Virgin Polypropylene Staple Fiber PP staple fibre

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Virgin polypropylene (PP) staple fibre is a synthetic fibre made from 100% pure, unprocessed polypropylene resin. This type of fibre is known for its consistency in quality, strength, and durability, as it has not been recycled or mixed with other materials.

Main features:

High Purity: Made from virgin polypropylene, ensuring superior quality and performance without any contaminants.

Excellent Strength: Provides high tensile strength, making it durable and suitable for demanding applications.

Lightweight: Like all PP fibers, it is lightweight, contributing to weight reduction in end products.

Chemical Resistance: Highly resistant to chemicals, including acids and alkalis, which makes it ideal for use in harsh environments.

Low Moisture Absorption: Absorbs very little water, making it quick-drying and resistant to mold and mildew growth.

Consistent Quality: The use of virgin material ensures uniformity in fiber properties, resulting in reliable performance across applications.

Application:

Our products can be used in

non-wovens,

automotive interiors,

geo-textiles,

speaker cloth and needle carpet,

spinning wool,

filters,

adsorption materials.

Specifications:

Uses: Non-woven, carpet

Strength: 4.0-4.5CN/dtex.

Specification:3d-10d

Payment : T/T ,L/C

Technical Data Sheet:

3D-10D Polypropylene fiber for fabric Polypropylene monofilament fiber technical | ||

1 | Material | 100% polypropylene |

2 | Length | 38mm 51mm 65mm 76mm 102 |

3 | Density | 0.91g/cm³ |

4 | Denier | 3D-10D |

5 | Tensile Strength | 4.0-4.5CN/dtex |

6 | Elongation at break | <80% |

7 | Melting point | 165C |

8 | Usage | Non-woven, automotive interior, carpet |

9 | Package | About 220kgs~280kgs per bales |

10 | Delivery time | Within 15days after deposit |

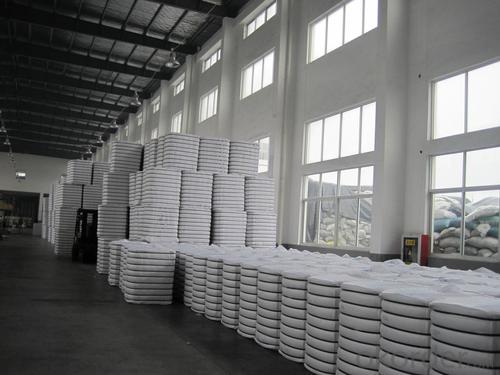

Images:

- Q: What functions can the fiber rotary drum filter play in the sewage treatment process?

- Now, the discharge standard of municipal wastewater treatment plant is upgraded from grade B to A, and SS is upgraded from 20mg/l to 10mg/l, and COD from 60mg/l to 50mg/l (other indexes are abbreviated)

- Q: Do you have two kinds of eyelashes fiber, white and black?

- Usually, this mascara with white fiber has black mascara.1, first use three section clamp method, the eyelash clamp gets warped.2, with black mascara base, first, in order to make eyelashes thicker, two is to make white fiber better sticky above. When you brush, pay attention to the "Z" glyph.3, and then brush white fiber, Z brush shape.4, and finally brush a layer of black can.

- Q: 100% does polyester fiber stretch?

- There are many kinds of polyester fiber: PET, PBT, PTTThe former is commonly referred to as polyester PET (polyethylene terephthalate)The second is an elastic PBT (polybutylene terephthalate)Third flexible and memory functional PTT (poly (ethylene terephthalate))

- Q: Polyester and polyester fabrics are good

- Polyester and polyester fiber and their application in the field of clothing each one has his good points. Polyester fabric refers collectively blended polyester and cotton fabric, with 65% - 67% and 33% - 35% of the polyester cotton blended yarn woven into textiles, commonly known as cotton dacron, polyester cotton has highlighted both polyester and cotton fabric style strengths, in dry and wet conditions and better flexibility and abrasion resistance, stable size, small shrinkage, with tall and straight, not easy to fold, easy washing and drying characteristics of a plain weave, twill, canvas, Oxford spun silk yarn, thread silk, satin and other varieties; in the finishing of special additives such as Teflon three, suitable for the production of clothing, clothing and special occupation. Casual clothing.

- Q: What is a new type of recycled fiber?

- Soybean protein fiber is out of oil after the soybean dregs as raw material, the use of biological engineering technology, the soybean meal ball in protein purification, and through the role of biological enzyme, the purified globulin change spatial structure, then add hydroxy and amino polymer, preparation of protein spinning solution concentration, spinning a wet spinning process. Soybean meal is a by-product of the oil workshop. It is rich in resources in China and belongs to the comprehensive utilization of waste. The resources are inexhaustible. Soybean protein fiber can be called "green fiber" in the new century". Because the outer layer of soybean protein fiber is basically protein, and has good affinity with human skin, and contains many kinds of amino acids required by human body, and has good health care function. Chinese herbal medicine and protein side chain adding quantitative in the spinning process of soybean protein fiber in the bactericidal anti-inflammatory effect by combination of chemical bond, significant efficacy and lasting, avoid functional cotton products finishing method developed products, the effect is difficult to continue the disadvantages. The soybean protein fiber fabric feels soft and smooth, has good moisture absorption and breathability, has silk like luster, crease resistance is superior to silk, and the dimension stability is good.

- Q: What are the benefits of bamboo fiber products?

- No heavy metals, no harmful chemicals, no chemical direct dyeing, no pesticide residues4., completely natural sampling, natural degradation, natural environmental protection, is an international advocate of eco textile supplies5. 、 absorb sweat and reduce static electricity

- Q: Which is better, carbon fiber or glass fiber reinforced plastic?

- Glass fiber reinforced plastics (FRP), also known as GFRP, that is, fiber reinforced plastics, generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastics made from glass fiber or its products are called fiberglass reinforced plastics, or "GRP", and they are distinguished from tempered glass. Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. It is light and hard, non conductive, stable in performance, high in mechanical strength, low in recycling and corrosion resistant. It can be used instead of steel to make machine parts, automobiles, ship shells, etc..

- Q: What is nonwoven fiber?

- Nonwoven fabric production technology originated in the paper and felt. Early nonwoven fabrics were treated with waste cotton or textile waste, and were used as low wadding mats or thermal insulation materials. After 50s, the chemical fiber production technology development greatly, textile fabrics can be improved, acupuncture, tufting, stitching and other technologies have been adopted, natural fiber and chemical fiber nonwoven cloth production increased, use widely. The manufacturing methods of nonwoven fabrics are divided into two categories, dry method and wet method.

- Q: Is not pure cotton will pilling it?

- In fact, cotton fabric is not 100% no pilling, because cotton fabric is divided into several grades, the best cotton is the longest fiber manufacturing refined cotton and lint cotton fabric after treatment, the surface will be a layer of soft hair. Any surface of the wool fabric, after friction, the surface of the wool fibers will be tangled together, forming a pilling phenomenon.

- Q: What are fiber tapes?

- The fiber adhesive tape is made of PET as the base material. It has reinforced polyester fiber yarn and is coated with special pressure sensitive adhesive.

Send your message to us

Virgin Polypropylene Staple Fiber PP staple fibre

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords