Waterproof durable healthy 4mm interlock click lvt pvc vinyl floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

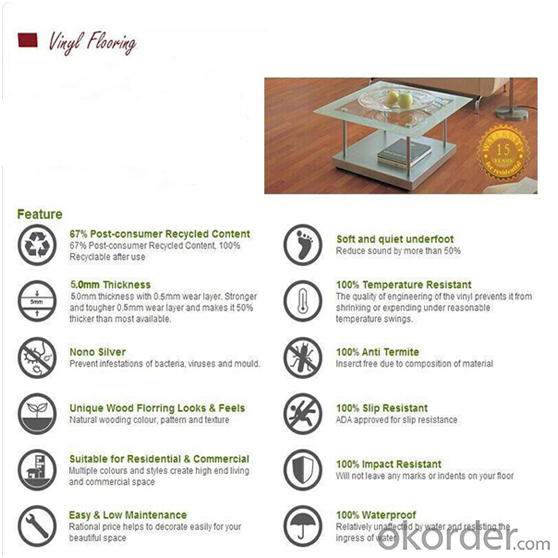

Specification

Specifications

W/L: 0.5mm

Surface: Crystal Texture

Vinyl Plank

UV matt

Size: 1227*157*3.0mm

Why Choose Us

1. 15-Year professional experience in CNBM Flooring.

2. The Fastest Delivery Speed

3. Excellent After-sales Service

Technical Data

Safety Criteria | Standard | Value |

Flammability | EN 13501-1 | Bf1 |

Slip resistance | EN13893 | DS |

Formldehyde Emission | EN717-1 | None |

Color Fastness | ISO 105-BO2 | ≥ 6 |

Castor Wheel Test | EN425 | Pass |

How to install:

Vinyl tiles have always easy to install.but today's no-glue vinyl tile system are even easier.the tiles lock together at the edges to form the surface of the floor,with nothing attaching them to the subfloor, so you can lay them over any solid,flat aurface. Vinyl lock tiles,are formed to look like wood,with a patented locking system.

Instrctions:

1.Remove the floor trim fromt he perimeter of the floor with your hammer and prybar. Don't break it. Set it aside.

2. Lay the first row of this vinyl tiles alongside your starting wall, locking them together at the ends. Put shims between the tiles and the wall, to create a space that will allow for floor expansion. Lay all the full tiles that will fit.

3. Measure the space at the end of the first row of tiles. Use your utility knife to cut a tile to size, running the knife alongside a straight-edge to score it, and then snapping the tile. Lay it with the cut side facing the wall.

4. Lay the next courses of tiles alongside the first building out in courses. Start each course at the opposite end of the room as the previous course, so the ends of the tiles don't line up between courses. Lock the tiles together by their long edges,pushing them in at a downward angle, locking then, then dropping then into space. Cut the ends as necessary.

5. Cover the whole floor. Cut the final course of tiles length-wise, so they fit against the wall with a small gap there(about 1/4 inch).

6. Nail the floor trim back in place, using your hammer and finish nails, to seal off the spaces by the walls. Nail toe trim into the walls and not through the flooring.

- Q: Performance requirements for plastic flooring

- Including the appearance quality, comfortable, water resistance and other properties.1, appearance quality. Including color, pattern, off Ze, flatness and crack, etc.. In general, the distance from the 60cm, the visual can not be uneven, Guan Ze and color unevenness, cracks and other phenomena.

- Q: PVC floor glue what glue plastic floor glue

- Plastic flooring is a broad term. There are a variety of views on the network, it should be said is not very accurate, plastic floor is a very popular in the world today, a new type of light ground decorative materials, also known as "light material".

- Q: Who knows PVC plastic floor tiles?

- This kind of floor is better. An effect close to the wooden floor. More style. Easy to clean with water. Small noise. Easy replacement.

- Q: What is the difference between plastic floor and floor leather? What is the wear resistance of plastic floor? How to distinguish the quality of plastic flooring?

- Floor leather is also called sheet flooring, floor decoration materials is one of the indispensable modern room decoration, 96 years ago, the floor leather is a medium quality and price of products, with a thickness of more than 1.5mm, the wear-resisting layer above 0.1mm, half are using flat glass good or double coating.

- Q: Classroom platform shop plastic floor with no need to do self leveling?

- The floor is made of civil leather, paper and leather, the life of 1 to 2 years, not fireproof material, the price of 5 yuan to 15 yuan of 1 square meters, while the PVC floor is pure engineering material and plastic floor, PVC, life of 6 to 20 years, fire prevention materials,

- Q: With this plastic floor mat bed can not? Will not have any impact on people

- This is used in conjunction with the infant floor, which belongs to (XPS) extruded plate and the like, the density is better. Better than foam board (EPS) slightly better, it is best not to shop on the bed as well......

- Q: What is the difference between hard and soft plastic floor construction

- Generally speaking: the difference between hard PVC and soft PVC is that the hard PVC is very hard, and steel, wood almost, and soft PVC is very soft, and rubber hose. Applications are very broad, the key is to look at the environment and occasions you use.

- Q: Plastic foam on the floor there is no effect of moisture

- In addition to pad plastic film surface is generally relatively thick, so it will not easily deteriorate, generally do not have what problem, whether it is solid wood or composite floor now installed under the floor are used in this material. Mat close to laying on the ground, a waterproof, moisture-proof, protect the floor, increase the elasticity of the film, the ideal thickness is more than 0.22mm, and has the properties of alkali resistant, acid resistant.

- Q: The advantages of plastic floor tile

- Plastic floor than the floor brick advantages are: green, super thin, super wear-resistant, high elasticity and strong impact resistance, strong anti slip 6, 7, 8 fire retardant waterproof, sound-absorbing noise, antibacterial properties, acid and alkali corrosion resistance, easy maintenance etc..

- Q: Such as the title, do not know what is the real wood floor shop? The following is the keel I am looking for the materials and the advantages and disadvantages, we have what opinions and suggestions might as well talk about... 4, keel laid the keel: many materials, the most traditional is also plastic, wood keel, wooden keel and so on Aluminum Alloy 1): on the ground drill, fixed wooden keel, wooden keel on surface leveling the floor with a nail, will start...Home renovation renovation of the old house, the living room plus two bedroom only 41 square meters, which is more suitable for...In addition, the room is small, the shop is too thin and good-looking and consumption of materials, want to shop 455*90*1.8 or 455*120*1.8

- Home is home renovation, so could not live for a long time, suggested the use of wooden keel, more environmentally friendly, but in which you want to add pepper and aniseed and lime mothproof, decadent

Send your message to us

Waterproof durable healthy 4mm interlock click lvt pvc vinyl floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords