TPU Film Used for Medical Devices of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Pallet Wrapping

Compacting & Bunding

Shipping

Handling & Protection

Moving & Storage

Garden

Home

ndustrial & Commercial

DIY

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

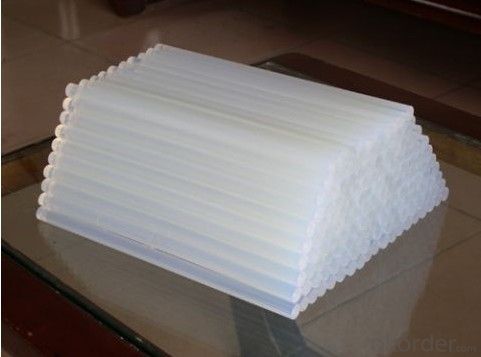

5.Pictures of TPU Film

6.Specification of TPU Film

Model: TF series | Origin:Jiangsu China | Materials:TPU film |

Depth:0.012-1(mm) | width:1-2(mm) | Tensility:OK |

Air permeability: Low penetration | Property instruction: Transparent | |

1)thickness0.012mm~1mm

2)width:1-2 m

3)longth:<(=)1500m< span="">

4)colour:can be coloured as requirements

5)180° Strip Force:0.3N/25mm~3.0 N/25mm

6)viscous force(40,1kg):>(=)24h

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What kind of protective film for desktop LCD monitor?

- By the way, it's better to use a PET LCD monitor to protect the film, which is better than other materials. The protective film about card brand is also good, introduce you, hope to solve your problem.

- Q: Mobile phone screen film stuck on how bubbles ah, how sticky ah?

- To introduce you to a good use of protective screen, as long as you gently put down, you can self adsorption, without any bubbles, dirt, very perfect - Peacock screen - screen protection experts, the first self adsorption glass protection screen! The proprietary technology of self - adsorption, fully transparent and explosion-proof glass has been used to subvert the characteristics of the old screen saver with a new design structure.

- Q: Plastic steel doors and windows on the protective film for a long time, aging how to get rid of it?

- (2) be patient for 24 hours.(3) after wiping with a cloth to dry grease, then the protective film has been separated from the plastic doors and windows.(4) remove the protective film with your hands and then peel off.

- Q: What to do if there are some white dots on the protective film coated on high-light product?

- Please use protecive film of better quality. The foggy white dots may be generated because the glue reacts with the air.

- Q: How can the protective film on the outer layer of the stainless steel thermos cup be removed?

- The protective film on the outer surface of the stainless steel thermos cup can be removed by the following methods:1, with paper towels stained with some alcohol (preferably with industrial alcohol, not to use medical also OK) wipe, and then rub a few stainless steel protective film on the clean.2. Use nail polish. The usage is similar to alcohol acetone. The effect is also good. Washing water does not require quality, good or general, as long as you can wash off all nail polish.

- Q: What kind of printing press is needed to cover decorative protective film?

- During the processing of protective film, film mulching machine must be used in film mulching. And gravure rotary press can be used in printing the protective film.

- Q: There are two screens in the computer screen. One side says "A", and the other is "B". Do you need to paste A first and then paste B? Do you have two at a time? Thank you

- 3., after the good, and then start from the label, tear off the layer (in front of your layer) release film.

- Q: What is the difference between the three-layered anti-static protective film and ordinary film?

- The quality of ordinary three-layered protective film is better than that of ordinary film. But it's just a improved product of ordinary film. The effect doesn't reach the requirement for good film.You can make do with it. There are often bubbles and dark bands on the screen when it's coated on the screen! The surface of real three-layered anti-static protective film is specially processed to make it anti-friction and anti-scratch. The structure of ADPO three-layered anti-static protective film: PET covering layer, PET composite layer and PET release layer. The hardness of the film is pretty high. It's mainly used to protect the screen from scratches left by touching pen. It has outstanding and supreme product features.

Send your message to us

TPU Film Used for Medical Devices of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords