Welding Electrodes AWSE6013 2.5mm Rutile Mild Steel Welding Electrodes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Welding Electrodes AWSE6013:

Introduction:AWS E6013 welding electrode is a kind of carbon steel electrode with high titania type coating AC/DCall-position welding.It has excellent weldability,goodoperating performance,easy reignition,stable arc and beautiful appearance of weld.

USES:For weldinglow-carbon light structuresorlightsteel sheet, machinery,especially suitable for welding on thin plates and cosmetic welding which requires the weld beads to bebeautiful and glossy.

2.Specification & Package of Welding Electrodes AWSE6013:

2.5mmX300mm 2.5kg/box,8boxes to one carton=20kgs

3.2mmX350mm 5.0kg/box,4boxes to one carton=20kgs

4.0mmX400mm5.0kg/box,4boxes to one carton=20kgs

5.0mmX400mm5.0kg/box,4boxes to one carton=20kgs

(Special specifications and packing are available according to customers' requirement.)

3.Chemical Composition of Deposited Metal(%)

Chemical Composition | C | Mn | Si | S | P |

Guarantee Value | ≤0.12 | 0.3~0.6 | ≤0.35 | ≤0.035 | ≤0.040 |

Electrode diameter(mm) | Φ2.5 | Φ3.2 | Φ4.0 | Φ5.0 |

Welding current(A) | 50~90 | 90~130 | 130~210 | 170~210 |

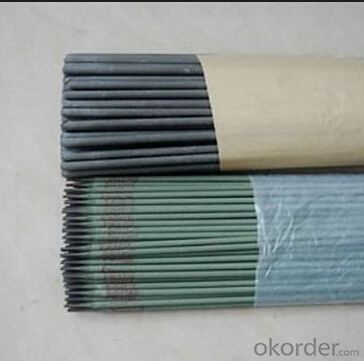

4.Welding Electrodes AWSE6013 image:

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can welding of stainless steel plate and ordinary steel pipe be welded with thj422 welding rod?

- J: stands for structural steel welding rod.42: two figures indicate that the minimum value of tensile strength of deposited metal is 42kgf/mm2 (412MPa), and the minimum value of the yield strength of deposited metal is 34kgf/mm2 (430MPa).2: third digit "2" indicates that the type of coating is titanium calcium type, direct current or AC power supply.According to the national standard GB/T5117 - 95, it is E4303 type ordinary carbon steel welding rod.Two, stainless steel and ordinary steel can be welded, the electrodes used must be the welding of the stainless steel or stainless steel welding rod or wire E31015 E31016.Three, in general, does not recommend the use of stainless steel and carbon steel welding in one place, the use of flange of stainless steel and carbon steel is more appropriate, because long-term exposure, will produce "carburization reaction", the impact characteristics of stainless steel.

- Q: Why can not welding machine welding electrode spark?

- Cause and treatment of welding rod welding spark:1 、 welding current is too small. According to the type and diameter of the electrode used, the welding current shall be explained with reference to the electrode packing box.2 、 the ground wire is not clamped and the ground contact is bad. Check the cable joint firmness with a special ground clamp.3, the surface of the work has greasy dirt, embroidery scale paint, water and other impurities, affecting the electrode conduction. When striking, striking or striking the arc, the instantaneous resistance is greater. It can produce instant sparks, lift the arc, and then rub out the workpiece with an angle grinder, exposing the metallic luster.

- Q: What is the J422 electrode core material

- The J421Z electrode is composed of two parts, core and coating composition. The electrode is coating in metal welding core (coating), uniform centripetal pressure applied to core.The electrode of different types, different cores. The core metal cored electrode, in order to ensure the quality and performance of the weld, there are strict rules on the contents of metal elements in the core, especially for harmful impurities (such as sulfur, phosphorus content, etc.) should be strictly restricted, better than the base metal. The core components directly affect the composition and properties of the weld metal, so the harmful elements in the welding core to as little as possible. For welding of carbon steel and low alloy steel welding core, are mostly made of low carbon steel as the core, and adding manganese, silicon, chromium, nickel and other components (see wire national standard GB1300 - 77). The reason of low carbon is a low carbon steel wire plastic, wire drawing is relatively easy, on the other hand can reduce the CO content of reducing gas, reduce spatter or porosity and increased weld metal solidification temperature, favorable for overhead welding. The addition of other alloy elements mainly guarantees the comprehensive mechanical properties of the weld, and also has some effect on the welding process performance and the removal of impurities.

- Q: What kind of welding rod does aluminum alloy use?

- Specific to see what aluminum alloy, different aluminum alloy may use different welding rod.Turn left and turn right |Turn left and turn right |Turn left and turn right |Aluminum and Aluminum Alloy wire can be used for welding processing spool or longitudinal incision of MIG or TIG, according to its composition can be divided into pure aluminum, aluminum silicon and aluminum magnesium wire into a disc through certain processing methods (coils) or rod (bar) supply, widely used in construction, decoration and equipment, metallurgy and spinning apparatus, pipelines, ships, drilling equipment, train, car, storage tanks and pressure vessels welding processing industry and other industries. Precautions for product use:1, the package after the warranty period you can directly connect the welding, welding without any pretreatment. The product can be stored for more than two years under the condition of packing and sealed. After packing, it can be guaranteed for three months in the normal atmospheric environment;2, the product should be placed on ventilation, dry and with acid and alkali, oil and other local storage medium isolation;3, the product should avoid bumping and damp during transportation, in order to avoid damaging the wire tray and affecting the quality of wire;4, after the wire is removed and packed, it is recommended to apply proper dust cover over the welding wire;5. The wire surface cleaning is recommended before welding;6, welding process of the arc will stimulate your eyes, please pay attention to protection.

- Q: What does the number in the welding rod mean?

- The number in the welding rod represents the specification, model and content of the electrode

- Q: Hand welding electrodes 3.2 and 4 which are more commonly used?

- Electrode core diameter, that is to say, 3.2 of the electrode core is 3.2 millimeters in diameter, and 4 is 4 millimeters in diameter.The diameter of the welding rod is large, and the current should be larger when welding. High current, high efficiency, can be used in relatively thick plate welding. On the contrary, relatively thin plate welding, should choose a smaller diameter welding rod.Electrodes commonly used in three specifications, 3.2, 4, 5. Civil J422 and J506 more commonly used, industrial use of J507, J427 more. But the civilian use of 3.2 diameter more.

- Q: Welding rod for reinforcing cage of bridge pile foundation

- First of all, the electrode strength is greater than the strength of reinforcement, steel cage reinforcement is generally two bar steel bar, with 502 electrodes on it

- Q: How many roots are there in a package of 2.5 electrodes?

- Yibailiuqishi root.

- Q: Can 50Mn2 casting be welded with 507 electrodes?

- 1, the tensile strength of 50Mn2 (b/MPa): 930.2, welding with 507 electrodes is not possible, the intensity difference is too great.3, you can also choose J807 or J 907.4, welding is quick cooling.

- Q: How big is the maximum electrode and how big is the minimum electrode?!

- The electrode current is basically proportional to its diameter.Electrode diameter (mm) 1.6, 2, 2.5, 3.2, 4, 5, 6.Welding current (A) 25~40, 40~65,50~80, 100~130, 160~210, 200~270, 260~500.

Send your message to us

Welding Electrodes AWSE6013 2.5mm Rutile Mild Steel Welding Electrodes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords