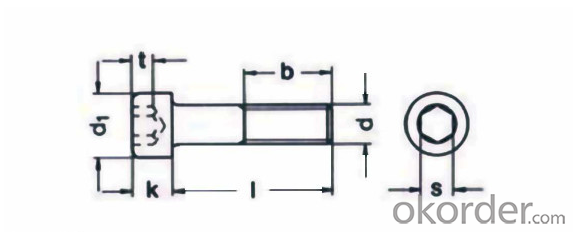

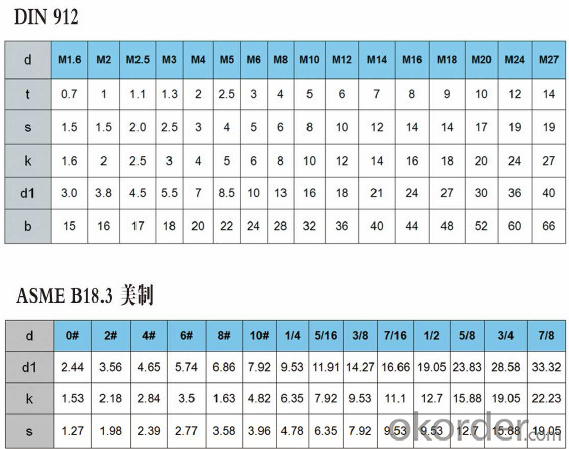

STAINLESS STEEL SOCKET HEAD CAP SCREW DIN912

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,the description of our main products :

The series of standard parts, stainless steel machine screws, self-tapping screws, outside hexagon screws, hex socket screws, set screws, nuts, Taiwan teeth, plain washers, spring washers, hole with elastic ring, shaft with elastic ring, open ring, gasket, different designs American-made inside and outside hexagon, top wire, nuts, mini screw; 12.9 Taiwan imported alloy steel of high strength screw; Allen wrench, ring spanner.

Non-standard processing: according to drawings, standards, sample processing.

GB, JIS, , DIN, ANSI/ASME,BS, ISO.

2,the application of the stainless steel screws

Electronics, medical equipment, hardware, mechanical, Marine, chemical industry, communications, construction, etc.

3,products show

3,stainless steel socket head cap screws

4,FAQ

Q: WHAT ARE YOUR ADVANTAGES?

A: 1. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. 2. We have a strict quality control from production to delivery. 3. We take use of advanced system and tool to improve working efficiency and control every step. 4. Professional sales team to serve customers. 5. Samples can be provided as your requirements. 6. Professional packing team which keep every packing safely.

Q: WHAT ARE YOUR MAIN PRODUCT?

A: We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip / Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube / Stainless Steel Pipe Sheets.

Q: CAN I GET FREE SAMPLE?

A: YES. We can provide free sample. However, you should be responsible for the transportation freight. Please tell us your express account or please send us the transportation freight of samples firstly, then we can arrange sample delivery.

Q: HOW MUCH THE TRANSPORTATION FREIGHT WILL BE FOR THE SAMPLES?

A: The freight depends on the weight and packing size and your area.

- Q: The idiom of the screw

- Lei Feng: I would like to always make a screw, a person's role, for the cause of the revolution, as a machine on a screw machine as a result of the many screws and fixed, only to become a solid whole, can Run freely, play its great ability to work. Although the screw is small, its role is not underestimated. I would like to make a screw hello forever. Screw to regular maintenance and cleaning, it will not rust. People's thinking is the case, to always check will not go wrong

- Q: What tools are used to remove the screws, the two lines are grooves, the middle of a paragraph is convex

- As for the professional name is not clear, probably should be called forked screwdriver it

- Q: Screws are not slopes.

- Yes, the inclination of the object can be seen as a slope This can be seen as a slide, the slide is a slope. The slope is a simple machine. The screw is screwed into a cylindrical slope, the thread on the screw is like the pattern formed in Figure (A), the length of a circle of threads is equivalent to the length of the slope.

- Q: I'm talking about another thing

- Screw is the use of objects of the circular circular rotation and friction of the physical and mathematical principles, step by step to fasten the tools of the tools. Screws are the general terms of fasteners, daily oral language

- Q: What does the screw m4x6 mean?

- M for the flat wire (not self-employed screw) 4 for the diameter, 6 for the length. Units are generally millimeters

- Q: Why are the screws of the screw?

- I have not heard the concept of non-standard thread, because the thread is used to assemble, so the lathe in the car thread, the amount of feed and other parameters are given.

- Q: Who knows who invented the screw?

- Greek mathematician Archimedes invented the thread, but until the 15th century only appeared the first screw, do not know who is its inventor. 1550 years with wood screws, until 1774 only invented a screwdriver. In 1936, Henry M. Philips applied for a patent for the screws of the crosshead head

- Q: I am a trainee apprentice, recently encountered a problem, that is, some screws are screwdriver screwdriver or hexagon turned no thread. Can not buckle, only in the inside idle. What is the general use of this situation to open it? Thank you, more urgent.

- It seems that you do not call the thread. It seems nothing better way. You can drill a little deep groove ah

- Q: How is the screw produced

- There are three types of technology: cold heading, red, turning; rolling teeth generally have four kinds of technology: rubbing teeth, rolling wire, teeth, car teeth; but our screw industry is the most common Is the beginning of the cold heading, the machine rubbing teeth, so that large output, low cost

- Q: How to remove the broken screw?

- Thick (5 or more) easy to handle, playing a hole with a dedicated wire on the line. Fine can be trouble, it is better to just re-drilling tapping.

Send your message to us

STAINLESS STEEL SOCKET HEAD CAP SCREW DIN912

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords