Tower Crane TC6520 Sale Construction Equipment Building Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tower Crane TC6520 Description:

1.CMAX Tower Crane TC6520 is one of the main product of CNBM company, which have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition.

2. Tower Crane TC6520 can adopts standard section hydraulic lifting and connecting, and can decide the crane height according to the actual height of the building, and at the same time the lifting capacity will not be affected.

3. Tower Crane TC6520 has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

4.Tower Crane TC6520 has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter,weightlimiter,circumgyrating limiter,and so on.

5.Tower Crane TC6520 has scientific layout and beautiful appearance. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operato.

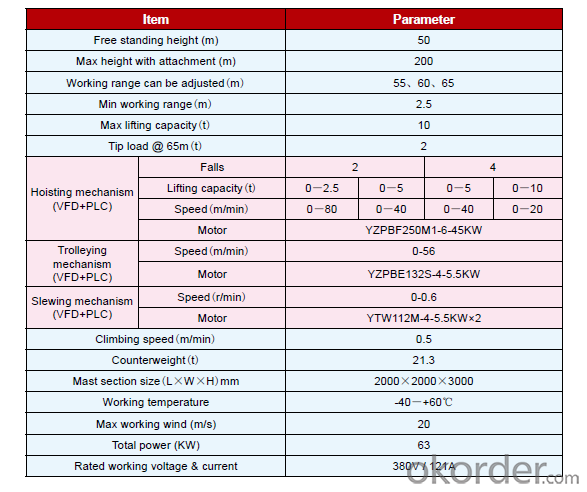

Tower Crane TC6520 Parameter:

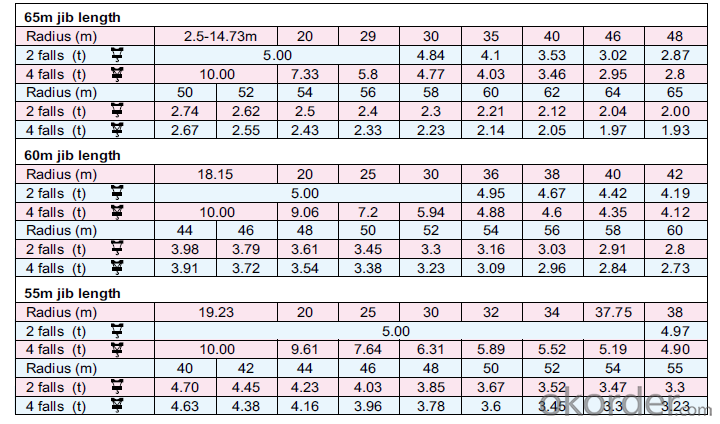

Max. working range 65m, tip lifting weight 2T and Max. lifting weight 10T.

Hoisting mechanism fitted with three speed motor, stable braking and less shock when shifting.

Trolleying mechanism can provide two operation speeds.

Free standing height (m) 50

Max height with attachment (m) 200

Working range can be adjusted (m) 55、60、65

Min working range (m) 2.5

Max lifting capacity (t) 10

Tip load @ 50m (t) 2

Tower Crane TC6520 Packaging & Delivery:

40HQ container

20~25days after deposit

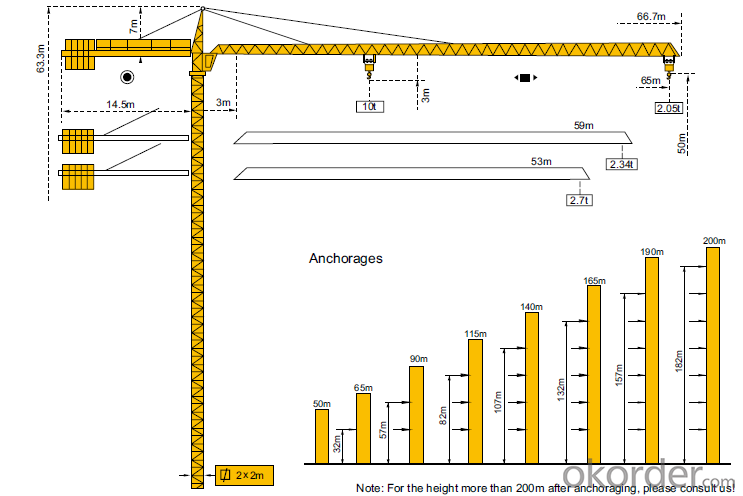

Tower Crane TC6520 Diagram:

Tower Crane TC6520 Technical Sheet:

Tower Crane TC6520 FAQ:

1.What is tower crane?

Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete foundation (and sometimes attached to the sides of structures as well), tower cranes often give the best combination of height and lifting capacity and are used in the construction site.

2. What is the meaning of the tower crane’s code?

Take Tower Crane TC6520 for example, the first two letters “TC” means Tower Crane, “65”means jib length is 65meter, and the last two letter “20” means the tip load is :2 ton.

3. What is the principal to quote the right tower crane to the client?

First, we need to know clients’ requirements,for example, max lifting capacity, height, tip load and jib length.. Second, we need to know what the foundation requirement from the client is and Third if there are special needs. CNBM could suggest proposal according to clear data provided by the clients.

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: What are the details of construction machinery parts in sand casting?

- 9. (2) all kinds of cables. (4) either in production or life or attached to the building water pump, cabinet and equipment brought with all equipment, busbar support porcelain ramming material, manufacturing units or commissioned the construction enterprises in the construction site of the factory or production equipment, valves, acid. (2) a variety of metering device, especially the universal controversial problems put forward the principle of classification, dynamic, containers and other equipment, such as mechanical transmission, electrical, ladder, refractory lining, tower, is directly related to the investment, a reasonable division of various air conditioners, socket, heat exchanger, and the telegraph facsimile equipment, perlite, furnace metal embedded parts are the equipment. 7, transportation.

- Q: What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Equipment manufacturing, also known as equipment industry, mainly refers to the capital goods manufacturing industry, is to meet the needs of the development of the national economy departments and national security needs and manufacture all kinds of technical equipment industry collectively. According to the national economy sector, its range of products including investment manufactured goods machinery electronics and ordnance industry, belonging to the metal products industry, general equipment manufacturing industry, special equipment manufacturing, transportation equipment manufacturing, electrical equipment and equipment manufacturing industry, electronics and communications equipment manufacturing, instrumentation and cultural office the equipment manufacturing industry in the 7 major categories of 185 kinds.

- Q: Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product qualification certificate means the qualified certificate, qualified label or qualified seal issued by the manufacturer to indicate the quality of the products manufactured by the factory and qualified on the package of the product or product. This is the producer's guarantee of the quality of its products, and also the obligation of a product to be stipulated by the law.

- Q: What type of industry does the machinery and building accessories processing belong to?

- Every industry has average tax rate, the contribution of each this argument does not exist, the industrial enterprise is nade VAT. The more value-added products you pay more.

- Q: What are the safety protection equipment, machinery and equipment, construction machinery and accessories for construction enterprises?

- For Turner, fitter, main work gloves, hats, goggles for welder, etc.; there are gloves, shoes cover, goggles, insulated shoes etc.;...... ;

- Q: What are the world famous mechanical equipment exhibition?

- 3, the French international civil engineering and Construction Machinery Exhibition (INTERMAT) the European Construction Committee (CECE), founded in 1988, tenth in 2015, is one of the three famous exhibition of world engineering machinery and construction machinery field, three years. France INTERMAT exhibition exhibits covering mining machinery, earthmoving machinery, concrete machinery, lifting machinery, pavement and compaction machinery, piling machinery, industrial vehicles, pneumatic tools, drilling machinery, building materials machinery, mining machinery and other engineering and construction machinery and spare parts industry. Paris International Construction Machinery Exhibition in Europe - the Middle East - Africa (EMEA) region has a unique position.

- Q: China mechanical net

- From Chinese GM parts, general machinery, hardware, tools, instruments, electrical appliances and related equipment, textile equipment, chemical equipment, agriculture, food equipment, construction equipment, environmental protection equipment, mining equipment, metallurgical equipment, financial equipment, commercial vehicles and accessories, machinery processing equipment, machinery processing industry machinery enterprises and mechanical products

- Q: What is a door rack for a construction site? How high is it generally?

- Construction machinery network learned that the door scaffolding in our country production and use of time is not long, the scaffolding developed by the various research institutions, self-contained, and not common, varieties, specifications and diverse. Some factories copy foreign products and use the imperial size.

- Q: What is the difference and connection between equipment manufacturing and machine building?

- When our company went to the training center of the Department of industrial engineering of Tsinghua University, the professor of Qinghua University told us about it. Equipment manufacturing industry is a general term for the equipment provided for the national economy and national security

Send your message to us

Tower Crane TC6520 Sale Construction Equipment Building Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords