YFD Series Turned-up Bottle Sterilizer YFD06

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chenyu Packing is a professional company specializing in R & D, manufacturing, technical service and sales of beer and beverage packing machinery.

Among the products, RCGF series, CGF series, DCGF series bottle packing and QGF series barrel packing beverage production lines and QHS series beverage mixer are all designed and made on the base of importing the advanced technology from German, Italy and Japan and its technology keeps the same level as international.

Also the company provides technical consultation, factory planning, installing and adjusting technological train and other services.

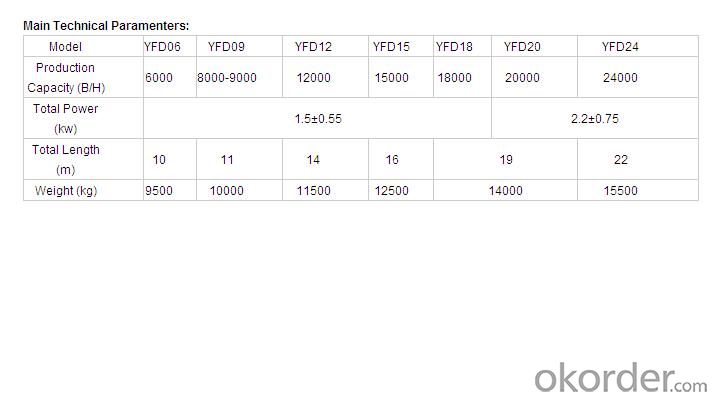

YFD Series Turned-up Bottle Sterilizer:

Usage: This kind of sterilizer is that the angle of bottle overturns to 96°or 110°in the process of transporting bottle ,and then the beverage uses its high temerature(higher than 80°)after filling to give the caps the final sterilization, the sterilizing time can be adjusted in the scope of 30-40sec.as the requirement.Adopting imported stainless steel chain and enduering high temperature plastic chain board.With the excellent features of compacted structure,convenient operation,and saving energy,this kind of machine is the best choice for tea,fruit juice hot filling cap-sterilizing product line.

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q: What are the packing machines?

- Glass glue category of automatic and manual soft packing machine, chemical, I do not know what you are talking about? You can go and have a look.

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: What are the structures of the packaging machinery?

- Is far from a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on. It is well received by Chinese enterprises!

- Q: What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q: What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Different conceptsCompression molding refers to hot forming: mainly for thermoplastic materials (sheet), the use of hot forming machine, Blister molding, I think it should also be considered as a branch of hot stamping, vacuum or high-pressure gas will be used to assist. Hot pressing sheet forming a relatively small depth, relatively simple structure, low precision products, such as packaging materials, plastic pallets, plates in the dishes and so on. There are also forming plate pressing molding (lamination)

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

YFD Series Turned-up Bottle Sterilizer YFD06

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords