Three cone drill bit loader

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

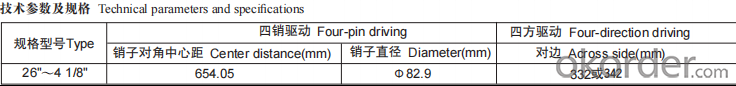

Specification

Three cone drill bit loader

Drill bit unloader is a tool specifically used for screwing and removing drill bits at the wellhead, also known as a drill bit unloader.

purpose

The main purpose of a drill bit loader is to assist technicians in screwing and unloading drill bits at the wellhead during oil or gas drilling processes. The design of this tool aims to simplify the process of replacing drill bits, improve work efficiency, and reduce the workload of operators.

advantage

The main advantages of drill bit loaders include improving loading and unloading efficiency, reducing operational risks, adapting to various specifications of drill bits, and enhancing operational safety.

The drill bit loader should be selected according to the size of the drill bit to ensure that the loader can firmly clamp the drill bit without causing additional damage to the drill bit.

Secondly, the following points should be noted during the operation process:

Before using the drill bit loader, it should be checked to ensure that it is intact and free from cracks or damage.

When loading and unloading drill bits, excessive force should be avoided to avoid damaging the drill bit loader or drill bit.

The operation should be carried out smoothly, avoiding sudden jerking or pulling to prevent crushing the drill bit or loader.

Finally, other precautions include:

When storing drill bits, they should be moisture-proof, ventilated, and avoid colliding with the cones and threads.

When using drill bit loaders, relevant safety operating procedures should be followed to ensure the safety of operators.

- Q: What tools are used for hand engraving?

- Engraved chapter, to seal the lid seal material is indonesia. With the different seal for document printing inks. Mainly in the leaves Indonesia fiber, cinnabar and castor oil as the basic raw material, made of fine processing. Good seal the inkpad stamp, vivid color pigmentation, with stereo feeling, not oil leakage, eye-catching writing is clear. Indonesia except red, there are a variety of special inks. Such as green, black, brown, blue and so on.

- Q: How do you cook tools manually?

- There are complete sets of toys in the toy shop, and vegetables. I bought one. You can go and have a look. The price is not expensive.

- Q: Can you tell me what hand tools are punched on the instrument box? No electric drills

- Not the kind of drill with drill bit, it is operated by hand. There are two moulds up and down. But 6mm did not die, you still use a drill, less than 1mm thick good open, you can use the speed motor, is to use the awl can pierce the first tie a proper hole, and then slowly rest, neither shaking and do not spend money.

- Q: What tools do you need to make a handbag?.

- First of all, according to the template (which I bought online, a little expensive, just a few copies of the paper, more than 20 pieces) Draw the leather with a silver pen, then cut it.

- Q: Screwdriver and "wrench" is the same tool?

- NoScrewdriver, screwdriverLu s d a o, Lu s Q from ZiA [screwdriver] used to turn the screws to force the tools in place, there is usually a thin wedge head, the screw head can be inserted into the slot or recess -- also known as the "screwdriver". The main word (minus) and cross (plus two).

- Q: What are the brands of hand tools?

- STANLEY, Black & Decker, Sata, yingzhiyin, liyide, AFP Jujian, STANLEY Black & Decker is the world's best, the best is Star

- Q: A hand painted coloring tool

- Mark pen: we use the usual color tools, the color is extremely detailed, Mark pen has a variety of characteristics, such as transparency, softness, and so on. The use of Mark pen will be more bright and shiny, but also more convenient than watercolor, gouache.

- Q: Makeup expert, about the use of foundation tools

- James finished liquid foundation after the next step is to set makeup, makeup powder (powder), cannot use the hand painted, you have to use puff tools, can also use the makeup brush large, gently brush on the face, so the effect will be a little lighter.

- Q: What tools do you usually use for hand making?

- If it is fabric, basically need: cloth, scissors (preferably cutting cloth scissors), needles, lines. (other things depend on the needs of the work. These materials are required.)

- Q: What kind of power tools are hand drills? 1, 2 or 3?

- In the prevention of electric shock protection, in addition to relying on basic insulation, but also the need for zero protection.

Send your message to us

Three cone drill bit loader

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches