Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

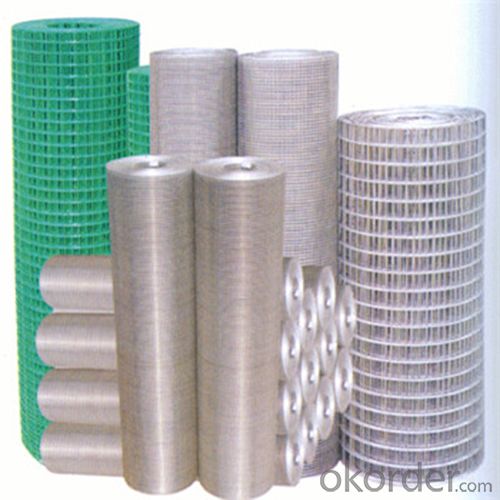

1. Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm Description:

Welded wire mesh is also can be called welded wire mesh sheet or welded wire mesh roll according to its making methods. It is one of the most versatile of all wire mesh.

Widely used in industry, agriculture, building, mine, decoration etc.

Materials: high quality low carbon steel wire, stainless steel wire.

Coating style: Electro Galvanized before welding, Electro Galvanized after welding, Hot dipped galvanized before welding, Hot dipped galvanized after welding, PVC coated.

Zinc coating: 20-250g/m2

2.Main Features of Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm :

• Versatile, High strength, Easy cutting and shearing, Solid construction, Welding point stronger, Easy handling, corrosion- resisting, oxidation-resisting.

3. Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm Images

4.Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm Specification

Specification List of Welded Wire Mesh | |||||||||

Opening | Wire Diameter | ||||||||

In inch | In metric unit(mm) | ||||||||

1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 | |||||||

3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 | |||||||

1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 | |||||||

5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, | |||||||

3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 | |||||||

1" x 1/2" | 254mm x 12.7mm | 16,17,18,19,20,21 | |||||||

1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 | |||||||

1" x 2" | 25.4mm x 50.8mm | 14,15,16 | |||||||

2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 | |||||||

Technical Note: | |||||||||

Specification of galvanized hexagonal wire mesh | |||||||||

Specifications | Wire Diameter | Width | |||||||

Mesh(inch) | Size(mm) | Limit Error | BWG | Metric | BS | Metric | |||

3/8” | 10 | +0.5 | BWG27-23 | 0.40-0.6mm | 1”-6” | 0.1-2m | |||

1/2” | 13 | -1.5 | BWG27-22 | 0.4-0.7mm | 1”-6” | 0.1-2m | |||

5/8” | 16 | +1.0/-2.0 | BWG27-22 | 0.4-0.7mm | 1”-6” | 0.1-2m | |||

3/4” | 20 | +1.0/-2.5 | BWG26-20 | 0.46-0.9mm | 1”-6” | 0.1-2m | |||

1” | 25 | +1.5 | BWG25-19 | 0.5-1.0mm | 1”-6” | 0.1-2m | |||

1-1/4” | 31 | -3.0 | BWG24-18 | 0.56-1.2mm | 1”-6” | 0.2-2m | |||

1-1/2” | 40 | +2.0/-4.0 | BWG23-16 | 0.6-1.65mm | 1”-6” | 0.2-2m | |||

2” | 51 | +2.0/-4.0 | BWG22-14 | 0.7-2.0mm | 1”-6” | 0.2-2m | |||

3” | 76 | +2.0/-4.0 | BWG21-14 | 0.8-2.0mm | 1”-6” | 0.3-2m | |||

4” | 100 | +2.0/-4.0 | BWG20-12 | 0.9-2.8mm | 1”-6” | 0.5-2m | |||

Others we can do as your requirement | |||||||||

Specification of PVC coated hexagonal wire mesh | ||

Opening | Wire Diameter | |

Inch | MM | MM |

1/2” | 13mm | 0.6mm-1.0mm |

3/4” | 20mm | 0.8mm-1.1mm |

1” | 25mm | 0.9mm-1.4mm |

1-1/4” | 30mm | 0.9mm-1.5mm |

1-1/2” | 40mm | 0.9mm-1.5mm |

2” | 50mm | 0.9mm-1.5mm |

Others we can do as your requirement | ||

Mesh/inch | Wire Dia. (mm) | Aperture (mm) |

2 | 1.60 | 11.10 |

4 | 1.20 | 5.15 |

5 | 1.00 | 4.08 |

6 | 0.80 | 3.43 |

8 | 0.60 | 2.57 |

10 | 0.55 | 1.99 |

12 | 0.50 | 1.61 |

14 | 0.45 | 1.36 |

16 | 0.40 | 1.19 |

18 | 0.35 | 1.06 |

20 | 0.30 | 0.97 |

30 | 0.25 | 0.59 |

40 | 0.20 | 0.44 |

50 | 0.16 | 0.35 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm ?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm ?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

10 to 15g Zinc Coating and 35kg Tensile Strength Iron Wire Electro Galvanized Iron Wire

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm

- Q: What is the effect of the wire mesh on the floor

- to prevent the ground crack: barbed wire must be placed on the pipe above the concrete is better (ground crack tile rupture of the reason is not a barbed wire, the second is the ground concrete pouring too thin, concrete pouring to 4-5cm above).

- Q: Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The mesh count refers to the number of holes of 2.54 cm. The unit used to express the mesh in the mesh product specification is hole / cm or line / cm. In countries and regions using imperial units of measurement, the mesh size is expressed in holes / inch or lines / inch.

- Q: Wall tiles how to hang iron wire mesh

- In the wall more nails, and then use the cement bonded wire mesh can solve the above problems;

- Q: Construction in the wall and the beam at the junction of nail wire mesh what role

- To avoid the ground cracks, wire mesh must be placed on the pipe above the concrete center is better.

- Q: How does the "jagged" on the back of the knife cut the barbed wire?

- Knife knife cutting barbed wire as shown: the knife hole slightly and the sheath of the protruding part of a combination on the line (to M86 Saber and AK Army knife, for example)

- Q: What is the barbed wire fence? What is the general specification?

- The appropriate bending, creating a unique aesthetic effect of this product, and the surface can be used in a variety of colors of the dipping treatment, columns and mesh with different colors is pleasing to the eye, while the use of such products with a chassis

- Q: Is the warm tube laid on top of the steel wire or below?

- on the maintenance of the warm tube I told you to see what you use the pipe to decide, if the use of high temperature polyethylene PE-RT material, then you can use a dedicated interface to hot-melt connection to repair, if used Is the coach polyethylene PE-X pipe, then it is difficult to deal with,

- Q: How is the wire mesh made

- materials used generally use high-quality low-carbon steel or stainless steel. In general, it is necessary to produce a number of processes such as plate peeling, pickling, washing,

- Q: Is it possible to protect the radiation around the computer with a wire mesh?

- I have not heard of the wire, the chassis cover is the original radiation ah. Just do not advocate bare metal battle (no chassis or 24 hours cover)

- Q: What is the role of wire in the wire

- The innermost copper wire, is the current carrying effect, used for conductive transmission.

Send your message to us

Welded Wire Mesh Greem PVC Coated Welded Wire Mesh From 0.2 to 7mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords