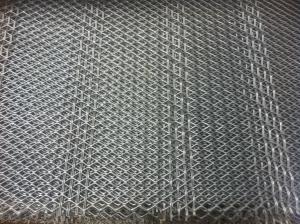

Stainless Steel Wire Mesh Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material:

201,202,302,304,304L,316,316L

Guage:

1.wire diameter:0.1-3.0mm

2.Mesh: 1-650mesh.

3.Width:0.5-5m

3.Length:30m

Weave way

Dutch weave

Plain weave

Twill weave

Stainless steel wire mesh kind:

1, stainless steel plain weave mesh. 2, stainless steel twill mesh. 3, stainless steel mesh bamboo pattern. 4, five mechanized stainless steel mesh. 5, stainless steel perforated metal mesh. 6, stainless steel crimped wire mesh. 7, stainless steel chain link fence. 8, stainless steel mesh. 9, stainless steel welded wire mesh. 10, stainless steel hexagonal. 11, stainless steel I-Net. 12, stainless steel wire meshes. 13, stainless steel mine screen. 14 mesh stainless steel shells.

- Q: What is the role of steel pipes in the mining and extraction of minerals?

- Steel pipes play a crucial role in the mining and extraction of minerals. They are widely used in various mining operations to transport water, slurry, and other fluids, as well as to provide structural support and ventilation in underground mines. One of the primary uses of steel pipes in mining is for transporting water or slurry. Water is essential in the mining process for various purposes, such as dust suppression, ore processing, and site rehabilitation. Steel pipes are used to create a network of pipelines that transport water from a source, such as a dam or reservoir, to different areas within the mine site. Similarly, slurry, a mixture of water and crushed minerals, is often transported through steel pipes to processing plants or tailings dams. Steel pipes also play a critical role in providing structural support in underground mines. Underground mining operations require tunnels and shafts to access valuable mineral deposits. These tunnels and shafts need to be reinforced to withstand the immense pressure exerted by the surrounding rock and prevent collapses. Steel pipes are used as support structures, such as roof bolts and rock bolts, to reinforce the walls and roofs of these underground excavations, ensuring the safety of miners and the stability of the mine structure. Additionally, steel pipes are used for ventilation systems in underground mines. Proper ventilation is vital in mining to ensure a constant supply of fresh air, remove harmful gases, and control temperature and humidity levels. Steel pipes are used to create ventilation shafts and ducts that facilitate the flow of air throughout the mine. This helps maintain a safe and healthy working environment for miners by preventing the buildup of toxic gases, dust, and heat. In summary, steel pipes are indispensable in the mining and extraction of minerals. They are used for transporting water, slurry, and other fluids, providing structural support in underground mines, and facilitating ventilation systems. Without steel pipes, the efficient and safe extraction of minerals from mines would be significantly hindered.

- Q: What are the specific differences between flexible pipes and rigid pipes?

- Choose from the waterproof performance:A rigid waterproof sleeve is a steel pipe with an outer wing (a steel ring made of a steel ring), mounted in the wall (mostly concrete walls), used for general pipe wall crossing, and is beneficial to the waterproof of the wall;The flexible waterproof casing except external wing ring, flange ring and internal wire like, and have complete sets sold, but also their own processing, for pipeline damping needs, such as pipes and pumps connected through walls.

- Q: How are steel pipes used in the manufacturing of heat exchangers?

- Steel pipes are commonly used in the manufacturing of heat exchangers due to their strength, durability, and ability to withstand high temperatures and pressures. These pipes are typically used to create the primary heat transfer surfaces within the heat exchanger, allowing for efficient transfer of heat between two fluids. The steel pipes are often arranged in a coil or tube bundle configuration, providing a large surface area for heat exchange to occur. Additionally, the corrosion-resistant properties of steel make it an ideal choice for handling various fluids in heat exchanger applications.

- Q: Can steel pipes be used for transporting drinking water?

- Yes, steel pipes can be used for transporting drinking water. Steel pipes are commonly used in water distribution systems and have been used for many years. They are known for their durability, strength, and resistance to corrosion. However, it is important to ensure that the steel pipes used for transporting drinking water are properly coated or lined to prevent any potential contamination from the metal. Additionally, regular inspections and maintenance should be carried out to ensure the integrity of the pipes and to prevent any leaks or breaks that could compromise the quality of the water.

- Q: How are steel pipes used in the manufacturing of structural frameworks?

- Steel pipes are commonly used in the manufacturing of structural frameworks due to their strength, durability, and versatility. These pipes are used as components in the construction of frameworks, such as buildings, bridges, and towers, providing support and stability to the overall structure. Steel pipes are often used to create columns, beams, and trusses, which are essential for bearing heavy loads and ensuring the structural integrity of the framework. Additionally, steel pipes can be easily welded, allowing for efficient and cost-effective construction processes. Overall, steel pipes play a crucial role in the manufacturing of structural frameworks by providing a robust and reliable solution for various construction projects.

- Q: What are the safety measures to be followed while working with steel pipes?

- Some safety measures to be followed while working with steel pipes include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against cuts, burns, and falling objects. It is important to inspect the pipes for any defects or damage before handling them and to use proper lifting techniques to avoid strain or injury. Additionally, workers should be trained on how to properly use cutting and welding equipment to prevent accidents or fires. Regular maintenance and inspections of tools and equipment should be conducted to ensure their safe operation.

- Q: Seamless steel pipe 8162 and 8163 what is the difference?

- GB 8162 is the structure of the tube, there is no need for flaw detection, the use of mechanical processing, stents;

- Q: What are the common applications of seamless steel pipes?

- Seamless steel pipes have a wide range of applications in various industries. Some common applications include oil and gas exploration and transportation, construction and infrastructure projects, automotive manufacturing, power generation, and chemical processing. They are also used in industries like aerospace, telecommunications, and pharmaceuticals where high precision and reliability are required. The seamless design of these pipes ensures superior strength, durability, and resistance to corrosion, making them suitable for demanding environments and critical applications.

- Q: How do you prevent steel pipes from freezing?

- To prevent steel pipes from freezing, there are several measures you can take: 1. Insulate the pipes: Use foam insulation sleeves or wrap the pipes with insulation tape. This will help maintain the temperature of the pipes and prevent them from freezing. 2. Seal any gaps or cracks: Inspect the area around the pipes and seal any gaps or cracks with caulk or expanding foam. This will prevent cold air from entering and freezing the pipes. 3. Install heat cables: Heat cables can be wrapped around the steel pipes to provide a steady source of heat. These cables can be controlled by a thermostat, ensuring that the pipes stay above freezing temperature. 4. Keep the temperature above freezing: In areas where extreme cold weather is common, it is advisable to keep the indoor temperature above freezing, even if the property is vacant. This will help maintain a suitable temperature for the pipes and prevent freezing. 5. Open cabinets and faucets: In particularly cold weather, open cabinet doors in kitchens and bathrooms to allow warm air to circulate around the pipes. Additionally, allowing faucets to drip slightly can also prevent freezing by keeping water flowing. 6. Drain the pipes: If you are leaving your property unoccupied during freezing weather, it is recommended to drain the pipes completely. This can be done by shutting off the main water supply and opening all faucets until no water remains. This minimizes the risk of freezing and potential damage. Remember, prevention is crucial in protecting steel pipes from freezing. By implementing these measures, you can significantly reduce the risk of frozen pipes and potential costly repairs.

- Q: Are steel pipes resistant to impact or external forces?

- Yes, steel pipes are generally resistant to impact and external forces. Steel is known for its high strength and durability, making it an ideal material for various applications, including pipes. Steel pipes have the ability to withstand external forces such as impact, pressure, and vibrations. They are often used in industries that require reliable and sturdy piping systems, such as oil and gas, construction, and infrastructure. Additionally, steel pipes are less prone to cracking or breaking under extreme conditions compared to other materials. However, the resistance to impact and external forces may also depend on the specific grade and thickness of the steel used in the pipes.

Send your message to us

Stainless Steel Wire Mesh Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords