Top safety Electric Wire Rope Hoist

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction

CD1,MD1 model wire rope electric hoist is a kind of light type lifting equipment. It could be installed on single girder crane with hoist, overhead,gantry and jib crane. Modified could be used as a winch. So it is a commonly used lifting equipment in factory, mine, port, warehouse, cargo yard, shop etc, is a nessesary equipment to improve working efficiency and labor conditions.

The lifting speed of CD1 model electric hoist is common speed, it could satisfy common use requirements, MD1 model electric hoist operates two lifting speeds----common speed and slow speed. When working at slow speed, it could satisfy precise loading and unloading, sand box moulding, machine tool inspection and other precise working requirements. So the use MD1 electric hoist would be much wider then CD1 hoist.

It is equiped with compact structure, convenient adjustment, small volumn, light weight, heavy gravity, easy operation etc.

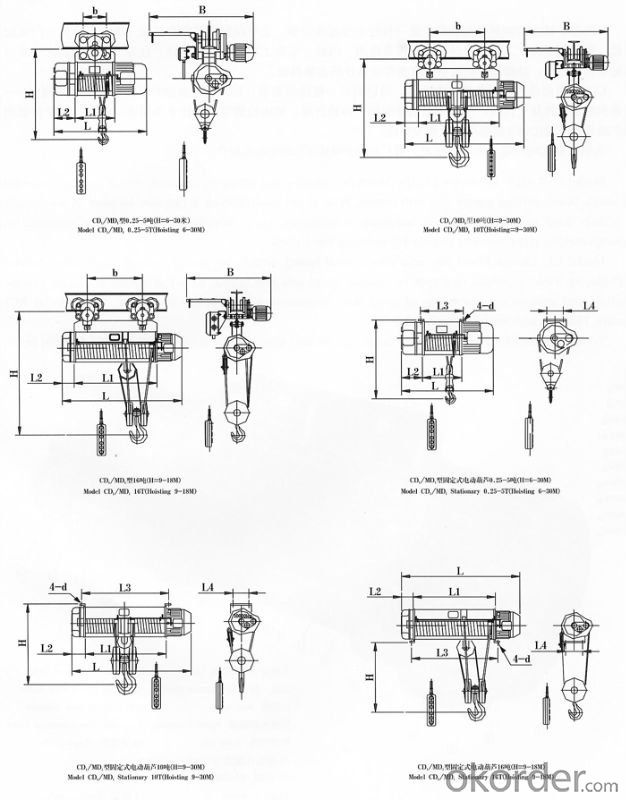

2.Sketch

3.Technical parameter

Model | CD1 MD1(380V, 50Hz, 3p) | ||||||||||||||||||||||

Capacity | t | 5 | 10 | ||||||||||||||||||||

Lift height | m | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | ||||||||||

Lift speed | m/min | 8, 0.8/8 | 8, 0.8/8 | ||||||||||||||||||||

Travel speed | m/min | 20 | 20 | ||||||||||||||||||||

Wire rope | nominal diameter | mm | 14 | 14 | |||||||||||||||||||

Structure | 6×37+NF | 6×37+NF | |||||||||||||||||||||

Intensity grade | MPa | 1770 | 1770 | ||||||||||||||||||||

Traveling track GB/T706-1988 | 28a~63c | 28a~63c | |||||||||||||||||||||

Min curvature radius | m | 2.5 | 3 | 4 | 5 | 2.5 | 3.5 | 4 | 6 | 7.5 | 9 | ||||||||||||

Hoist moto | Model | ZD1 41-4 ZDS1 0.8/7.5 | ZD1 51-6 ZDS1 1.5/13 | ||||||||||||||||||||

Power | KW | 7.5, 0.8/7.5 | 13,1.5/13 | ||||||||||||||||||||

Rpm | r/min | 1380 | 930 | ||||||||||||||||||||

Trolley motor | Model | ZDM1 12-4F1 | ZDM1 12-4F1 | ||||||||||||||||||||

Power | KG | 0.5 | 0.5×2 | ||||||||||||||||||||

Rpm | r/min | 1380 | 1380 | ||||||||||||||||||||

Bonding times | T/H | 120 | 120 | ||||||||||||||||||||

Work duty |

| M3 | M3 | ||||||||||||||||||||

- Q: How is the crane on the construction site built

- To dismantle the tower crane, when building was completed in tower crane to a small crane onto the roof, then, is the contraction of jack will tower crane fell to the roof, and then decomposed into several segments, with a small crane, then small crane break down into smaller components, take the elevator down. When the tower is removed, the ground will be filled with the structure of the tower crane. There is another way is to own a jack will pillar elongation, reoccupy lets own boom lift a scape in, puckering up jack again, and so the scape is getting longer.

- Q: What is a TQ80 tower crane

- The TQ80 is a model of the crane.The very tall thing that we usually see on the construction site.

- Q: Does the electric single-beam crane electric hoist operation need operation certificate?

- Need operation certificate must to technical supervision inspection certification Many people operation It is necessary to establish the corresponding management program And one of them should be operator certificate Otherwise the safety and quality inspection will be trouble

- Q: What is the difference between the beam type and the suspension type of the electric single-beam crane?

- The suspension crane is running on the steel track below the beam.I hope my answer will help you

- Q: What is a crane beam

- The end girder is the part of the cart, connected to the main beam,The walking part of the bridge crane is called the end beam

- Q: The construction crane equipment includes which

- How the lifting equipment works: The elevator is a kind of elevator equipment composed of walking mechanism, hydraulic mechanism, electric control mechanism and supporting mechanism. Hydraulic oil made certain pressure vane pump, the oil filter, flameproof electromagnetic directional valve, throttle valve, hydraulic control one-way valve, balance valve into the lower cylinder, the hydraulic cylinder piston upward movement, improve the weight, the upper cylinder oil return by the flameproof electromagnetic directional valve back to the fuel tank, the rated pressure through the overflow valve adjustment, observing the pressure gauge pressure gauge reading values.

- Q: The difference between a crane, a crane and a crane

- Driving generally refers to the cart and the car of similar type "ten" word or rectangular coordinates in the corresponding projection area of the lifting point. There are also called bridge type crane, beam crane, etc.

- Q: What does the crane main make the controller do?

- The motor capacity is large and the CAM controller is not enough. (2) the frequency of operation is high, and the number of passes per hour is close to or more than 600 times. (3) the crane is heavy and the operation is very frequent, and the requirement of reducing the driver's labor intensity requires the higher life of the electrical equipment. (4) the crane requires better speed adjustment, point motion and other operation performance.

- Q: Why does the crane have two driving rooms? What is the control room in the back? Is there any necessary equipment in it?

- The two driving rooms of the crane are different. The driving room in front of the car (driving speed, direction, etc.).

- Q: What is the lifting torque in construction?

- When buying in tower crane, the relationship between the two types of cranes should be understood, and the hoisting moment curve is carefully compared. The company design, production of QTZ80 can realize three arm length, three kinds of arm length under the condition of nominal torque are shown in table 1: table 1 parameter name parameter values to install arm length (m) 505560 arm side crane load (kN) 15.612.551035 m lifting weight (kN) 25.7124.2822.85 nominal lifting moment (900850800 kN. M) can be seen from the table above and nominal lifting moment arm length. And our national standard is according to the nominal load torque (kN. M), named TC3524 currently in the market, TC4020, TC4516, TC5014, TC5015, TC5312, TC5610, TC5513, TC5612, TC6010 tower cranes are claimed to QTZ80 tower crane, its production cost and purchase price difference is very big. Mastering this is not to be confused by the different Numbers of the same model, making scientific choices

Send your message to us

Top safety Electric Wire Rope Hoist

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches