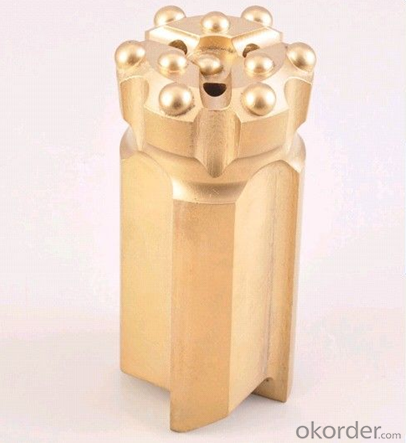

hot selling thread button bit T45 T51 retrac body

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are specialized in rock drilling tools,such as taper button bit, thread button bit, Integral drill rod, DTH bit, DTH hammer, Air leg rock drill, Excavator Mounted rock driling and splitter, expansive mortar.

Product:

Thread Button Bits: High quality and several thread with various carbide tips like YK05 are available. All products can be developed upon customers' request. Premium designs and steel and premium tungsten carbide insert grade T6 supplied by Boart Long year, Offers industry-leading strength and penetration rates for more productivity, Excellent straightness and hole clean quality, Get max. drilling performance for rock drills with long life to save up fuel cost rate.

Description of button bit:

Our company supply all kind of button bits with Rope thread

R32-43MM, R32-45MM, R32-51, R32-64, R32-76;

T38-64, T38-76MM, T38-89, T38-102MM;

T45-76MM, T45-89MM, T45-102MM;

T51-89MM, T51-102MM, T51-127MM etc.

all face design, flat face, drop-center face, normal body and retrac body.more

Specification of button bit:

Thread | Diameter range | Skirt Design | Face Design | Button Design |

R22 | 35 – 45mm | Normal | Flat Face | Hemispherical |

R25 | 33 – 57mm | Normal | Flat Face | Hemispherical |

R28 | 36 – 51mm | Normal | Flat Face | Hemispherical |

R32 | 41 – 89mm | Normal | Flat Face | Hemispherical |

R35 | 48 – 51mm | Normal | Flat Face | Hemispherical |

R38 | 64 – 102mm | Normal | Flat Face | Hemispherical |

T38 | 57 – 102mm | Normal | Flat Face | Hemispherical |

T45 | 70 – 127mm | Normal | Flat Face | Hemispherical |

T51 | 76 – 140mm | Normal | Flat Face | Hemispherical |

T60 | 89 – 140mm | Normal | Flat Face | Hemispherical |

ST58 | 89 – 140mm | Normal | Flat Face | Hemispherical |

GT60 | 93 – 140mm | Normal | Flat Face | Hemispherical |

ST68 | 102 – 152mm | Normal | Flat Face | Hemispherical |

Company Profile:

CNBM is the largest state-owned enterprise in China building material & equipment industry. Up until October of 2011, our total assets exceeded RMB 190 billion, with 130,000 employees and over 300 subordinate companies. In the year 2012, we are ranked as No. 365 in World Top 500 Enterprises by Fortune, and No. 2 in global building materials industry, second only to Saint-Gobain.

FAQ:

1. Q: Can I get some samples?

A: We are honored to offer you samples for quality check.

2. Q: Do you have the products in stock?

A : Yes , We have sample for several models now could supply to you.

3. Q: What’s the delivery time?

A: It usually takes about 25 days to produce an order. But the exact delivery time might be different for different orders or at different time.

4. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. Rock drilling tools workers always attach great importance to quality control from the every beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

6. Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. Our company is world top 500, that is the biggest supplier and manufacture in China, having a good reputation around the world.

7. Q: What's the payment you accept ?

A: As usual our payment is T/T, other payment can consider.

As the largest manufacturer and exporter of building materials in China, we avail ourselves of this opportunity to approach you for mutual-beneficial cooperation. If you want to know more, pls contact me freely.

- Q: New drills usually need sharpening before they can be used. Why?

- We monitor only a bit grinding blade; another edge to teach short, and a big pot. The hole is 60 millimeters deep; this is called a folk prescription, and the drill hole is asymmetric. The hole will appear in the big hole. If there is any deviation between the two sides of the deep hole, the drill will be drilled

- Q: What are the differences between the center drill and the twist drill in its structure and use?

- Center drill: prefabricated, precise positioning for hole processing and central hole machining on end faces of shafts and shafts. Guide the twist drill to reduce the error.

- Q: What is a square hole drill and can be machined square hole?

- You can drill through the square hole, but not once.

- Q: Small bit drilling, drilling machine speed is fast or slow?

- The main reason for the large size is the asymmetry of the sides of the drill. Also, do not drill directly with such a large drill. First drill with a small bit, then use a larger bit to expand the hole

- Q: How big is the screw hole at the back of the torch chuck? Is it a rebound?

- If the chuck is to be assembled, stop the spindle from turning, and some have a rectangular edge that clamps the parallel edge with a thin, corresponding opening.

- Q: What does the cutting depth of the drill mean 3D?

- That is, the diameter ratio of the drill, such as 3D, and the diameter of the drill is 20MM, the effective drilling depth is 60MM

- Q: How about the speed of the drill bit and the feed of the cutter in the machining center?

- 1, if I first drill with D13 bit (S600, F80, Q5), and the rest of all milling cutter hole2, casting and steel parts almost turn, the speed can be faster. After 28 of the hole points, use 28 bit S300, F50, Q3. directly3, 35r6 direct spiral down, layer below 0.5-0.8, S1500, F2000-3000

- Q: Why do you always burn drills?

- If it's made of stainless steel, there's also a drill, a cobalt white drill, which I've often used, though expensive, but super durable. If the ordinary drill, the speed of 500 to 800 minutes, on the high burning.A class of white steel line, color grinding when not, point to be around 118, as high temperature resistant. The speed is about 1000.

- Q: How do you tell which materials are used in the test?

- Cutting different materials depends more on the shape of the cutting edge. Different cutting edges are used for different materials. Experience is very important. Take a look at the schematic diagram of the drill edges.

- Q: An expansion screw with a diameter of 20. How much impact bit do you need to use?

- The table above is the reference value of the match;2, the specific adaptation, also need to be flexible according to the actual situation, if the fixed place expansion screw is loose, need to be reduced if the fixed impact drill specifications; expansion screws tight place, according to the above table match.

Send your message to us

hot selling thread button bit T45 T51 retrac body

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords