving parts, adherence to load limits, and operator training on safety protocols are essential. It's also important to use hoists that meet safety standards and to avoid overloading. Regularly updating and upgrading the hoist system can also enhance reliability and safety.</p>

- Q: Is it possible to utilize a building hoist for construction or renovation purposes?

- <p>Yes, a building hoist is commonly used for construction and renovation work. It is designed to lift materials and workers vertically, making it an essential tool for multi-story construction projects. Hoists facilitate the movement of heavy materials like cement, bricks, and steel, as well as personnel, enhancing efficiency and safety on the construction site. They are particularly useful in scenarios where cranes are impractical or unavailable, making them a vital component in the construction and renovation process.</p>

- Q: The maximum allowable deviation of the vertical is the vertical degree when the construction elevator is installed

- The development of the elevator is in a peak state, because most of the manufacturers or individuals to improve the utilization efficiency of space, more options for multistory buildings, which also need a device to convenient up and down by the goods. Due to the common elevator cost is high, bearing capacity is low, not suitable for carrying dozens of tons or hundreds of tons of cargo, so developed a high bearing capacity of hydraulic lift to assist in the production and transportation of goods. The elevators are both safe and super loadable, and convenient for maintenance, making the special industry grow faster.

- Q: This question asks if building hoists can be utilized both indoors and outdoors, and if they can operate under windy or rainy weather conditions.

- <p>Building hoists can be used both indoors and outdoors, but their operation in windy or rainy conditions depends on specific safety guidelines and the hoist's design. Outdoor hoists must be designed to withstand weather conditions and should be equipped with weatherproof covers to protect against rain and wind. In windy conditions, hoists may have operational limits based on wind speed to ensure safety. It's crucial to follow the manufacturer's guidelines and local regulations regarding weather conditions to prevent accidents and ensure the hoist's safe operation.</p>

- Q: What is the purpose of a building hoist and can it be utilized for lifting heavy objects that cannot be manually lifted?

- <p>Yes, building hoists are specifically designed to lift heavy objects that are beyond the capacity of manual lifting. They are essential in construction sites for moving materials such as bricks, cement, and steel beams to various levels of a building. Building hoists are engineered to handle significant weight and ensure the safe and efficient transport of materials, reducing the risk of injury and improving productivity on construction sites.</p>

- Q: Explain the distinctions between electric and electric-motorized building hoists.

- <p>Electric building hoists are powered by electricity and typically use a motor to lift and lower loads. They are designed for vertical transport of materials in construction settings. Electric-motorized hoists, on the other hand, are a specific type of electric hoist that emphasizes the use of an electric motor for operation. The primary difference lies in the level of automation and control. Electric-motorized hoists often have more advanced features like variable speed control and may be integrated into larger systems for automated material handling. Both are efficient, but electric-motorized hoists offer higher precision and control, making them suitable for more complex applications.</p>

- Q: What is the meaning of double straps in the construction elevator?

- With double cage for heavy, namely SCD200/200 series Is the two cages, each cage has a corresponding weight, the weight up and down in the elevator cage rise to energy conservation and reduce the reaction between the up and down, when you imagine front-rear door principle is about the same

Send your message to us

YHX Single Mast Climbing Work Platform

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 40 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords