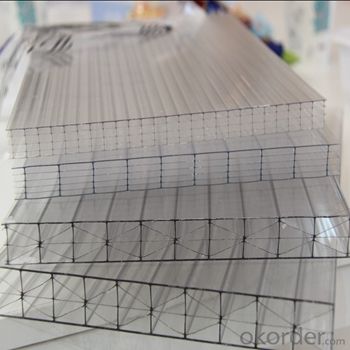

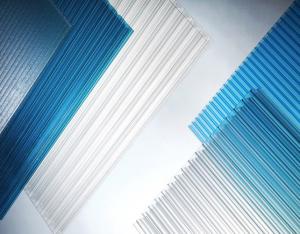

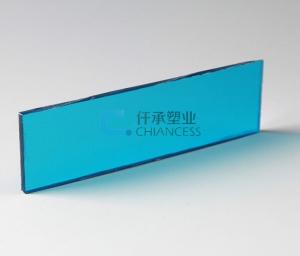

Twin Wall PC Hollow Sheet Flame Resistance Rated Class B1

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 600 m²

- Supply Capability:

- 8888888 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

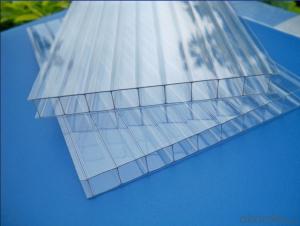

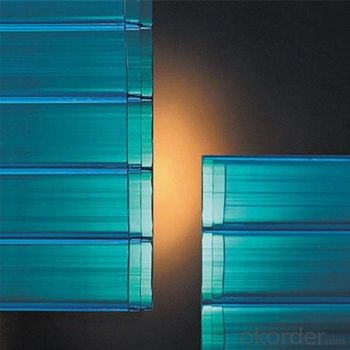

Polycarbonate howllow sheet

1. High impact resistance, unbreakable, long lifespan.

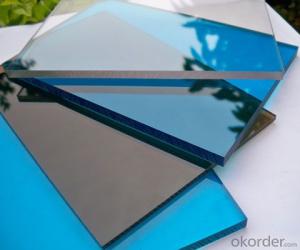

2. High clarity and light transmission, it is different based on colors.

3. Weather ability and wear resistance.

4. Wide service temperature range, not influenced when -40~120 centigrade.

5. Good acoustical insulation.

6. Easy to handle and install for the light weight.

7. Versatile, formable and machinable.

Features:

1) High light transmission: over 82%

2) Excellent impact resistance: 80 times of same thick glass.

3) Weather and UV resistant-properties retained for years. Temperature resistance range is -40°C ~ +120°C, with an ultraviolet coextruded film on the sheet surface. It can prevent the resin fatigue or yellowing caused by the ultraviolet.

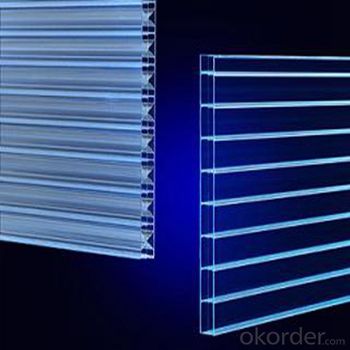

4) Light weight: only 1/12 of the weight of glass of the same thickness. It can be easily cold bent as well as thermal shaping.

5) Flame resistance: High fire performance rating is class B1.

6) Sound and heat insulation: Superb sound insulation for freeway barrier and super thermal insulation save energy.

7) An engineering plastic of excellent integration capability. It has outstanding physical, mechanical, electrical and heat capabilities.

PP Hollow Sheet is made of high density polypropylene. This plastic product is non-toxic, odorless, anti-moisture and it has corrosion resistance, light weight, good appearance and color-rich etc.

It also has the function of anti-bending, anti-aging, high bearing strength, tensile, compression, tear performance. The thickness of this product can be made as 3 ~ 5 mm according to customization requirement. This product is used for various indicator boards, posters, billboards, packaging, cultural and office stationery.

FAQ:

1. Q: Your company can product how many different kinds of Polycarbonate Sheet Sunshine Board?

A: Our company now have following several products: Glittering Polycarbonate Sheet, Multi-wall Structure Polycarbonate Sheet, Greenhouse Polycarbonate Sheet, General Polycarbonate Solid Sheet, Advertising Polycarbonate Sheet, Polycarbonate Embossed Sheet, Polycarbonate Frosted Sheet, Soundproof Polycarbonate Sheet, Greenhouse Polycarbonate Sheet etc.

2. Q: .What will happen in the event of a fire?

A: Fire safety is one of polycarbonate's strong points. Polycarbonate sheeting is flame retardant and do not emit toxic substances, which is why they are so often incorporated in public buildings.

Product Pictures

- Q: Who can tell me, plastic hollow board and PC sun board in the end what is the difference?

- PC sun panels PC has a deliberately anti-UV performance, mobility is not high, high transparency Ordinary plastic plates can be other materials

- Q: What is the difference between a hollow board and a sunboard?

- The material selected for the panel should be FRP, and the selection material for the sun board is PC. The lighting board is fixed with aluminum fastener, and the corrugated board is fixed with a light plate and a self-tapping screw. The position of the lighting plate is generally set in the middle.

- Q: PC sun panels and color steel plate how to bond

- The use of sealant at the junction, with self-tapping screws fixed on the purlins. Transparent sun panels and insulation color plates are two different roofs. The sun panels are mainly made of PC / PET / PMMA / PP. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly. Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate. Color steel plate is divided into veneer, Caigang composite board, floor board and so on. Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs.

- Q: Can the stencils be made in the bathroom?

- PC particle board characteristics 1, the surface of the plate can reflect the direct light on the plate of direct exposure, after this treatment can reduce the sunlight penetration. 2, the surface of the board can increase the surface area, while increasing the heat, can extend the service life of the plate. 3, the surface of the plate per square meter distribution of 15,000-18000 pieces of anti-diamond-type particles, reflection, refraction effect can enhance the blocking capacity.

- Q: PC sun board life years?

- In fact, the warranty period of the sun board is the warranty of the yellowing index, depending on the UV (UV stabilizer) into the number of cases, under normal circumstances, 50μ UV yellowing index warranty for 10 years

- Q: Sunny plate that is a transparent that I want to use the home screen 4mm thickness can be about how much a square

- Generally solid and transparent is the stamina board, do the bath on the screen in general 3mm, 4mm can, the specific price depends on what you need the quality of the

- Q: What is the difference between the PC and the PC board?

- Two products are the same material, but the production process is not the same, the price is generally the same circumstances

- Q: What is the difference between sun panels and lighting panels?

- Thermal expansion The thermal expansion of the lighting material directly affects the ease of construction, construction costs, and the performance of the water after the completion of the project. Therefore, the thermal expansion of the lighting material in the roof of the web plus color plates is the most important factor in design and construction. FRP thermal conductivity of 0.158w / m.k, light rate of 50% - 85%. PC thermal conductivity of 0.166w / m.k, light rate of 85% - 91%.

- Q: Can sunscreen be insulated at night? PC sunshine board insulation performance how?

- PC sun panels are lower than ordinary glass and other plastic thermal conductivity (K value), insulation effect than the same glass 7% -25%, PC sunshine board insulation up to 49%. So that greatly reduce the heat loss, for heating equipment, building, is environmentally friendly materials.

- Q: Lighting board and sunshine board which is good?

- Sunshine board heat insulation effect is good but not weathering a hot one frozen to die because he is a PC. Lighting board lighting good insulation effect is poor, not afraid of acid and alkali, weathering and more useful life.

Send your message to us

Twin Wall PC Hollow Sheet Flame Resistance Rated Class B1

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 600 m²

- Supply Capability:

- 8888888 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords