The suction nozzle bag

- Loading Port:

- Shekou

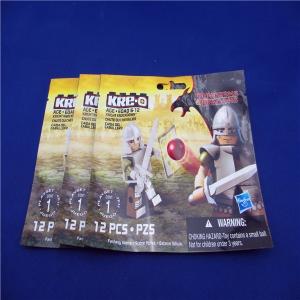

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100.0000PCS cm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Can be customized

1. According to customer design requirements, printing 1 ~ 9 color on the bag, copperplate printing.

2. Bag composite materials can be divided into: PET outside the OPP. Matte film. Nylon

PET aluminum plating in the middle. CPP aluminum plating. Pure aluminium. Paper. Pearly membrane

In PE. CPP

Shrinkable film PVC, PET

Customers can choose materials according to their own product packaging requirements.

3. The bag type can be divided into: 3-side. The sealing bag. Organ bag. Zipper bag. Erect bag. Zipper bag. Bag mouth. Heterotypic bag. Card bag. Shrinkable film, etc.

4. Features: shading. Sealing strong. High-grade beautiful. Leakproof. High temperature resistant. Antistatic, etc.

5. Apply to: food factory. Electronics factory. Pharmaceutical companies. Confectioners. Cosmetics company. Health care products company. Toy factory, etc.

6. The unit price: according to the customers' final materials.. The thickness of a few color printing. Quantitative calculation for standard price.

- Q: The package specifications are 9 multiplied by 14 plus 3. How big is it?

- Now the standard of living has improved, basically vacuum packed bags. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- A good vacuum packing is recommended.

- Q: Why a lot of the packaging bag surface is silver foil?

- Because of the use of aluminum foil can effectively prevent light barrier light, plastic packaging and direct food through accelerated food spoilage.

- Q: What is the material for edible fungus stick packing bag?

- HDPE bags, which are not high temperature resistant, can be sterilized at 104 degrees. Over this temperature, the contamination rate of pathogens will be increased.

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!

- Q: What is the difference between LDPE and PE-LD in a package?

- LDPE is a low density polyethylene, environmental protection bag production is one of the raw materials, commonly known as low material, another raw material of HDPE is also called high pressure materials, packaging film, the two materials are mixed according to a certain proportion and then blowing, printing, cutting, packing bag made of,PE-LD is a common environmental protection mark printed on top of the packing bag, which indicates that the manufacturer is using an environmentally-friendly plastic bag.

- Q: What material is the packing bag for pure milk, please?

- General milk packaging is basically Tetra Pak packaging or Kang Mei package, aluminum foil about 5% of the quality of the entire package, about 79% of the paper, polyethylene layer of about 16%. Because the aluminum foil, polyethylene layer and paper layer are bonded by hot pressing or adhesion, it is difficult to separate the layers. Learn1986 (in station contact TA) these two documents may be useful to you.

- Q: Is there any identification on the vacuum package?

- DOD on demand machine (drop) for short, called ink jet printer. The working principle: the nozzle is made up of several high precision valves. When the word is sprayed, the corresponding valve is opened and closed quickly. The ink is ejected by the constant internal pressure, forming characters or graphics on the surface of the movement.

- Q: What material should be used for transparent packing bags? How many cents do you want?

- PVC, English referred to as PVC (Polyvinyl chloride), is a vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in peroxide, such as azo compound initiator; or in light, under the action of heat polymerization by free radical reaction mechanism of polymerization of polymers. The vinyl chloride homopolymer and vinyl chloride copolymer are collectively referred to as vinyl chloride resins.

- Q: What kind of packaging bag does polysilicon use?

- Disposable material into a double-layer polyethylene bag, and then packing bags into the packing box or packaging barrel. Block polysilicon packaging specifications are net 5000g or 10000g per bag.

Send your message to us

The suction nozzle bag

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100.0000PCS cm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords