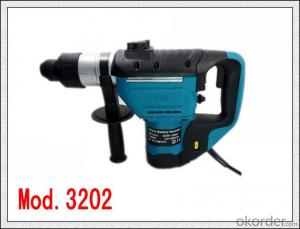

three functions 28mm damping Hammer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Model: Z1C-SG-28

Type: two slots two pit

Drilling diameter : 28 Rated

Impact rate at rated speed:4000(bpm)

Speed: 800 (rpm)

Power supply type AC power 1500 (W)

Maximum drilling diameter 28 (mm)

Technical Parameters

Standard models : Z1C-SG-28 Order number : 2801

Voltage : 110V / 220V Frequency : 50 / 60Hz

Speed : 800r / min drilling diameter : 28mm

Motor : Copper wire casing colors: red + silver glitter

Packaging: Packaging Accessories Kit : Reference Annex Figure

Packing Size : 45X38X36 Number of units : 3 sets / pieces

Standard models : Z1C-SG-28 Order number : 2801

Voltage : 110V / 220V Frequency : 50 / 60Hz

Speed : 800r / min drilling diameter : 28mm

Rated Power : 1500W

Motor : Copper wire casing colors: red + silver glitter

Packaging: Packaging Accessories Kit : Reference Annex Figure

Packing Size : 45X38X36 Number of units : 3 sets / pieces

- Q: The real hammer must have a cylinder?

- Using compressed air hammer is relative with the cylinder structure, but also through the gas power into rotary motion, such as work by cam structure. Generally, this device is called a pneumatic motor.

- Q: BOSCH three hammer hammer drill is not only what is the reason?

- No, it's your knob. It doesn't work properly. If you transfer to the location, it does not change the working state. That's the adjusting gear inside. It's broken.

- Q: The electric hammer drills drilling iron will function with what bit

- Another point to note, because the concentricity of the hammer drill is not high, the drill drill swing things badly, is not easy to drill at the same time, because of the drill chuck before and after the virtual is relatively large, so almost drilled when before the punch, causing danger, suggest to buy a separate electric hand drill, good use safety.

- Q: Hammer can drill wood?

- It's for one use only. Not a single piece of wood, hammer drill is used for drilling, wood is a multifunctional electric hammer drill on the function, you need to install the card head. The drill bit for drilling wood basically consists of a carpenter's twist drill. Carpenter's flat drill. And there's the hole drill. There are generally used metal drill bit: straight twist drill drilling, such as Bing, handle drill, milling cutter and so on.

- Q: Why not hammer drill iron

- The characteristics of the electric hammer drill:1, a good shock absorber system: allows the operator to hold comfort, relieve fatigue.The way to realize is realized by vibration control system;Through the soft handle increased comfort grip;2 、 accurate speed control switch: when the touch switch is lower, it can help the machine to drill smoothly (for example, drilling on the smooth surface of tile, not only prevents the drill from slipping, but also prevents the hole from breaking. High speed can be used during normal work to ensure efficiency.3, stable and reliable safety clutch: also known as the torque limiting clutch, avoid large torque during use due to seizure caused by the reaction of bit transfer to the user, this is a kind of safety protection of users. This feature also prevents the gears and motors from stopping rotating.Motor protection device 4, comprehensive: in use will inevitably have hard granular access to a machine (especially on the machine to work on drilling, such as drilling on the top wall), if there is no certain motor protection, rotating at high speed can easily be hard break or scratch enameled wire, resulting in motor failure.5, positive function: can make use of a wider range of electric hammer drill, the form is mainly realized through switch or adjust the brush position, usually big tools will be used to adjust the brush position (rotating brush) to achieve the benefits of doing so is easy to operate, effectively inhibit the spark to protect motor commutator, prolong the use life6, hammer drill double function: both the impact hammer, electric drill and penetration.

- Q: Hammer hit the cement wall do not move

- First, make sure that the walls can be knocked out, not the load-bearing walls, beams, or columns.

- Q: How to use a hammer

- Drilling operation(1) pull the work knob to the "drilling" (not hammer) position.(2) place the drill in the hole where it is to be drilled and then pull the trigger switch. You can jog.

- Q: Hammer choose what precautions

- The choice of bits depends on the nature of the work. Often used are: tungsten carbide cement bit, tungsten carbide cross drill, pointed chisel, flat chisel, ditch chisel. Tungsten carbide cement bit is mainly used for drilling various strength grades of concrete, and the most commonly used specifications are diameter 5 ~ 38mm.

- Q: How to distinguish the hammer is a dual purpose, that the use of dual sign.

- The dual-purpose charged shovel, shovel will not turn, can only play group, most willing to use the line tick wall, above a knob, the hammer is a special drill

- Q: Is it useful to hammer reverse function

- It is the reverse clockwise and counter clockwise, common in electric drill and electric hammer tool. For example, electric drill, screw, with positive turn, screw and reverse. With a positive reversal for the electric light electric hammer (such as BOSCH products), it is possible to install the adapter operation with the drill chuck, so with a positive reversal. Even if you drill with an alloy drill, you can easily reverse it if you get stuck.

Send your message to us

three functions 28mm damping Hammer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

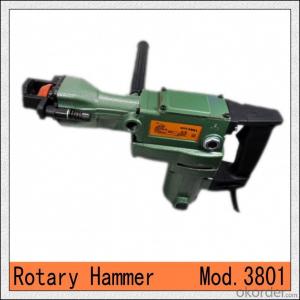

Similar products

Hot Searches

Related keywords