Tinplate For Paint Cans, MR/SPCC Material, BA/CA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Brief Introduction about our company

Our company is one largest state owned company and one largest tinplate supplier in China. Our annual output reaches more than 500,000 tons, both BA & CA, SR&DR. Now we have more than 10 overseas warehouses in the world, such as UAE, Saudi Arabia etc.

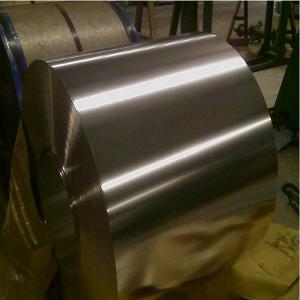

2. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

3. Our production steps

4. Usage Scope

5. Our euxport market

our tinplate has been popularly exported to more than 30 countries, including Asia, Europe countries, Gulf area, Sounth America, Northe & South Afric etc.

6. FAQ

a. what’s your company name?

our company named CNBM international corporation, we are both one large state owned company and tinplate supplier in China

b. where your mill situated?

Our head office is in Beijing, while our mill in Hebei province.

c. how about the delivery time?

usually 55~65 days after receipt advance payment or original LC;

d. what payment term you accept?

Our payment term is very feasible, such as TT, DP, LC at sight, LC after sight etc.

e. can you offer MTC?

Of course, we will issue MTC after each shipment, for customer reference and testing if some quality issue appears.

- Q: Can tinplate be used for promotional or gift packaging?

- Yes, tinplate can be used for promotional or gift packaging. Tinplate is a versatile material that is durable, visually appealing, and can be easily customized with various designs. It offers a premium look and feel, making it an excellent choice for creating attractive promotional or gift packaging that can leave a lasting impression on recipients.

- Q: How does tinplate contribute to the overall portability of packaging?

- Tinplate contributes to the overall portability of packaging due to its lightweight yet durable nature, making it easy to transport and handle. Additionally, its excellent resistance to corrosion and ability to preserve the quality of the packaged product ensures that packaging remains intact during transportation, further enhancing its portability.

- Q: Can tinplate packaging be used for personal care products?

- Yes, tinplate packaging can be used for personal care products. Tinplate is a durable and versatile material that provides excellent protection for various products, including cosmetics, lotions, and other personal care items. Its ability to resist corrosion and maintain the product's quality makes it a suitable choice for packaging in the personal care industry.

- Q: What are the main applications of tinplate in the paint industry?

- Tinplate is commonly used in the paint industry for packaging purposes. It is primarily used for manufacturing paint cans, which provide a durable and protective container for storing paint products. Tinplate cans also offer excellent resistance to corrosion and airtight sealing, ensuring the longevity and quality of the paint. Additionally, tinplate cans are easy to handle, stack, and transport, making them a convenient choice for the paint industry.

- Q: How does tinplate compare to glass packaging?

- Tinplate packaging offers several advantages over glass packaging. Firstly, tinplate is significantly lighter than glass, making it easier and more cost-effective to transport. Secondly, tinplate is more durable and less prone to breakage, reducing the risk of damage during handling and storage. Additionally, tinplate provides better protection against light and oxygen, ensuring the contents inside remain fresh and unaffected. Lastly, tinplate is highly recyclable, making it a more sustainable choice compared to glass packaging.

- Q: How does tinplate perform in high humidity environments?

- Tinplate performs well in high humidity environments due to its corrosion resistance properties. The tin coating on the steel substrate acts as a barrier, preventing moisture from reaching the metal surface and causing corrosion. Therefore, tinplate is an excellent choice for packaging and other applications in high humidity conditions.

- Q: How does tinplate perform in terms of mechanical strength and durability?

- Tinplate is known for its excellent mechanical strength and durability. It is highly resistant to bending, denting, and breaking, making it ideal for various applications where strength is crucial. Additionally, tinplate is highly durable and can withstand harsh environmental conditions, including corrosion and rust. Overall, tinplate is a reliable and long-lasting material in terms of mechanical strength and durability.

- Q: How does tinplate perform in terms of fire resistance?

- Tinplate has poor fire resistance as it is made of thin steel coated with a layer of tin, which can easily melt or deform under high temperatures, making it susceptible to fire.

- Q: How has tinplate evolved over the years?

- Tinplate has evolved significantly over the years in terms of its production process, durability, and applications. Initially, tinplate was made by coating iron sheets with a thin layer of tin to prevent corrosion. However, as technology advanced, electroplating replaced the traditional hot-dipping method, resulting in a more efficient and cost-effective production process. Additionally, the development of various alloy coatings has further enhanced the durability of tinplate, making it more resistant to rust and damage. Moreover, tinplate has expanded its applications beyond traditional cans, finding its way into packaging for food, beverages, aerosols, and cosmetics. Overall, the evolution of tinplate has revolutionized the packaging industry, offering improved quality, versatility, and sustainability.

- Q: Why tin tin plating?

- Tin is the famous "hardware" - one of gold, silver, copper, iron and tin. As early as in ancient times, people discovered and used tin. A number of ancient tombs in China, they often find some tin pot, like tin tin candlestick. According to research, China's Zhou Dynasty, the use of tin has been very common. In the ancient tombs of Egypt, tin articles were also found.

Send your message to us

Tinplate For Paint Cans, MR/SPCC Material, BA/CA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords