Wind Solar Hybrid Controller 1KW-48VPWM Stepless Unload Mode

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

I. PRODUCT INTRODUCTION

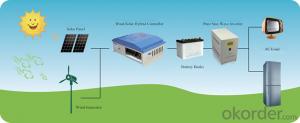

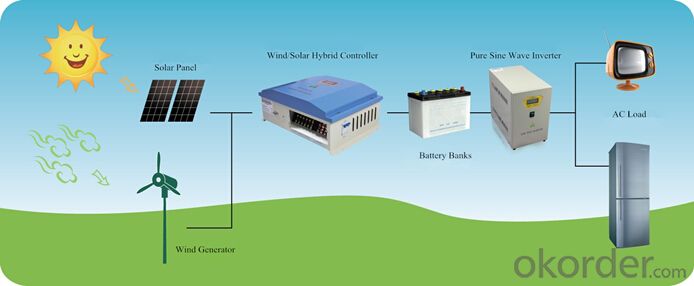

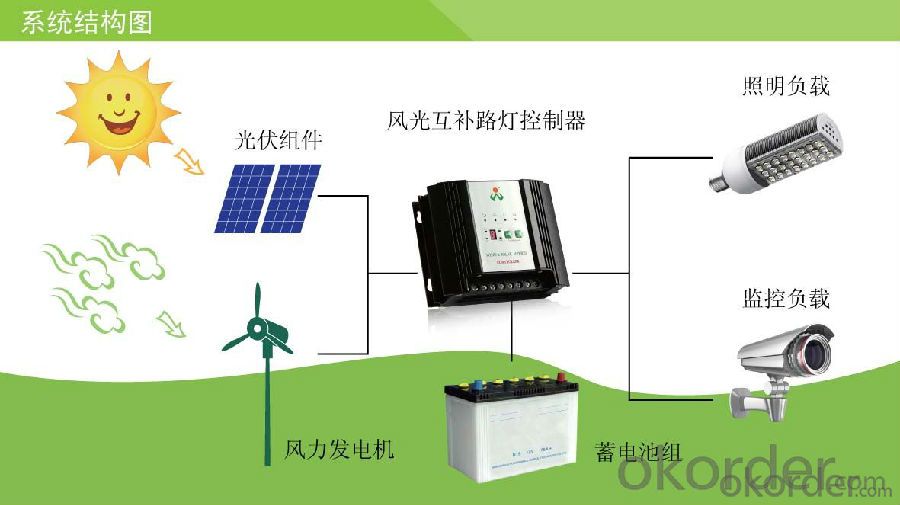

The wind/solar hybrid controller is the control device which can control wind turbine and solar panel at the same time and transform wind and solar energy into electricity then stores to the battery bank.Wind/solar hybrid controller is the most important part in off-grid system, whose performance has much effect on life expectancy and operational stability of the whole system, especially the battery expectancy. Or battery service life will be shortened by over-charge or over-discharge.

II. PERFORMANCE FEATURES

Superior military-grade components to ensure the product stability.

Perfect protection function, thus the system has higher reliability.

Check and set all operation parameters as requirement from LCD display.

Voltage limiting and current-limiting charge mode ensures battery in the best charging status.

PWM stepless unload mode, which burn the excess power into dump load, making the battery charging in best status.

III. APPLICATION AREAS

Stand alone wind/solar hybrid power station; Stand alone domestic household wind/solar hybrid power system.

Mobile communication base stations, expressway and other non-residential regions.

Coastal islands, remote mountainous, border posts for regions shortage of or without electricity.

Government demonstration projects, landscape lighting project.

IV. 1KW TECHNICAL PARAMETERS

Product Model | WWS10-24-N00 | WWS10-48-N00 | WWS10-48-B00 |

Rated Battery Voltage | 24V | 48V | 48V |

Rated Wind Turbine Input Power | 1 kW | 1 kW | 1 kW |

Maximum Wind Turbine Input Power | 1.5 kW | 1.5 kW | 1.5 kW |

Wind Turbine Brake Current | 42 A | 21 A | 21 A |

Rated Solar Input Power | 0.3 kW | 0.3 kW | 0.3 kW |

Floating Charging Voltage | 29V | 58V | 58V |

Dimension (L x W x H) | 442×425×172 mm | Control Box: 205×150×82 mm Dumpload Box: 400×108×50 mm | |

Net Weight | 10 kg | Control Box: 2.2 kg, Dumpload Box: 3.3 kg | |

Display Mode | LCD | ||

Display Mode | Fan | ||

Protection Level | IP20(Indoor) | ||

Quiescent Current | ≤20 mA | ||

Production Functions |

Battery over charge; Battery over discharge; solar reverse charge protection; anti-reverse-connection protection; wind turbine over rotate speed protection; wind turbine over wind speed protection; wind turbine over voltage protection; wind turbine over current protection; manual brake protection; automatically brake protection; lightning protection. | ||

Ambient Temperature | -20~+55℃ | ||

Ambient Humidity | 0~93%,without condensing | ||

Working Altitude | ≤4000m | ||

Data for Micro Current Charge Function | |||

Wind Turbine Start Charge Voltage | 12V | 24V | / |

Dimension(L x W x H) | Control Box: 440×305×170 mm Dumpload Box: 410×270×175 mm | Control Box: 440×305×170 mm Dumpload Box: 300×190×120 mm | / |

Net Weight | Control Box: 7.5 kg, Dumpload Box: 7 kg | Control Box: 7.5 kg, Dumpload Box: 3.5 kg | / |

Data for Low Voltage Charge Function | |||

Wind Turbine Start Charge Voltage | 4V | 8V | / |

Input Admittance Value | 10/15 | 10/60 | / |

Dimension(L x W x H) | Control Box: 440×305×170 mm Dumpload Box: 410×270×175 mm | Control Box: 440×305×170 mm Dumpload Box: 300×190×120 mm | / |

Net Weight | Control Box: 7.5 kg, Dumpload Box: 7 kg | Control Box: 7.5 kg, Dumpload Box: 3.5 kg | / |

In order to serve our customers better. Our company can adjust parameters configuration according to customer’s requirement. | |||

- Q: Can a solar controller be used with a solar-powered recycling bin?

- Yes, a solar controller can be used with a solar-powered recycling bin. A solar controller regulates the flow of energy from the solar panels to the recycling bin's battery, ensuring proper charging and preventing overcharging. It helps optimize the performance and efficiency of the solar-powered recycling bin by managing the power input and output.

- Q: Can a solar controller be used with solar-powered electric vehicle chargers?

- Solar-powered electric vehicle chargers can indeed utilize a solar controller. Acting as a regulating device, a solar controller manages the electricity flow from solar panels to charging systems or batteries. Its primary objective is to ensure the charging efficiency remains high while safeguarding the battery against detrimental overcharging or any potential damage. Specifically concerning solar-powered electric vehicle chargers, a solar controller serves to govern the charging procedure and optimize the utilization of solar energy. It achieves this by controlling the charging speed and preserving the battery's overall health. With the aid of a solar controller, the charging system effectively harnesses solar power, providing a dependable and sustainable solution for electric vehicle charging.

- Q: How long do solar controllers typically last?

- Solar controllers typically last around 10 to 15 years, depending on the quality of the controller and how well it is maintained.

- Q: Can a solar controller be used with a solar-powered hotel or resort?

- Yes, a solar controller can be used with a solar-powered hotel or resort. A solar controller helps regulate and optimize the charging and discharging of batteries in a solar power system. It ensures that the solar panels are generating electricity efficiently and that the batteries are properly charged and protected. In a solar-powered hotel or resort, a solar controller would be essential to manage the energy flow and maximize the utilization of solar power for various applications such as lighting, heating, cooling, and other electrical equipment.

- Q: Can a solar controller be used with a solar-powered manufacturing plant?

- Yes, a solar controller can be used with a solar-powered manufacturing plant. A solar controller helps regulate and optimize the charging of batteries in a solar power system. In a solar-powered manufacturing plant, the solar controller can efficiently manage the flow of energy from the solar panels to the batteries, ensuring a stable and reliable power supply for the plant's operations.

- Q: Can a solar controller be used with solar-powered ventilation systems?

- Yes, a solar controller can be used with solar-powered ventilation systems. A solar controller regulates the flow of electricity from the solar panels to the ventilation system, ensuring efficient operation and preventing overcharging or undercharging of the batteries. It helps optimize the performance of the solar-powered ventilation system by managing the voltage and current levels, providing a safe and reliable power supply.

- Q: Can a solar controller be used with a solar-powered geothermal system?

- No, a solar controller cannot be used with a solar-powered geothermal system. A solar controller is designed to regulate and control the energy generated by solar panels, while a geothermal system uses heat from underground to generate energy. These two systems operate on different principles and require different control mechanisms.

- Q: Does a solar controller have a built-in timer function?

- Yes, a solar controller typically has a built-in timer function. This feature allows users to set specific time intervals or schedules for when the solar system should be activated or deactivated. The timer function is especially useful in applications where energy consumption needs to be regulated or when the solar system needs to operate during specific hours of the day. By utilizing the built-in timer function, users can maximize the efficiency and effectiveness of their solar power system.

- Q: Can a solar controller be used with solar-powered indoor office buildings?

- Yes, a solar controller can be used with solar-powered indoor office buildings. A solar controller is an essential component of a solar power system as it helps regulate and optimize the charging and discharging of batteries and ensures the efficient utilization of solar energy. In the case of solar-powered indoor office buildings, the solar controller would play a crucial role in managing the flow of solar power from the solar panels to the batteries, and then to power the electrical equipment and lighting within the building. It would also help monitor and control the charging and discharging rates to maintain the batteries' health and longevity. Therefore, a solar controller is an integral part of the system that enables the efficient operation of solar-powered indoor office buildings.

- Q: Is a solar controller necessary for all solar panel installations?

- No, a solar controller is not necessary for all solar panel installations. It depends on the type of solar panel system being used. Solar controllers are typically used in systems that include batteries to store excess energy generated by the solar panels. If the system is grid-tied and does not include batteries, a solar controller may not be necessary.

Send your message to us

Wind Solar Hybrid Controller 1KW-48VPWM Stepless Unload Mode

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords