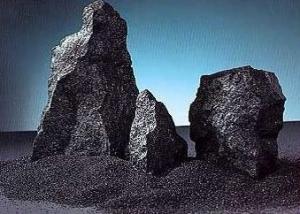

Raw Materials for Refractory:Tilting Brown Fused Alumina with SiO2:1.3

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Henan, China

· Shape: Block or grain size or powder

· Material: Alumina

· Al2O3:95%min

· SiO2:1.3%max

· TiO2: 3%max

· Fe2O3:0.3%max

· CAO:0.6%max

· MGO:0.3%max

· K2O+Na2O:0.3%max

· B.D:3.8g/cm3min

· MOI:0.2%max

· Refractoriness (Degree):1770°< Refractoriness< 2000°

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy and Refractory

· Product name: Brown Fused Alumina

· Color: Brown

· Size:50MESH/100MESH/200MESH/325MESH/0-1MM/1-3MM/3-5MM/0-40MM

· BULK DENSITY:3.8g/cm3min

· Certificate:ISO9001

· Usage:Fire Resistance Place

· Type:Raw Refractory

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, you only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check our other products in website.

- Q: What materials is silicious thermal insulation board made of?

- Siliceous insulating panels use quartz sand as the main material and are composited with fiber. Of course the amount of insulation board materials used by different companies is different. In terms of Hua Heng, siliceous insulating boards can be divided into insulating panels for casting slabs and insulation board for intermediate tank according to the usage. The latter one can be divided into liner plate (wallboard, side panels, baseboard) and impingement plate based on parts it is used on. Siliceous insulating panels use quartz sand as the main material and are composited with fiber. Method for manufacturing a silicon insulating panel is divided into semi-dry method and wet method. It is used for casting ingot insulation cap of the killed steel and continuous casting tundish.

- Q: What kinds of fireproof and fire retardant materials are there?

- What kinds of fireproof and fire retardant materials are there? What is the criteria for making fireproof and fire retardant materials?

- Q: What's the difference between refractory metal raceway and fireproof raceway?

- Fire protection slot won't cause fire accident under the temperature of no more than 200℃. While the refractory cable tray is made with refractory materials and can withstand high temperature of 800℃ with no fire accident happening. The test standard depends on the maximum temperature it can endure. Hope it's helpful for you!

- Q: what's the classification of fireproof and thermal inuslation matertial?

- Inorganic thermal insulation material can do it, such as glass wool,rock wool,foam glass,etc. phenolic foam materials in organic foam material is special. phenolic foam not only has good thermal insulation properties but also can be composited with steel plate and other materials, A class thermal insulation materials that reach A class combustion performance include: rock (mine) wool, foam glass, EVB, etc. thermal insulation materials with A class combustion performance mainly include: phenolic aldehyde,gelatine powder polyphenyl granule, etc. thermal insulation material of fire barrier zone can use rock (mine) wool, foam glass, EVB and other materials with A class combustion performance.

- Q: Who knows about the fire endurance of sintered shaly hollow bricks?

- Sintered shaly hollow bricks of Chu area have high intensity. The average compressive strength of them is up to 15.8, which matches with M7.5 cement mortar that has advantages of low water absorption, and good anti efflorescence performance. The fire endurance of sintered shaly hollow bricks should not exceed1050 degrees otherwise they will burn excessively. I, actually, think that the temperature should be controlled within 980 degrees. I hope my answer may help you.

- Q: What is refractory aggregate?

- Refractory aggregate is fire-resistant product improved with low temperature binder, chemical?compound and normal temperature strength.

- Q: Which brand of refractory fiber hard thermal insulation board is better?

- Thermal insulation materials are divided into two types: porous material and heat reflecting material. The former uses the air void contained in the material to maintain thermal insulation itself for the heat conductivity coefficient of air or inert gas within the voids is low, such as foam material, fibers and other materials; the latter material has a high coefficient of reflection which can reflect the heat, such as gold, silver, nickel, aluminum foil or metallic coated polyester and polyimide thin films. Aerospace industry has strict requirement for the weight and volume of thermal insulation material, and it is often also required to has the properties of noise absorption, vibration attenuation, and anti-corrosion. Different aircrafts have different requirements for thermal insulation materials. Aircraft cabin and cockpit usually use foam, ultra-fine glass wool, high silica cotton to maintain thermal insulation. Earlier missile head uses phenolic foam plastic as thermal insulating material. With the application of polyurethane foam with good thermal endurance, the single insulating material has been developed to sandwich construction. A few millimeters foaming coating is coated on the skin outside the missile instrument bay, it is anti-corrosion coating at room temperature and when aerodynamic heating reach 200 ° C or more, it will generate foam evenly thus maintaining thermal insulation. Artificial earth satellite moves in an environment where the temperature varies from high to low, so it must use laminated thermal insulation material with high reflecting performance, which is usually made up of dozens of layers of aluminum film, aluminized polyester film, and aluminized polyimide film. In addition, the successful development of the surface thermal insulated tiles has solved the problem of thermal insulation of the space shuttle, it also marks a higher level of development of insulation materials.

- Q: Who knows about the types of Dalian thermal insulating and refractory materials?

- There are mainly following types: rock wool series, rubber and plastic series, glass wool series, mesh series, ventilation series, mortar series, extruded sheet series, geothermal series, insulation supporting pin series, glass silk cloth series. I hope my answer can help you.

- Q: What refractory materials are used in power plant

- And then I will introduce some application of thermal material in power plant (below) I hope I can help you. Energy saving is the trend of future industrial development efforts, grinding machine, conveyor belt, so the production of light thermal insulation materials will gain state support, drying kiln. Our factory mainly produce light thermal insulation brick. The refractory material we use most is light insulation brick, and the equipment used is sand mixer (Luohe, Henan)

Send your message to us

Raw Materials for Refractory:Tilting Brown Fused Alumina with SiO2:1.3

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords