Tubular Fabric Edge-Cutting Winding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Tubular Fabric Edge-Cutting Winding Machine

Packaging Details: Wooden case/ pallet or as your request.

Delivery Detail: 7-15 Days after confirm the order.

Specifications of Tubular Fabric Edge-Cutting Winding Machine

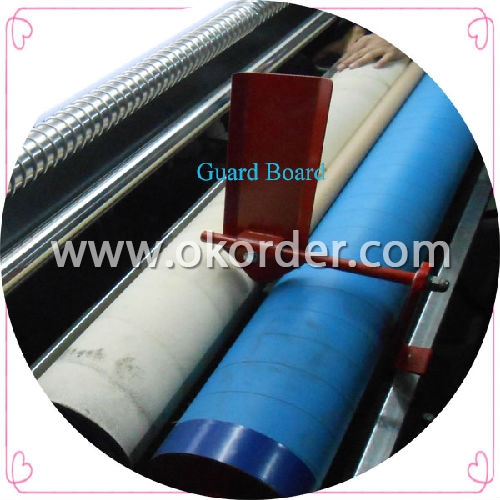

Edge-Cutting Winding Machine

1.Hydraulic edge-aligning system

2.12 years expreience

3.Used tubular knitted fabric

4.CE

Usage of Tubular Fabric Edge-Cutting Winding Machine

Tubular Fabric Edge-Cutting Winding Machine is specially designed to slit, inspect and rewind tubular fabrics and it is suitable for knitting plant.

- Q: What are the characteristics of common clothing fabrics?

- 2, linen, linen, is a marijuana, linen, ramie, jute, sisal, banana and other linen plant fiber made of a fabric. Generally used to make casual wear, work equipment, now more than its production of ordinary summer. Its advantages are high strength, moisture absorption, thermal conductivity, breathability is very good. Its shortcomings are wearing less comfortable, the appearance of more rough, blunt.

- Q: What is the textile fabric according to the organizational structure?

- Knitted fabric, the use of knitting needle yarn or filament into the coil, and then the coil from each other, due to the fabric structure of the coil, the unit length of the amount of stored in the yarn more, so most of the good flexibility.

- Q: What are the characteristics of chemical fiber fabrics?

- D. Vernon characteristics: good strength, moisture, not afraid of mildew, not heat, easy to shrink, easy to wrinkle, texture and durable

- Q: How to distinguish polyester, polyester taffeta, nylon, pongee fabric?

- 2. Nylon - Nylon, also known as Nylon, polyamide fiber. Advantages are high strength, high wear resistance, high chemical resistance and good resistance to deformation, anti-aging. Disadvantage is feel hard. PittEX, CORDURA. General 70D multiples of fabric is nylon, such as 70D, 210D, 420D, 840D, 1680D are nylon material, fabric gloss is relatively bright, feel more slippery

- Q: What is the meaning of mercerizing in dyeing?

- Mercerizing, be sure to use the alkali or steamer to the alkali, or wash to alkali and other methods to fully alkali until the fabric was neutral.

- Q: What is the finishing of cotton fabric?

- Cotton fabric finishing includes both mechanical and chemical aspects. The former are tenter, calendering, electro-optical, embossed and mechanical pre-shrinking finishing

- Q: What are the characteristics of fabric waterproofing agent?

- Under the action of heating and catalyst, the active silicone oil is crosslinked and polycondensed into a durable water repellent film.

- Q: What is the finishing line of textile printing and dyeing?

- Mainly contained in the process: printing: cooked yarn fabric printing, curing, rinsing, ironing finishing;

- Q: What are the common types of garment printing machines?

- A wide range of garment printing machine, more common are: flat screen printing machine, rotary screen printing machine, thermal transfer printing machine, digital printing machines.

- Q: How to identify silk and rayon by hand?

- Silk feel soft, flexible, gently when the sound of silk, there is cool feeling; and rayon feel more rough, not wet cold feeling.

1. Manufacturer Overview

| Location | Changshu, China |

| Year Established | 2008 |

| Annual Output Value | 15Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | Above2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Tubular Fabric Edge-Cutting Winding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches