TP8-200A Rotary Packing Machine automatic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Descriptions of TP8-200A Rotary Packing Machine

TP-TGXG-200 Bottle Capping Machine is an automatic capping machine to press and screw lids on bottles. It’s special designed for automatic packing line. Different to traditional intermittent type capping machine, this machine is a continuous capping type. Compared to intermittent capping, this machine is more efficient, pressing more tightly, and do less harm to the lids. Now it’s widely applied in food, pharmaceutical, chemical industries. It consists of two parts: capping part and lid feeding part. It works as following: Bottles coming(can joint with auto packing line)→Convey→Separate bottles in same distance→Lift lids→Put on lids→Screw and press lids→Collect bottles.

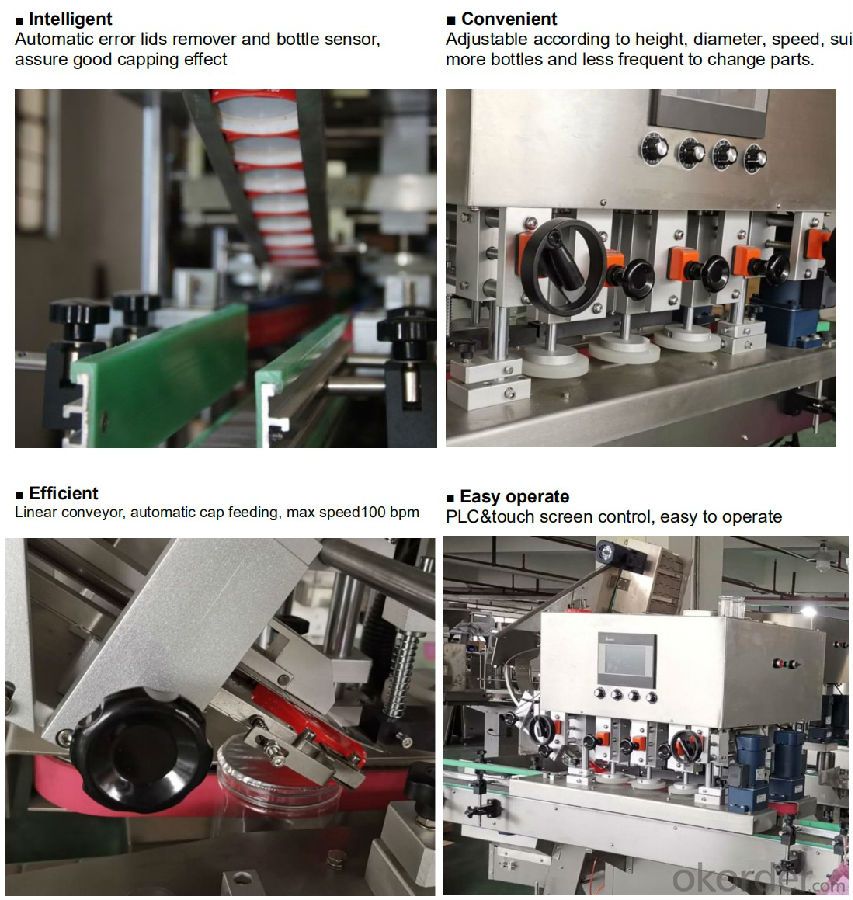

2. Main features

- PLC&touch screen control, easy to operate

- Easy to operate , Speed of conveying belt is adjustable to synchronous with whole system

- Stepped lifting device to feed in lids automatically

- Lid falling part can remove error lids away(by air blowing and weight measuring)

- All the contact parts with bottle and lids are made of material safety for food

- The belt to press the lids is inclined, so it can adjust the lid into the correct place and then pressing

- Machine body is made of SUS 304, meet GMP standard

- Optronic sensor to remove the bottles which are error capped (Option)

- Digital display screen to show the size of different bottle, which will be convenient for changing bottle(Option).

3. Technical parameters

| TP-TGXG-200 Bottle capping machine | |||

| Capacity | 50-120 bottles/min | Dimension | 2100*900*1800mm |

| Bottles diameter | φ22-120mm(customized according to requirement) | Bottles height | 60-280mm(customized according to requirement) |

| Lid size | φ15-120mm | Net weight | 350kg |

| Qualified rate | ≥99% | Power | 1300W |

| Material | Stainless Steel 304 | Voltage | 220V/50-60Hz ( or customized) |

4. Detailed photos

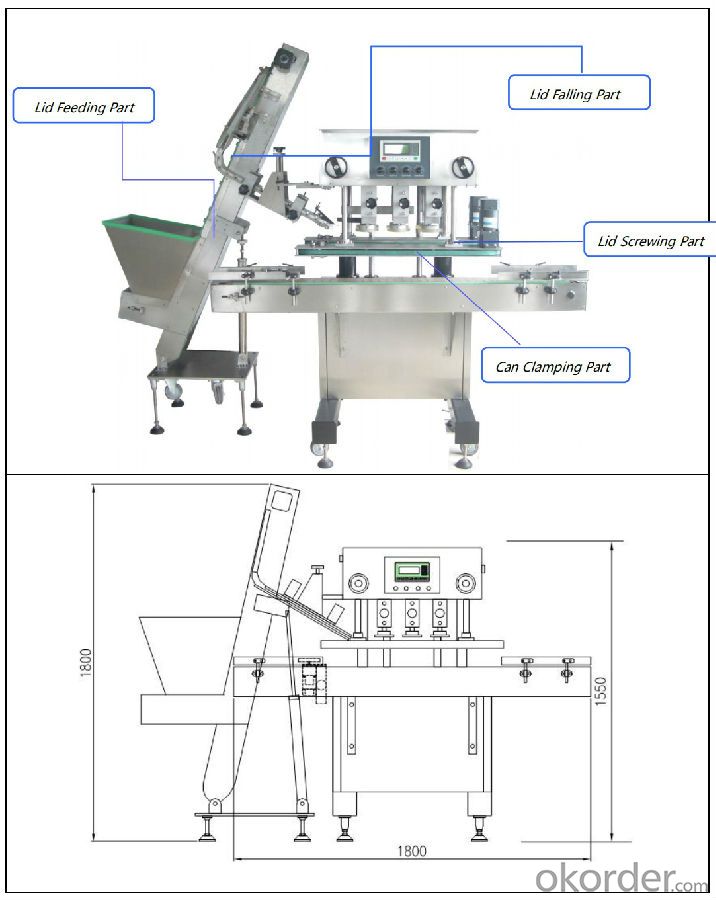

5. Structure & Drawing

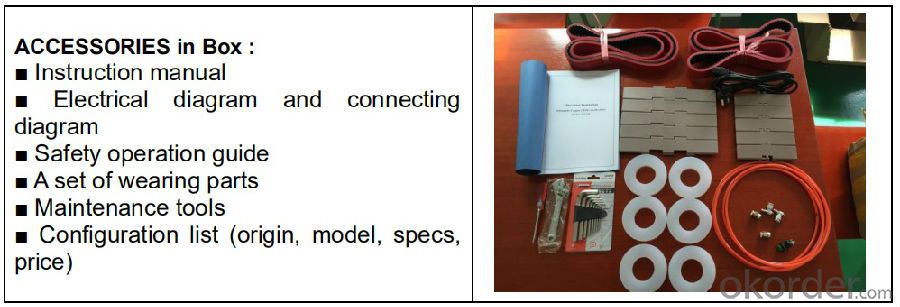

6. Shippment & Packaging

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- 10 bags were randomly extracted from each of them, and the actual quality was measured as follows: (unit G)A: 501500503506504506, 500498497495B: 503504502498499501, 505497502499

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q: What are the main functions of packaging machinery and equipment?

- Sealing and other major operations, and related processes before and after,

- Q: What machine does the packing carton machine have?

- Since its establishment, the company has continued to provide specialized packaging equipment and transportation equipment for domestic first-class enterprises, as well as perfect solutions for automated transportation systems.

- Q: Whether you can press paper plastic molding after PET

- Another hot pressing mould pressing needs, blister sealing machine uses a plastic bakelite mold mold, high frequency plastic welding machine is used Aluminum Alloy mold. The size of the mold needs to be determined by blister.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

Send your message to us

TP8-200A Rotary Packing Machine automatic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords