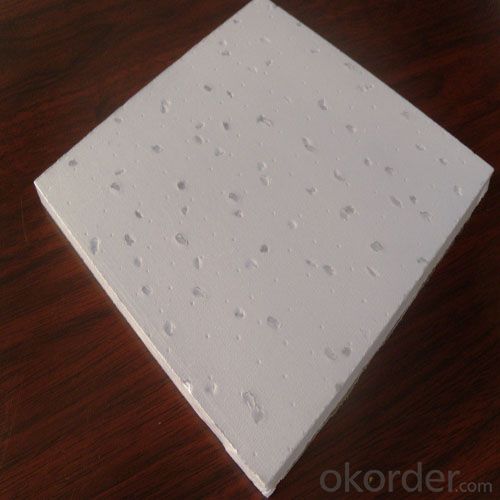

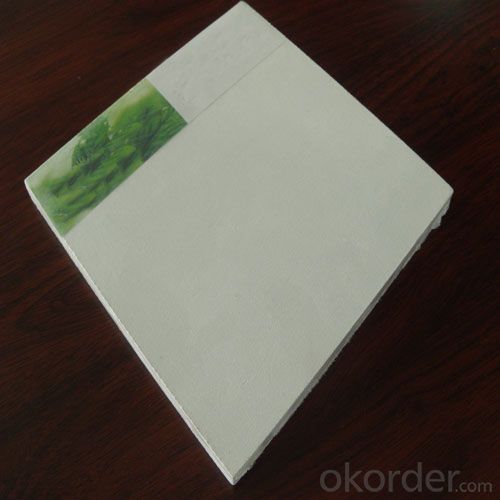

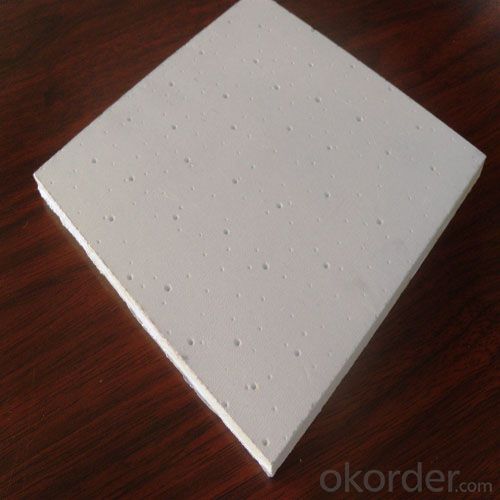

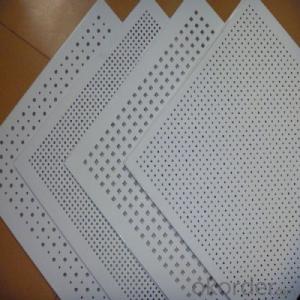

Textured Gypsum Ceiling Panels for Suspension

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

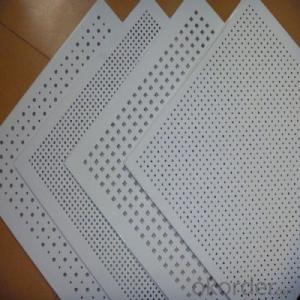

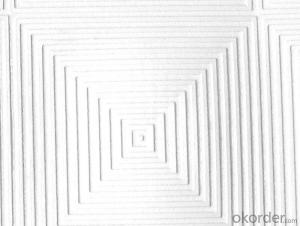

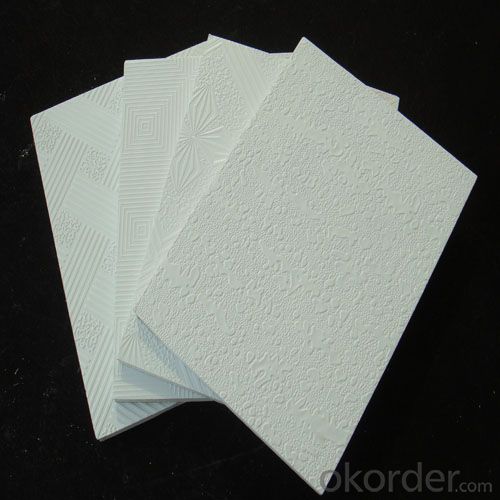

Gypsum Board Ceiling Tiles.

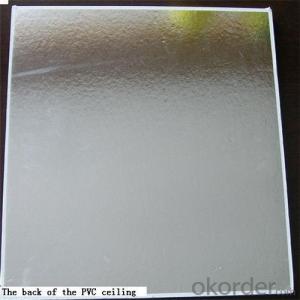

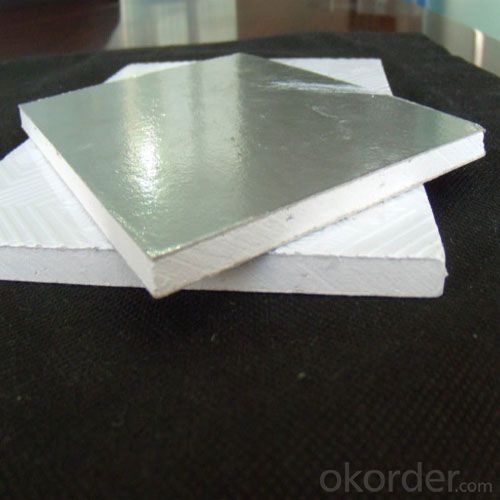

Plaster board with one side vinyl PVC facing and backside with aluminium foil.

Size: 595x595mm, 603x603mm, 605x605mm, 610x610mm, 595x1195mm, 604x1210mm, 605x1210mm ,610x1220mm.

Thickness: 7.00mm, 7.50mm, 8.00mm, 9.00mm, 10.00mm, 12.00mm, 12.50mm

Various colorful PVC patterns; Light weight; Easy for installation;

Materials | Gypsum Board |

Surface | PVC and Aluminum Foil |

Allow Dimension Difference | Length ≤±2.0mm |

Weight Kg/m2 | Width ≤±2.0mm |

Thickness ≤±0.5mm | |

< 6.5kg/m2 | |

Strength | Break Load>150N |

Containing Water Rate | < 1% |

Fireproof Class | Class B1 Meet the standard:GB8624-1997 |

Moisture Requirement | Under 90% |

Production Capacity: 10, 000, 000 sq. Mt/year

Payment: T/T or L/C.

Price term: FOB Qingdao(CIF or CNF)

Unit Price/Payment: USD

Transportation: By 20'Container

Loading port: Qingdao port

HS Code: 6809190000

Origin: Shandong, China

Packing: Carton, 8PCS/carton or according to customers' demand

Shipment: Within 20days after receipt of the deposit of T/T, L/C;

Minimum Order: 1x20ft container

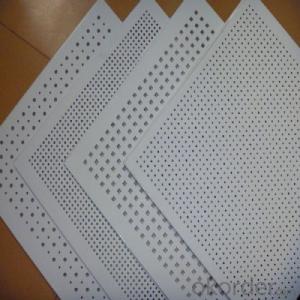

There are 51 different colorful pvc patterns and 31 vinyl pvc for you to select.

- Q: What is the difference between the PU angle and the gypsum angle?

- PU angle is imitation gypsum, cheaper than gypsum, easy to use, moisture, insulation, moth, etc., classified in high-grade decorative materials

- Q: Decoration company strongly suggested that with calcium silicate board, said a little bit more expensive than the gypsum board, waterproof fire better than gypsum board, and will not fall off the powder. But I found the Internet, but found that almost no calcium silicate board for the family ceiling, and some calcium silicate board which contains carcinogenic asbestos. And the elderly think that this calcium silicate board, commonly known as cement board, the quality is heavier, hanging on the ceiling always feel insecure, how can I do in the end?

- Asbestos is carcinogenic This you can check online, with carcinogenic asbestos China not to use, in China so that the use of chrysotile asbestos, you can check in Chrysotile on the interpretation of the other do not explain

- Q: Gypsum board ceiling life long? Home furnishings gypsum board ceiling can be used to maintain long?

- Ten years should be possible

- Q: Gypsum board ceiling how to set the inspection mouth?

- Usually in the construction process there are several places we are required to open the mouth (of course, this is only for closed ceiling), such as: the ceiling has a valve position, water supply and drainage inspection or repair nozzle, hidden distribution box And other hiding hydropower equipment and components such as accessories.

- Q: The house is engaged in decoration, the balcony has been installed on the ceiling, but the workers said that four nails hanging in the "gypsum ceiling" fixed on the fixed, I had gypsum board door in advance also set a wooden grid, but due to gypsum board barrier, Can not see the wooden lattice, the workers said, "Ghost know that my four nails nail up, will be tied in the air or wood? Think about it also makes sense ah, but I really want to be a drying rack on the balcony ah ~ ~ Otherwise, after life more inconvenient? ~

- Gypsum ceiling can not take `` Gypsum shock at least to crack the `

- Q: Corridor gypsum ceiling calculation area method

- According to the expansion area, the length of the plane plus the length of the long ride, long by the width is the flat area, high from the original ceiling down to the lowest end of the gypsum board height, for example, the ceiling size is 6 meters long 2 meters wide, from the original ceiling hanging down 0.3 meters. The calculation method is: (6x2) + (6x0.3) hope to help you

- Q: Gypsum board secondary ceiling generally out how much

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other properties of better building materials, is currently focused on the development of one of the new lightweight sheet. Gypsum board has been widely used in residential, office buildings, shops, hotels and industrial plants and other buildings within the wall, wall panels (instead of wall plaster layer), ceilings, sound-absorbing panels, ground floor boards and the Such as decorative plates.

- Q: Gypsum board ceiling, when digging holes, and installation should be noted

- After the end of the overall renovation, to the installation of the project can be tapped when the hole.

- Q: Ward to the top how to paste plaster line

- Wardrobe to do from the top 10 to 15 cm distance, in the above take a block of 10 to 15 cm cap. Look specifically at the width of your corners. If there are 20, then stay a little more. Above the door to open the door, it is also recommended long and short

- Q: Home decoration in the ceiling to do light, the distance from the top ah?

- Ceiling (English name: sprung roof) refers to the housing living environment of the top decoration. Simply put, refers to the decoration of the ceiling, is an important part of interior decoration. Ceiling with insulation, insulation, sound insulation, sound absorption of the role, but also electrical, ventilation and air conditioning, communications and fire, alarm pipeline equipment and other projects hidden layer. Home decoration ceiling is a common part of home improvement. The ceiling is different according to the material of the decorative plate, and the classification is not the same. Ceiling decoration materials is the main basis for distinguishing the name of the ceiling, mainly: light steel keel gypsum board ceiling, gypsum board ceiling, mineral wool board ceiling, plywood ceiling, profiled long strip of aluminum slab ceiling, Glass ceiling, aluminum honeycomb perforation sound-absorbing panels such as ceiling. In the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

Send your message to us

Textured Gypsum Ceiling Panels for Suspension

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords