Termite-repellent and Rodent-repellent Nylon Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nylon compound:

1. Competitive price

2. Customized products

3. Stable quality

4. 30 years of experience

Nylon compound:

1. Applications of Nylon compound:

Nylon jacket compound for non flame retardant optical fiber cable, communication cable and power cable with well performance of low temperature resistance and resistance to brittleness, substitute for imported No.12 nylon jacket compound.

2. Descriptionof Nylon compound:

This nylon jacket compound is developed by ourselves, in order to substitute for the PA12. It has a lot of advantages, such as processing easily, low temperature brittleness resistance, smooth surface, termite-repellent and rodent-repellent. It is suitable for jacket with low temperature brittleness resistance.

3. Processing of Nylon compound:

The compound can be processed with conventional extruders. The L/D should be greater than or equal to 25; and the compression ratio of screw should be greater than 1:2.5.

Drying: be dried at 85-100°C for 3-6 hours before use.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

temperature °C | 230 | 245 | 245 | 240 | 240 | 240 |

Note: The above temperature is recommended only, and the actual processing temperature should be according to the type of machine and environment.

4. Storage and transport of Nylon compound:

Packaging:25kg/bag,Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties of Nylon compound:

Item | Unit | PA1012-A | PA1012-D |

Standard | Standard | ||

Density | g/cm3 | 1.1 | 1.1 |

Hardness | ≥Shore D | 60 | 60 |

Tensile Strength | ≥MPa | 50 | 50 |

Elongation at Break | ≥% | 180 | 180 |

Notched Impact Strength | ≥KJ/m2 | 30 | 30 |

Volume Resistivity | ≥% | 1.0×1012 | 1.0×1012 |

Dielectric strength | ≥MV/m | 24 | 24 |

Oxygen Index | — | — |

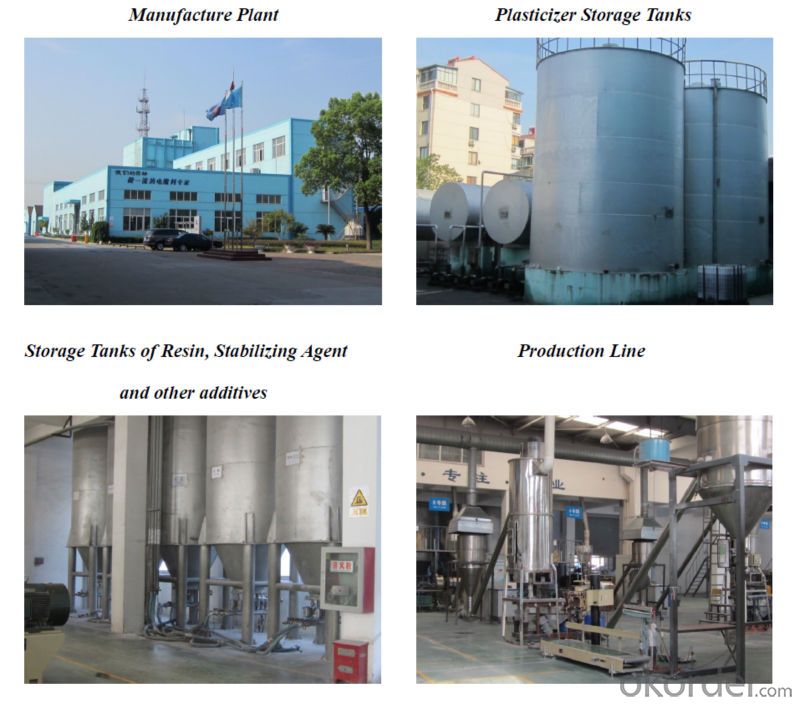

6. Company

- Q: What plastic material has great impact resistance?

- The ability of metal materials, machinery parts and components to resist impact damage is called impact strength.

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- EPS is a foaming agent that is used to make foam, which is the white foam that is packed in the TV and refrigerator.

- Q: How many kinds of plastic do you have?

- B. foam:Foam plastics can be divided into three kinds of hard, semi hard and soft foam. Hard foam without flexibility, compression hardness is very big, only up to a certain stress deformation, stress the lifting of restitution; soft foam rich flexibility, compression hardness is very small, very easy to deformation, stress release after can restore the residual deformation small; semi rigid foam between flexibility and other properties between hard and soft foam.

- Q: What is the disposable transparent plastic cup?

- PMMA: commonly known as acrylic, transparent material, its surface hardness is slightly lower, easy to wipe flowers. It is suitable for making transparent insulation parts and general strength parts

- Q: What type of raw material is used in plastic bags? The brightness is good. It blows out as bright as a mirror! That kind of transparency!

- LDPE high pressure 2424H, Lanzhou petrochemical, LLDPE, 7042N, Lanzhou petrochemical. Transparency can reach 90%. The temperature should be controlled during blowing.

- Q: What is plastic film material?

- Plastic film material is plastic micelle, which is made by petrochemical enterprises from petroleum refining.

- Q: Will plastic raw materials (such as PET, PP, etc.) be made of non-woven fabrics, will certainly contain BPA?

- Only PC (polycarbonate) is available.If the customer is not sure, you can take your product to the third party organization testing, prove that you can do without BPA, and ask your supplier to provide inspection reports and guarantee without BPA.

- Q: ABS plastic storage conditions

- Plastic materials generally react with light and oxygen for a long time to become yellow and brittle

- Q: What kind of plastic material is used for medical instruments?

- The resin used for medical plastic requires higher purity and narrower molecular weight distribution;

- Q: Is plastic raw material rubber?

- Raw materials are polymers of polymers such as polypropylene. Is generally from the fossil raw materials inside the extraction after polymerization together. A series of plastic refers to the resin as the main component, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials. To put it simply, the oil was extracted and finally made into plastic, rubber and plastic

Send your message to us

Termite-repellent and Rodent-repellent Nylon Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords