Tinplate Coil and Sheet for Metal Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Tinplate Coil and Sheet for Metal Packing Description

Packaging Details: | Prime T3 Tinplate in sheets with Seaworthy Standard with wooden pallet |

Delivery Detail: | Prime T3 Tinplate in sheets delivery time 10-30days |

2. Main Features of the Tinplate Coil and Sheet for Metal Packing

Our company engaged in steel products ,including prepainted galvanized steel coil/sheet,galvanized steel coil, cold rolled steel coil/sheet,seamless steel pipe,galvanized pipe,angle iron,steel beam etc.

Quality has been in the industry for more than 10 years.We have been trusted by domestic owned companies,,as well as international distributors and renowned brands,such as Haier,Kia and Beijing Hyundai etc.We put quality as lifeline.We never manufacture or sale defected products,or lowering our price at the cost of products quality.

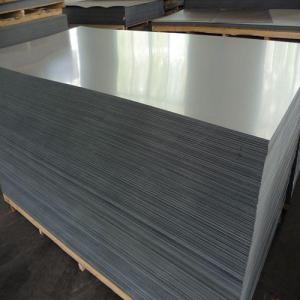

3. Tinplate Coil and Sheet for Metal Packing Images

4.Tinplate Coil and Sheet for Metal Packing Specification

Product name | Prime T3 Tinplate in sheets |

Steel Type | SPCC, MR |

Temper(BA&CA) | T1~T5 |

Coating for the Prime T3 Tinplate in sheets | 1.1~11.2g/m2 |

Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) |

Width & tolerance | 300~1000mm (Tolerance: 0~3mm) |

Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) |

Coil inside diameter | 420/508mm |

Coil Weight | Prime T3 Tinplate in sheets weight 3~10 MT |

Passivation | 311 |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matte |

Packaging | Prime T3 Tinplate in sheets with Seaworthy Standard with wooden pallet |

Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 |

5. FAQ of Tinplate Coil and Sheet for Metal Packing

How can I buy SLM products in my country?

Please send us an inquiry or email,we will reply to you if there is distributor in your country.

- Q: How does tinplate packaging contribute to product protection against leakage?

- Tinplate packaging contributes to product protection against leakage primarily due to its durable and corrosion-resistant properties. The tin coating on the steel substrate prevents any contact between the product and the surrounding environment, minimizing the risk of leakage. Additionally, tinplate packaging is often manufactured using advanced sealing techniques, ensuring airtight and leak-proof closures. Overall, the robust nature of tinplate packaging serves as a reliable barrier, safeguarding the product from potential leakage and preserving its quality.

- Q: What are the advantages of using tinplate for pharmaceutical packaging?

- There are several advantages of using tinplate for pharmaceutical packaging. Firstly, tinplate is highly resistant to corrosion, ensuring the integrity and safety of the pharmaceutical products. Secondly, tinplate provides excellent barrier properties, protecting the contents from moisture, light, and oxygen, which can degrade the quality and efficacy of medications. Additionally, tinplate is sturdy and durable, providing adequate protection during transportation and storage. Finally, tinplate is easily recyclable, making it an environmentally friendly choice for pharmaceutical packaging.

- Q: How does tinplate compare to plastic in terms of durability?

- Tinplate generally offers better durability compared to plastic as it is more resistant to breaking, cracking, and bending. Additionally, tinplate is less prone to wear and tear, making it a more long-lasting material.

- Q: How is tinplate coated for furniture?

- Tinplate for furniture is typically coated through a process known as electroplating, where a thin layer of tin is deposited onto the surface of the furniture. This process involves immersing the furniture in a solution containing tin ions, and then applying an electric current to facilitate the deposition of the tin onto the surface. This coating provides the furniture with a protective layer, preventing corrosion and enhancing its aesthetic appeal.

- Q: How does tinplate packaging contribute to product shelf life?

- Tinplate packaging contributes to product shelf life by providing a protective barrier against moisture, light, and oxygen, which helps to prevent spoilage, oxidation, and degradation of the product. This type of packaging also enhances product stability, preserves freshness, and extends the overall shelf life, ensuring that the product maintains its quality and integrity for a longer period of time.

- Q: Can tinplate packaging be used for aerosol products?

- Yes, tinplate packaging can be used for aerosol products. Tinplate is a commonly used material in aerosol can production due to its durability, resistance to corrosion, and ability to withstand the pressure exerted by aerosol content. Additionally, tinplate cans can be easily shaped and decorated, making them suitable for various aerosol products in the market.

- Q: How does tinplate perform in terms of magnetic properties?

- Tinplate exhibits poor magnetic properties as it is a non-magnetic material.

- Q: Does tinplate affect the taste or quality of food?

- Yes, tinplate can affect the taste and quality of food. Tinplate containers or cans may sometimes impart a metallic taste to the food, especially acidic or highly seasoned products. Additionally, if the tin coating is damaged or corroded, it can lead to chemical reactions with the food, potentially compromising its quality and safety.

- Q: How does tinplate contribute to the overall stackability of packaging?

- Tinplate, being a lightweight and durable material, greatly contributes to the overall stackability of packaging. Its rigid structure ensures that the packaging can be safely stacked without collapsing or damaging the contents. This allows for efficient use of storage space and easy transportation, making tinplate an ideal choice for stackable packaging solutions.

- Q: What are the different ways tinplate packaging can be decorated?

- Tinplate packaging can be decorated in various ways including printing, embossing, debossing, hot stamping, and applying labels or decals. These methods allow for customization and branding, making the packaging visually appealing and attractive to consumers.

Send your message to us

Tinplate Coil and Sheet for Metal Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords