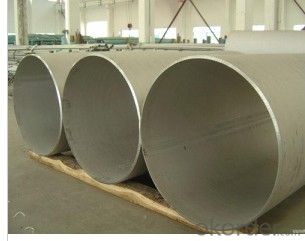

Titanium Tube best quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quality assurance & Inspection

* Chemical analysis

* Mechanical properties

* Bending testing

* Flaring testing

* Flattening testing

* Penetration testing

* Pneumatic testing (optional)

* Hydrostatic testing

* Eddy current testing (optional)

* NDT Ultrasonic testing (depend on specification)

Size of Titanium tube and Pipe

Seamless - OD2.0-219 mm, WT 0.3-8.0 mm, length < 18000 mm

Wedled - OD120 mm and up, WT up to 12.7 mm, length acc. to request

Industrial Applications

Titanium has found a niche in many industrial applications where corrosion resistance is required. Here are some of the common applications of titanium in corrosion resistant service:

Chlorine Chemicals Sea Water

Hydrochloric Acid Sulfuric Acid

Phosphoric Acid Nitric Acid

- Q: Ta18 titanium tube and tc4 titanium tube What is the difference?

- The TC18 titanium tube is more widely used and can be used for landing gear and structural parts, fasteners, brackets, aircraft accessories, frame, beam structure, Pipes and so on.

- Q: Where can I sell TC4 titanium tube / TC4 GR5 titanium alloy tube?

- But if the export can only be Gr5 or Ti6Al4V grades

- Q: Fish tank refrigerator titanium tube evaporator sometimes very loud is how is it?

- Refrigeration when the hand touch the trachea, very cool that the refrigeration system is normal. Not cool, lack of fluoride or system failure

- Q: Whether the titanium tube is resistant to corrosion

- In the reducing acid (such as dilute sulfuric acid solution, hydrochloric acid solution, etc.), due to the oxidation of the oxide film was destroyed, the corrosion rate is faster, and with the increase in temperature and concentration

- Q: Titanium tube bending is in accordance with what standard?

- The most prone to problems is not mechanical properties with chemical composition, but the process performance testing. Sometimes even if all the performance of the process are not qualified, mechanical properties will be no problem. Chemical composition is only to determine the material of the pipe is not in line with Gr.2 requirements

- Q: Titanium tube welding process should pay attention to what?

- Annealing needs to be carried out under vacuum or argon protection, heating temperature of 550-650oC, under the thermostat under the heating temperature, constant temperature 1-4h

- Q: Titanium tube tc4 and gr9 that the pressure

- Gr9 titanium alloy is a low alloying near α titanium alloy, the alloy has good cold forming and welding performance

- Q: What are the main points of titanium tube welding?

- Groove processing, titanium tube cutting, the use of alumina grinding machine grinding out the groove, as shown below, processing groove does not allow the parent material to produce overheating discoloration.

- Q: Consult on the titanium tube expansion of the problem

- Welded tube in the bar under the control of poor control of the case, it is prone to cracking situation

- Q: Titanium tube is ta1 material, titanium rod is ta2 material?

- TA1 is pure titanium greater than 99.6% titanium is collectively referred to as TA1 (grade)

Send your message to us

Titanium Tube best quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords